Waste organic fertilizer production line

Waste Organic Fertilizer Granulating Production Line

Introduction of waste organic fertilizer granulating production

line

Waste organic fertilizer granulating production line is mainly used

to produce different organic fertilizers that are derived from

animal waste, agricultural waste,industrial waste and kitchen

waste,etc.It not only reduces environment pollution,but also makes

rational use of resources.

Benefits of waste organic fertilizer granulating production line

After safety disposal and fermentation,raw materials are made into

bio-organic fertilizers that contain a variety of organic acids,

peptides and rich nutrients including nitrogen,phosphorus and

potassium.Organic fertilizers not only provide comprehensive

nutrition for plants and crops,also with long fertilizer effect,

which can increase and update the soil organic matter,promote

microbial breeding,and improve soil chemical and physical

properties and biological activity.

Raw Material for waste organic fertilizer granulating production

line

1.Kitchen waste:pericarp,vegetable leaves and eggshell,etc.

2.Agricultural waste:corn stalk,rice stalk,wheat straw,Mushroom

residue,etc.

3.Municipal sludge:industrial sewage,water supply sludge and river

sludge,etc.

4.Industrial waste:vinasse,begass,biogas residue,vinegar

residue,Bean dregs,etc.

5.Animal waste:chicken manure,duck manure,pig manure,cow dung,horse

dung,sheep manure,etc.

Working Process of waste organic fertilizer granulating production

line

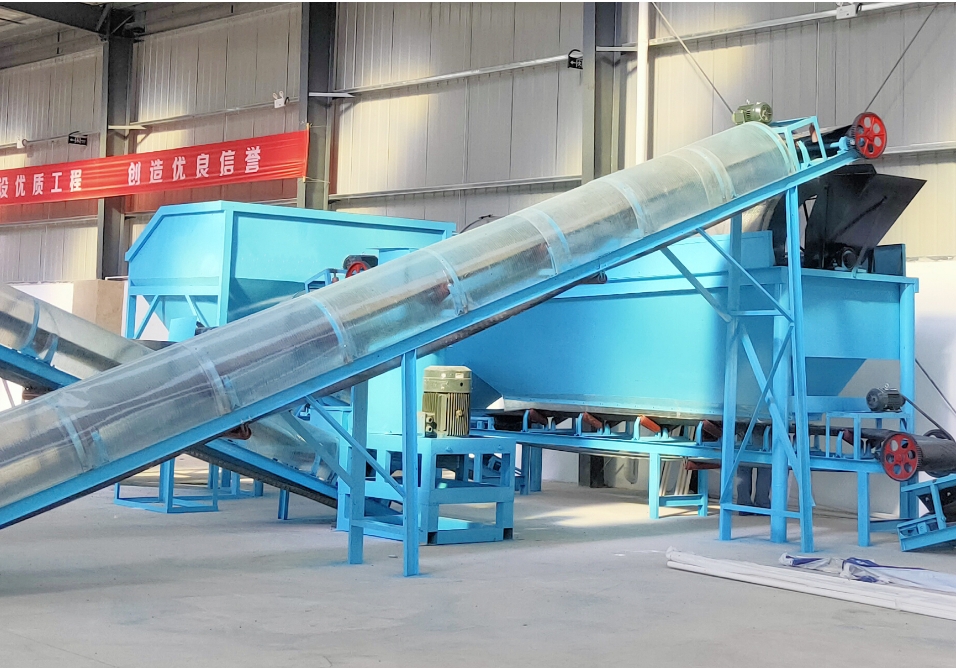

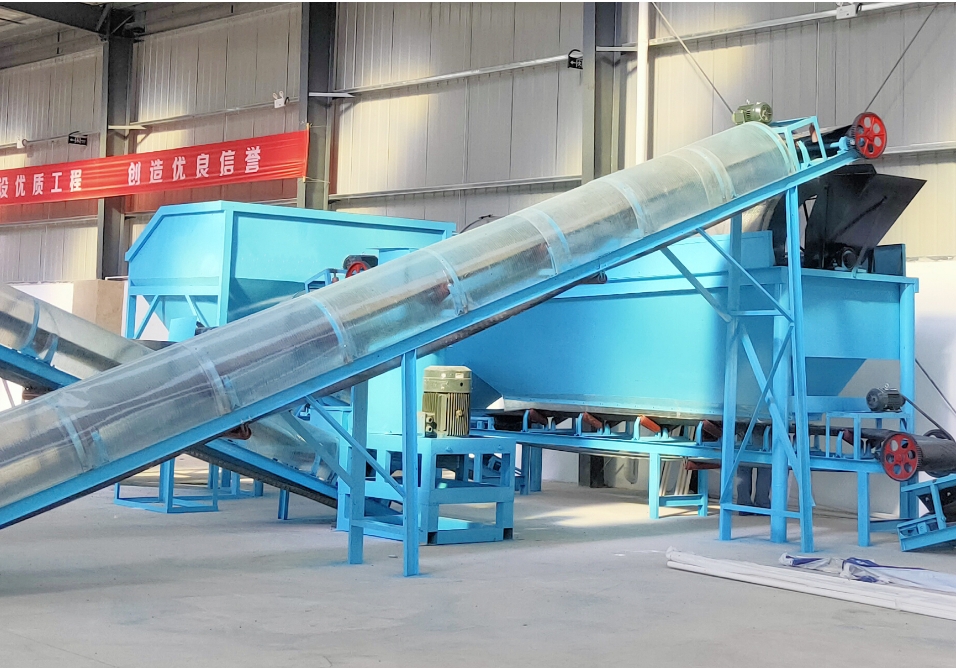

Waste organic fertilizer granulating production line includes

fermentation machine, crusher, mixer, granulator machine, dryer,

cooler, screening machine, packing machine,belt conveyor and other

accessories,etc.

Fermentation process

The fermentation of bio-organic raw materials plays quite a basic

role in the whole production.Sufficient fermentation lays a solid

foundation for the quality of the end products. Groove type compost

turner can thoroughly compost and turn high-stacked fermentation

materials with large production capacity.Self-propelled compost

turner can work freely outside or inside the factory,greatly

increasing the speed of aerobic fermentation.It is natural compost

at the open place or in the compost tank with ceil; normally the

compost fertilizer need about 5-8 days to ferment, and become purer

organism.

1.Crushing process

Our semi-wet material crusher with high-speed rotating blade is a

new type and high-efficiency single reversible crusher,and has

strong adaptability to high water-content organic matter.Semi-wet

material crusher is widely used in the organic fertilizer producing

process and it performs well in crushing chicken manure, sludge and

other wet materials. Crushing fertilizer raw material into small

size that can go further process for granulating.

This fertilizer crusher greatly shortens the production cycle of

organic fertilizer,and saves production cost.

2.Mixing Process

After crushing,auxiliary materials are added into the materials

according to the formula and mixed in the mixer.We provide

single-shaft mixer and double-shaft mixer for you to mix the

materials evenly.

3.Granulating Process

This machine can help reduce the energy that is wasted in the

drying process,because granules can be immediately screened after

the granulation process.The purity of the organic fertilizer

granules can reach as high as 100%,which makes the pure organic

fertilizer production come true and meet the needs of the customers

directly.This machine is featured with low energy consumption,low

production expenses and high production quantity and is considered

as your best choice for pure organic fertilizer production.

4.Drying Process

Rotary drum drying machine is mainly used for drying the fertilizer

with a certain degree of humidity and particle size. Materials are

transported to the drum by belt conveyor.Rotary dryer is suitable

for large,medium,and small farms.Different sources of heat are

applied,such as coal gas producer, directly/indirectly heated

stove,etc.according to different drying requirements of

5.Cooling Process

Rotary drum cooler is used for cooling fertilizers to make

fertilizer particles stronger.

6.Screening Process

We provide high-quality and good-performance rotary drum screening

machine which is used for separating the returned materials and the

finished products.The returned materials will go back to fertilizer

crusher for further process,while the finished products are

conveyed to fertilizer coating machine,or directly transported to

automatic fertilizer packager.

7.Packing Process

The finished products enter into the packing machine through the

belt conveyor.The fertilizer packaging machine packages finished

products quantitatively and automatically.

Services of waste organic fertilizer granulating production line

Pre-sale Service

1.Offering overall technology and business consultation services;

2.Proposing the most suitable scheme and equipment for our

customer;

3.Designing and producting machine according to the special demands

of clients;

After-sales Service

1.Carefully checking machine in every working procedure, quality

comes first;

2.Assisting our clients for foundation construction of equipments;

3.Dispatching engineers to install and debug equipments,training

the first-line operators on site;

4.Regularly visit clients to solve production problems and

providing our technology support.

We have more than 15 years experience, support you best before and

after sales service.Quality is first and top Pursuit of our

company.