| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Custom Metal Brackets |

|---|---|

| Brand Name: | Xiange |

| Model Number: | MBC-XG-1 |

| Certification: | ISO 9001:2015 SGS RoHS |

| Place of Origin: | China |

| MOQ: | 1 pcs |

| Price: | USD 1$-2$ |

| Payment Terms: | T/T, Western Union, MoneyGram |

| Supply Ability: | 10 SET per week |

| Delivery Time: | 5-8 days |

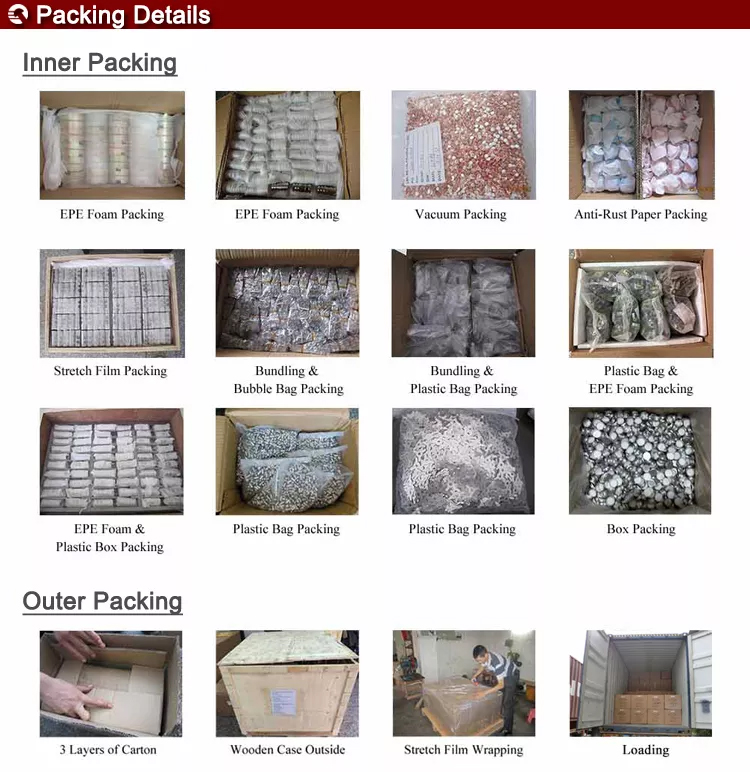

| Packaging Details: | Carton Wooden case |

| Material Capabilities: | Stainless Steel,Aluminium,Copper,Brass |

| Products name: | Metal Bracket Components |

| Process: | Metal sheets fabrication,Welding Cutting Punching Stamping |

| Application: | metal plastic parts |

| Tolerance: | +/-0.01mm |

| MOQ: | 1 Piece |

| OEM/ODM: | Acceptable |

| Equipment: | Precision Nonstandard Parts |

| Crafts manship: | Metal sheet fabrication,CNC stamping,CNC bending,Welding |

| Applications: | Automotive,Medical,Telecom,Construction,machine etc |

| Material: | stainless steel,aluminum |

| Company Info. |

| Shenzhen Xianheng Technology Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Custom Bracket Aluminum Stainless Steel Bending Stamping U Shelf Sheet Z Shaped metal Brackets Components

Our Features and Advantages

HLC METAL PARTS LTD(HLC) is a professional manufacturer of metal

parts. We are technical in the development and design of precision

tooling and the production of precision metal parts

(such as precision casting, stamping, CNC machining metal parts)

and plastic parts. We also provide assembling and fitting service

of metal and plastic accessories. HLC has a number of outstanding

and professional management and technical employee. With principle

of “High Quality, Low cost, Superior service” , we focus on

maintaining high standards in technology, quality, service and

management aspects.

| Item | Description |

| Product Name | stamping part,Metal Bracket Components |

| Working Process | stamping, deep stamping, bending, punching, threading,welding, tapping, riveting |

| Material | Stainless steel, carbon steel,copper, brass, and bronze (according to customer's requirements) |

| Surface Treatment | hot galvanized, polishing, Zinc-plated, nickel-plated, chrome-plated, silver-plated, gold-plated, imitation gold-plated, powder coating, etc. |

| Packing | Inner-Plastic Bag; Outer -Standard Carton Box. |

| Usage | All kinds of cars, machinery, home appliance, electronic products, electric appliance, stationery, computers, power switches, miniature switches, architecture, commodity and A/V equipment, hardware and plastic molds, sports equipment and gifts, and more |

| Quality Control | Conducted by ISO/TS16949:2002 and ISO14001:2004 system. |

| Equipments | CNC stamping/punching machine, CNC bending machine, CNC cutting machine, 5-250T punching machines, welding machine, polish machine |

| Applications | auto,motorcycle,industry,ariculture,mine,furniture,elevator,etc |

| Thickness | 0.5mm~12mm, or other special available |

| File Format | Solidworks,Pro/Engineer,Auto CAD,PDF,JPG |

| Service | Warm and quick response service provided by the professional Export Sales Team with many years' experience in handling exports to the US, Europe, Japan and other countries and regions. |

| Inspection | IQC, IPQC,FQC,QA |

Description

1. Over 12 years exerience in metal stamping parts

2.Facility:Stamping machines,automatic stamping machine,punching machines,Oil Hydraulic pressing machines,bending machines,welding machines, meter lathes

3.Material:Carbon steel(cold rolled steel sheet,galvanized steel sheet or tube),stainless steel,copper ,brass,aluminum,etc

4.Finish:zinc plated,chromated plated, Electrophoresis, Dacromet ,powder painting,etc

5.Industries:Funiture hardware, electronic hardware,construction machinery parts,metal processing machinery parts.

6.Standard:OEM manufacturing as per customers requirements.

| Industry Range | What we can Provide |

| CNC Machining Service | Turning, Milling, Stamping, Bending, Welding, Tapping, Riveting, Gear cutting, Wire-cutting, etc |

| Sheet Metal Service | |

| Home Appliance Prototype | Refrigerator, Washing Machine, Microwave Oven, Hair Dryers, etc. |

| Auto Part Prototype | 1:1 or 1:10 Car Model, Auto Parts, Bumper, Dashboard, Car Lamp, Motorcycle, Scooter, Bike and etc. |

| Medical Device Prototype | Scanner Case, Ultrasonic diagnostic imaging care etc. |

| SLS/SLA 3D Printing Service | Custom SLA SLS custom 3D printing service |

| Vacuum Casting | Low MOQ customization service |

| Material Acceptable | |

| Stainless Steel | SS201,SS301, SS303, SS304, SS316, SS416 etc. |

| Steel | Mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. |

| Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc |

| Plastic | ABS, PC, PE, POM, Delrin, Nylon, PP,PEI, Peek etc. |

| Copper | C11000,C12000,C12000 C36000 etc. |

| Iron | A36, 45#, 1213, 12L14, 1215 etc. |

| File Formats | Pro/E, Solidworks, Unigraphics, Catia, Auto CAD.(*.stp,*.igs,*.sldprt,*.stl,*.x-t.*CATPart) |

The process starts with a cad file – a digital copy of the final design intended for the part. Depending on the manufacturing process, sheet metal can be cut on a laser cutting machine that uses pre-programmed instructions to guide the cutting tool path. Alternatively, parts are made using one or more laser cutting, milling, shaping, bending, punching, cutting, or stamping processes.

Sheet metal parts can have simple or complex geometries. Affordability, scalability and a wide choice of materials make sheet metal fabrication popular in several industries. It is widely used in the manufacture of housings, brackets and chassis for parts.

Stamping bending parts

laser cutting parts

Sheet metal fabrication products:

OUR ADVANTAGES

Advanced 5-axis CNC and imported processing We have multiple CNC machining machines, skilled

equipment with an accuracy of ±0.02-0.10 mm production workers, guarantee fast lead times

We will protect the customer's design and the We have a strict quality inspection process to

customer can request a confidentiality agreement. ensure the quality of our products.

Q:Can I have a trial order or samples only for several pieces?

A:Of course! Free sample can be provided, you only need to pay for shipping cost.

Q:Can you open mold for us to manufacture new product?

A:Yes! If the quantity is big, our company can afford part of the mold cost.

Q:How long is your delivery time?

A:Generally it is 3-5 days if goods are in stock. Or it is 7-30 days if the goods are not in stock, it is according to your quantity.

Q:Can you provide after-sales services?

A:Definitely! 100% before and after-sale service with quality .

Q:What is your terms of payment?

A:T/T, PayPal, VISA, E-Checking, MasterCard.

Q:How can I get the quotation?

A:Please send us information for quote: drawing, material, weight, quantity and request,we can accept PDF, ISGS, DWG, STEP file format.

If you don’t have drawing, please send the sample to us,we can quote base on your sample too.

o

|