| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Used Camshaft |

|---|---|

| Brand Name: | Caterpillar |

| Model Number: | C13 |

| Place of Origin: | USA |

| Price: | Negotiated |

| Payment Terms: | D/P, T/T |

| Supply Ability: | 50 pieces |

| Delivery Time: | 5 - 8 work days |

| Packaging Details: | Neutral Package or Fumigation Free |

| Excavator model: | E349F |

| Engine model: | C13 |

| Part number: | 224 - 1275 |

| Condition: | Used |

| Size: | Standard |

| Color: | Same as pictures |

| Material: | Steel |

| Type: | Diesel Engine |

| Company Info. |

| Beijing Silk Road Enterprise Management Services Co.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

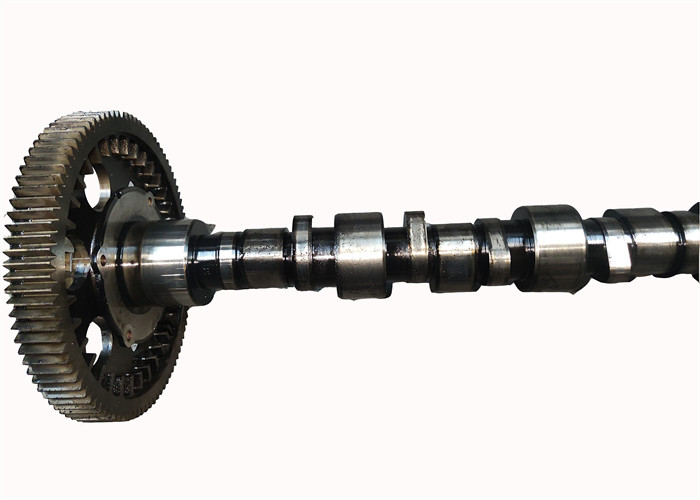

C13 Used Camshaft For Excavator E349D E349F 224 - 1275 Electric

Specification

| Item name | Engine Camshaft |

| Geer quantity | 100 |

| Application | Engineering Machinery Engine |

| Camshaft code | 224 - 1275 |

| Geer number | 224 - 3247 |

| Engine type | Diesel |

| Injection | Electric injection |

| Size | Standard |

Description

How does Camshaft work?

The main objective of the camshaft is to open the suction valve and

exhaust valve at the appropriate time. The crankshaft drives to

this shaft. It is linked with the crankshaft through a belt or

meshing gears.

The movement of the camshaft is slower than the crankshaft. It completes one revolution after two revolutions of the crankshaft. In a four-stroke engine, a camshaft works in the following way:

As the piston moves from TDC to BDC (downward), it transfers its motion to the crankshaft.

The crank receives piston motion and transforms this motion into

rotary motion, and starts rotating.

The crankshaft is connected with the camshaft through gear or belt.

As the crankshaft transfers its rotary motion to the camshaft, the

camshaft converts this rotary motion into reciprocating motion and

presses the inlet valve and opens it.

As the valve opens, the fuel starts to enter the combustion

chamber.

After suction and compression strokes, the combusted air-fuel

mixture expands in the chamber, which forces the piston to move

downward.

During the downward motion of the piston, again, the crankshaft

receives motion and moves the camshaft.

As the cam of the exhaust valve receives this motion, it presses

the exhaust valve and opens it, which allows exhaust gases to move

out of the combustion chamber.

Camshaft Construction Material

The solid material is most commonly used for the manufacturing of

the camshaft. This is because such camshafts provide great

rigidity. Cast iron is also used for the manufacturing of camshafts

because cast iron delivers more strength.

The camshafts made of the chilled iron process can provide excellent wear resistance because the chilling method hardens the material. Different materials mix with iron to generate the most appropriate features for their applications.

Some industries also utilize billets when less production and excellent quality are needed. But this process demands high time and cost compared to other processes. These shafts manufacture through machining, casting or forging on milling and lathe machines. They are manufactured by forging, casting and machined on lathes and milling machines.

|