| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Beryllium Copper Strip |

|---|---|

| Brand Name: | CUBERYLLIUM® |

| Model Number: | Alloy 25 |

| Certification: | ISO,SGS |

| Place of Origin: | China |

| MOQ: | 50 |

| Price: | 30USD |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 200T/Month |

| Delivery Time: | 10~15days |

| Packaging Details: | Coil+plywood case |

| Name: | Alloy 25 Beryllium Bronze Coil |

| Max Coil Wt.: | 2T |

| Thinnest Thick.: | 0.254mm |

| Width: | 8.2mm |

| Standard: | ASTM B194, SAE J463, J461 |

| Safe Handling: | No special health risk. |

| Machining Property: | Good |

| Surface: | Bright/Polished |

| Flatness: | Good |

| Temper: | 1/2H |

| Coil Weight: | Material can be coiled in apporximately 12kg coils. |

| Company Info. |

| Hangzhou Cuberyllium Metal Technology Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Alloy 25 Beryllium Bronze Coil TD02 Berryllium Copper 0.254MM*8.2MM Coil

Product Normal Description:

| Product Name | Beryllium copper Alloy 25 strips |

| Grade | C17200 |

| End Product Form | Strips/Tape |

| Standard | ASTM B194 |

| State of product | Half Hard(TD02) |

| Specification | Thickness: 0.254mm Width: 8.2mm |

| Application | Industrial |

Introduction of Alloy 25 Beryllium Bronze Alloy:

Beryllium Copper is an alloy that is machinable, weldable and ductile. Alloy 25 copper rod is highly resistant to abrasive wear, plastic decomposition products, galling and to non-oxidizing acids like carbonic acid and hydrochloric acid. Beryllium Copper C17200 bar is the strongest and the most widely used of all the Beryllium Copper materials. Beryllium Copper C172 round bars consists of 1.8 - 2% Beryllium. In Europe, Beryllium Copper C172 Bar is known as CuBe2 Bar. C17200 beryllium copper round bar is used in many application areas such as aerospace bushings, drilling tool components in the oil and gas industry, cavities and cores in injection mold tooling and bushings and plates in heavy equipment wear.

Industrial Uses for Alloy 25 Beryllium Bronze Alloy:

Because of their high thermal conductivity, excellent hardness, and

high-temperature strength, copper alloys are frequently used for

applications requiring high electrical conductivity and superior

mechanical strength.

It is its strength that makes this alloy a great choice when you

require wear and corrosion resistance and excellent bearing

properties.

Cuberyllium's Available Forms for Alloy 25 Beryllium Bronze Alloy:

Available forms are beryllium copper welding rod, beryllium copper wire, beryllium copper bar, beryllium copper bushings, beryllium copper coil, beryllium copper drill bits, beryllium copper electrodes, beryllium copper flat bar, beryllium copper fasteners, beryllium copper gasket, beryllium copper ingot, beryllium copper nuts, beryllium copper round bar, beryllium copper sheet

Chemical Composition of Alloy 25 Beryllium Bronze Alloy:

| Be | 1.80-2.00% |

| Co+Ni | 0.20% Min. |

| Co+Ni+Fe | 0.60% Max. |

| Others | 0.50% Max. |

| Cu | Balance |

| Note | Cu+Be+Co+Ni+Fe:99.50% Min |

Product Photo of Alloy 25 Beryllium Bronze Coils:

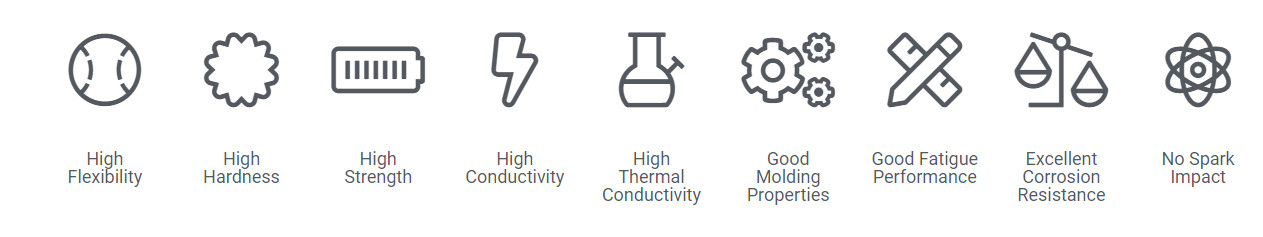

Excellent Properties of CuBe2 Copper Alloys:

Tensile Strength

Beryllium Copper can attain the tensile strength. of 1500N/ mm2

through precipitation hardening and can withstand very high bending

stress.

Corrosion Resistance

Beryllium Copper has excellent corrosion resistance, nearly the

same as Nickel Silver.

Electrical Conductivity

The electrical conductivity of beryllium copper ranges from 20 to

70 %IACS, depending on alloy and temper.

Age Hardenable Tempers

This term means the material can be strengthened by simple heat

treatment after stamping or forming. The strength level will be

roughly doubled by optimum heat treatment.

ASTM Designation Description Name

TB00 Annealed A

TD01 Quarter Hard 1/4 H

TD02 Half Hard 1/2 H

TD04 Hard H

|