| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | High Temperature Alloy |

|---|---|

| Brand Name: | CJ |

| Place of Origin: | China |

| MOQ: | 100kg. We also can accept sample order. |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 10,000,000 tons/year |

| Delivery Time: | Fast delievery in7-10 days,up to order quantity |

| Packaging Details: | Industry standard packaging or according to client's requirement |

| Item Name: | 2205 Stainless Steel Strip |

| Material: | 2205 |

| Application: | It is widely used in high temperature applications, medical devices, building materials, chemistry, food industry, agriculture, ship components. It also applies to food, beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolt |

| MOQ: | 100kg. We can accept sample order |

| Shipment time: | Within 15-20 workdays after receiving deposit or L/C |

| Thickness tolerance: | ±0.01mm |

| Company Info. |

| Wuxi Chengjiu Metal Products Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

DIN 2507 Stainless Steel Strip Spring 19mm Flat Used In Food Vessel

You'll find strip steel used in appliances like refrigerators, washers, and dryers. The unique properties of strip steel have also made it a popular material for building and construction materials.

Product Name stainless steel strip

| Material | Surface Treatment | Thickness | width |

| 201 | BA | 0.15-0.8mm | 10-800mm |

| 202 | BA | 0.15-0.8mm | 10-800mm |

| 304 | BA | 0.025-0.8mm | 10-800mm |

| 304 | CSP(1/2H,3/4H,H) | 0.08-1.0mm | 10-690mm |

| 301 | CSP(1/2H,3/4H,H,EH) | 0.08-1.0mm | 10-690mm |

| 309S | 2B | 0.08-2.0 | 10-690mm |

| 310S | 2B | 0.08-2.0 | 10-690mm |

| 430 | BA | 0.15-0.8mm | 10-800mm |

| 430 | 1D | 0.15-0.8mm | 10-690mm |

| 430 | 2D | 0.15-0.8mm | 10-690mm |

| 430 | H | 0.08-1.0mm | 10-690mm |

| 409 | HD | 0.15-0.8mm | 10-690mm |

2.Chemical composition and mechanical

200 series:

| level | Chemical composition | Mechanical properties | |||||||||||

| C | Si | Mn | P | S | Ni | Cr | N | Cu | Y.S | T.S. | ELOG. | HRB | |

| % | % | % | % | % | % | % | % | % | N/mm2 | N/mm2 | % | ||

| 201(1% Nickel) | ≤ 0.15 | ≤ 1.00 | 8~11 | ≤ 0.060 | ≤ 0.030 | 0.9~1.5 | 15~17 | ≤ 0.25 | 1.5~2 | ≥ 310 | ≥ 655 | ≥ 35 | ≤ 105 |

| 202(4% Nickel) | ≤ 0.15 | ≤ 1.00 | 6~9 | ≤ 0.060 | ≤ 0.030 | 3.5~5 | 15~17 | ≤ 0.25 | 1.5~2 | ≥ 260 | ≥ 620 | ≥ 40 | ≤ 100 |

300 series:

| level | Chemical composition | Mechanical properties | ||||||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | Y.S | T.S. | ELOG. | HRB | |

| % | % | % | % | % | % | % | % | N/mm2 | N/mm2 | % | ||

| 304 | ≤ 0.08 | ≤ 0.75 | ≤ 2 | ≤ 0.045 | ≤ 0.03 | 8~10 | 18~20 | ≥ 205 | ≥ 520 | ≥ 40 | ≤ 90 | |

| 301 | ≤ 0.15 | ≤ 1.00 | ≤ 2 | ≤ 0.045 | ≤ 0.03 | 6~8 | 16~18 | ≥ 205 | ≥ 515 | ≥ 40 | ≤ 95 | |

| 316 | ≤ 0.08 | ≤ 1.00 | ≤ 2 | ≤ 0.045 | ≤ 0.03 | 10~14 | 16~18 | 2~3 | ≥ 205 | ≥ 515 | ≥ 40 | ≤ 90 |

| 316L | ≤ 0.03 | ≤ 1.00 | ≤ 2 | ≤ 0.045 | ≤ 0.03 | 12~15 | 16~18 | 2~3 | ≥ 170 | ≥ 480 | ≥ 40 | ≤ 95 |

400 series:

| level | Chemical composition | Mechanical properties | |||||||||||

| C | Si | Mn | P | S | Ni | Cr | N | Cu | Y.S | T.S. | ELOG. | HRB | |

| % | % | % | % | % | % | % | % | % | N/mm2 | N/mm2 | % | ||

| 430 | ≤ 0.12 | ≤ 1.00 | ≤ 1 | ≤ 0.040 | ≤ 0.030 | 16~18 | ≥ 450 | ≥ 205 | ≥ 22 | ≤ 88 | |||

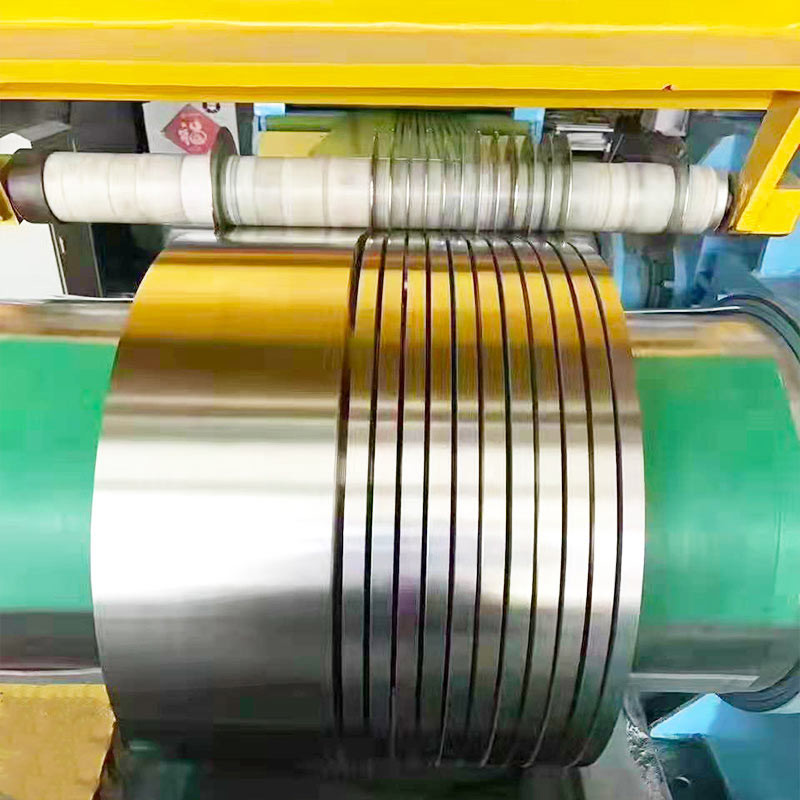

3.Product Show

|