| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Silicone Products Making Machine |

|---|---|

| Brand Name: | Fulund |

| Model Number: | FLD-B09-1 |

| Certification: | CE |

| Place of Origin: | CHINA |

| MOQ: | 1 |

| Price: | competitive |

| Payment Terms: | T/T, Western Union, MoneyGram |

| Supply Ability: | 100PCS/MONTH |

| Delivery Time: | 7days |

| Packaging Details: | WOODEN CASE |

| NAME: | Flat vulcanizing machine |

| Automatic grade: | Semi-Automatic, Automatic, manual |

| Core Components: | PLC |

| Dimension(L*W*H): | 1400*2000*1600MM |

| Voltage: | AC380V±5% |

| Power (kW): | 12 |

| Keyword 1: | silicone plate vulcanizing hydraulic press |

| Keyword 2: | vacuum rubber mould vulcanizer machine |

| Keyword 3: | vacuum silicone plate vulcanizing hydraulic press |

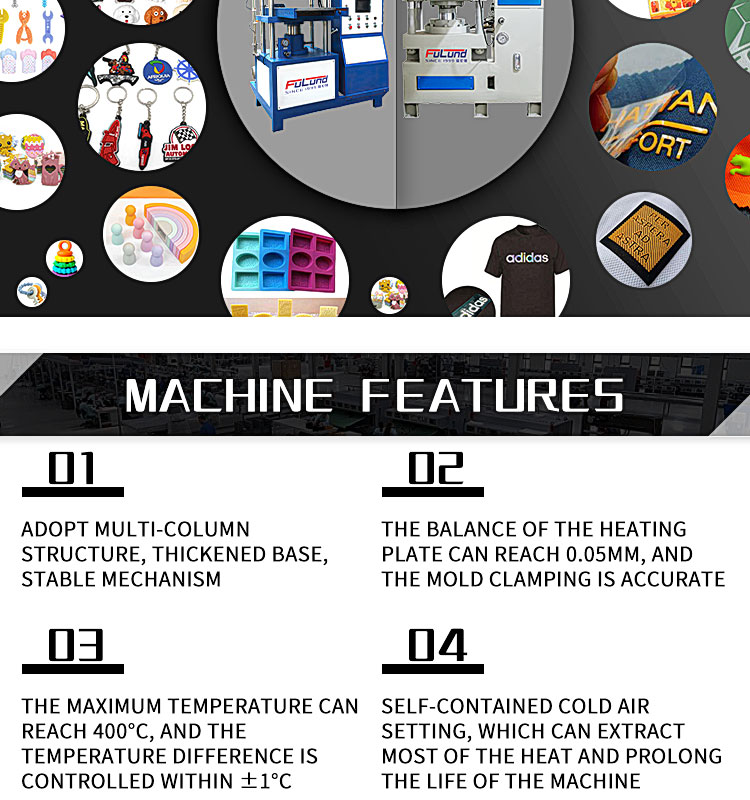

Vacuum Rubber Mould Vulcanizer Machine Vacuum Silicone Plate Vulcanizing Hydraulic Press

Fulund has a long history since its establishment in 1999. Due to the needs of development, the original brand (TYL) expanded the new brand Fulund in 2022 . Fulund has customers all over the world,such as international brands shoe manufacturer.

Details of the rubber vulcanizer

1.Material of steel plate:

We use hight quality carbon steel Q-235,more thicker than other supplier,after shot blasting ,smooth, it is strong enough than common steel

2.Weldment of frame : world technique

Welded together as a whole part,Stewing fire treatment after weldment.

(Carbon dioxide gas shielded welding,alloyed welding wire).submerged arc welding, VSR treatment after weldment.

3.Piston:

the material of plunger is Chilled cast iron, after polishing,grinding treatment and resist compression test,make the surface smooth,anti-abrasion,durable.

4.Heating way&precision temperature control:

Steam ,oil or Electric (We use high quality hot platen and heating pipe to keep heating stability and uniformity) range of temperature:0-300 °C (can be adjustment if you need 400 °C ,we can do it )

Plate temperature tolerance: ±0.1°C (very precise)other factory just is ±3°C

Also we can produce the machine with water cooling system.

5.Hydraulic system: (PLC control)

the professional hydraulic components, stable and reliable and quality .Pressure sensor control system pressure and never off pressure.

| Model | 30T | 40T | 50(63)T |

| Temperature regulation | At room temperature ~ 300 | At room temperature ~ 300 | At room temperature ~ 300 |

| normal temperature-200 degrees heating speed | about15min | about15min | about15min |

| Temperature precision | automatic/±2°C | automatic/±2°C | automatic/±2°C |

| Machine operation | control Circuit | control Circuit | PLC touch-screen |

| Drive way | hydraulic | hydraulic | hydraulic |

| pressure | 10-20Mpa | 10-20Mpa | 10-20Mpa |

| power supply | AC380V ± 5%50/60Hz | AC380V ± 5%50/60Hz | AC380V ± 5%50/60Hz |

| Power: | 12KW | 15KW | 18KW |

| Motor Power | 4KW | 4KW | 5.5KW |

| Heating plate distance | 200MM | 200MM | 200MM |

| Oil cylinder stroke | 200MM | 200MM | 200MM |

| Movement mode of skateboard | Automatic | Automatic | Automatic |

| Speed of rise and fall | ≥15mm/s | ≥15mm/s | ≥25mm/s |

| Pressure regulation mode | Pressure relay | Pressure relay | Digital modulation |

| Hot pressing time | 0.1s to 999s | 0.1s to 999s | 0.1s to 999s |

| Maximum pressure | 300KN | 400KN | 500(630)KN |

| Sliding plate area | 440 * 500MM | 440 * 500MM | 460 * 550MM |

| Heating plate area | 400 × 400MM | 400 * 400MM | 400 * 450MM |

| host volume | 1400 × 2000 × 1600MM | 1400 × 2000 × 1700MM | 1500 × 2000 × 1800MM |

| weight | 1200KG | 1350KG | 1500KG |

|

|