| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Kiln Refractory Brick |

|---|---|

| Brand Name: | CRE |

| Model Number: | SX |

| Certification: | ISO9001, ISO14001, ISO50001, ISO45001 |

| Place of Origin: | CHINA |

| MOQ: | 10MT or 1*20GP |

| Price: | USD 600-2000/MT |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10000 Ton/Tons per Month Magnesium Aluminum Spinel Bricks For Cement Rotary Kiln |

| Delivery Time: | NEGOTIABLE |

| Packaging Details: | Magnesium Aluminum Spinel Bricks For Cement Rotary Kiln will be packed by Pallet+Paper or Steel angle bead+Paper board +Plastic or Steel belt +Plastic film or according to customer's requirements. |

| ORIGIN: | JIANGSU,CHINA |

| HS Code: | 85149090 |

| CrO Content (%): | 0-3.0 |

| MgO Content (%): | ≥83 |

| Thermal conductivity(w/mk): | ≥15 |

| Refractoriness (Degree): | 1770°< Refractoriness< 2000° |

| Working temperature: | ≥1800℃ |

| Raw material: | High purity magnesia and fused magnesia,fused hercynite |

| Company Info. |

| yixing xinwei leeshing refractory materials co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Best price refractory magnesia alumina spinel bricks for cement rotary kiln transition zone

Magnesium aluminum spinel brick is to improve the thermal stability of magnesium bricks, adding alumina in the ingredients and the production of magnesium aluminum spinel as the main mineral magnesium brick. Magnesium aluminum spinel brick is a low calcium content of high quality magnesia and industrial alumina powder as the main raw material, by high pressure forming, high temperature firing. Anti-quenching and emergency hot, good for iron oxides, alkaline slag and other solvents have good resistance to erosion.

Advantages

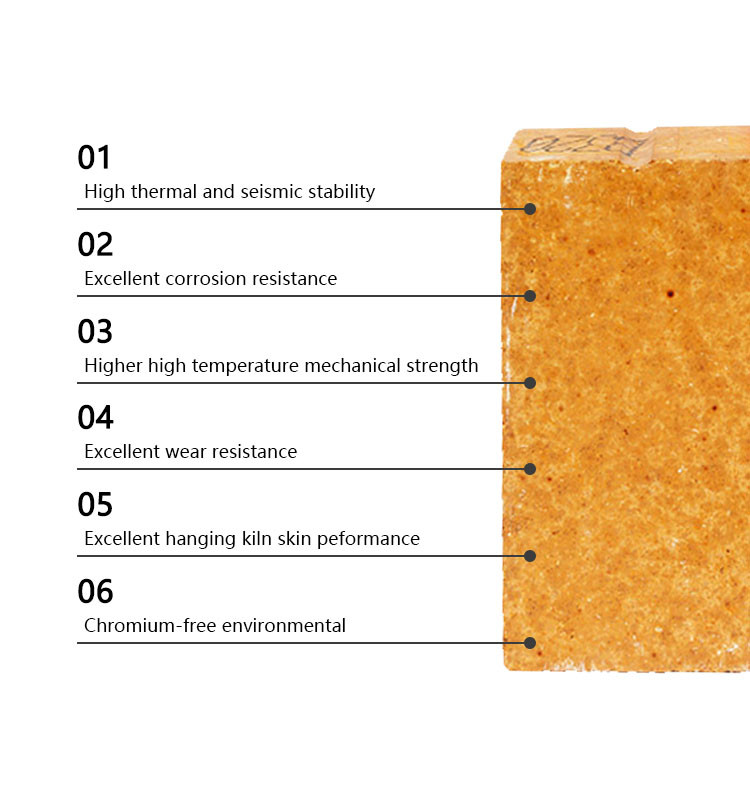

Good thermal stability, in the course of the use of clinker with

the reaction, and then in the brick surface to form a thin layer of

calcium aluminate protective layer, so that the liquid is not easy

to penetrate.

its anti-peeling performance is better than the direct combination

of magnesia-chrome brick. The life of the cooling zone and the

transition zone of the kiln can be directly combined with

magnesia-chrome brick. However, in the corrosion resistance is

slightly inferior to the direct combination of magnesia-chrome

brick.

Sintered spinel brick easy to hydrate, resulting in a larger

coefficient, the kiln body temperature than the direct combination

of magnesium chrome brick when the high. In the use of attention to

these issues.

Material name Item | Silicon Brick | Silicon Mo red brick | Magnesium iron spinel brick | |||||||

SX- 1680T | SX- 1650T | SX- 1550T | SX- Ⅰ | SX- Ⅱ | SX- H | SX-MFe -80 | SX-MFe -85 | SX-MFe -90 | ||

(%) Chemical composition | AL2O3 (%)≥ | 65 | 65 | 63 | 67 | 65 | 69 | |||

| SiO2 +SiC≥ | 30 | 30 | 31 | 30 | 30 | 25 | ||||

| SiO2 (%)≤ | 2.0 | 1.0 | 1.5 | |||||||

| MgO | -- | -- | -- | 80 | 85 | 90 | ||||

| Fe2O3 (%)≤ | 7.5 | 7.5 | 4.5 | |||||||

Apparent porosity(℃) | 1790 | 1790 | 1790 | |||||||

Bulk density(g/cm3)≥ | 2.66 | 2.65 | 2.60 | 2.7 | 2.7 | 2.75 | 2.90 | 3.00 | 2.85 | |

Apparent porosity(%)≤ | 17 | 17 | 17 | 17 | 17 | 16 | ||||

Cold crushing strength(Mpa)≥ | 90 | 95 | 90 | 100 | 90 | 100 | 45 | 50 | 50 | |

T0.6 (℃)≥ Refractoriness under load | 1680 | 1650 | 1550 | 1650 | 1630 | 1660 | 1550 | 1600 | 1650 | |

Thermal shock resistances (1100℃water, cycle ) | 12 | 10 | 10 | 15 | 12 | 18 | 80 | 100 | 80 | |

Normal Temp(cm3)≤ | 8.5 | 8.2 | - | |||||||

(1000℃)(W/m·k)≤ Thermal conductivity coefficient | 2.0 | 2.3 | 2.4 | 1.7 | 1.7 | 1.7 | 2.6 | 2.6 | 2.6 | |

(1400℃)(%) Thermal expansion | 1.6 | 1.6 | 1.7 | |||||||

Packing and shipping

1 tray + plastic film + fixed band

2 pallets: 1*1m,0.93*0.93m

3 tray weight: 1.6~2.0ton

4 packaging according to customer service requirements

|