| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Alumina Silica Refractory Brick |

|---|---|

| Brand Name: | CRE |

| Model Number: | XCL |

| Certification: | ISO9001, ISO14001,ISO50001,ISO45001 |

| Place of Origin: | JIANGSU,CHINA |

| MOQ: | 1*20GP |

| Price: | FOB Shanghai USD150-1500/MT |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10.000MT Per month |

| Delivery Time: | To be negotiated |

| Packaging Details: | 1.On wooden pallets with plastic cover 2. According to customer's demands for Customized Processing Fused Semi-rebonded Magnesia Chrome Bricks |

| Al2O3 Content (%): | 30% 35% 38% 42% |

| SiO2 Content (%): | 55-65% |

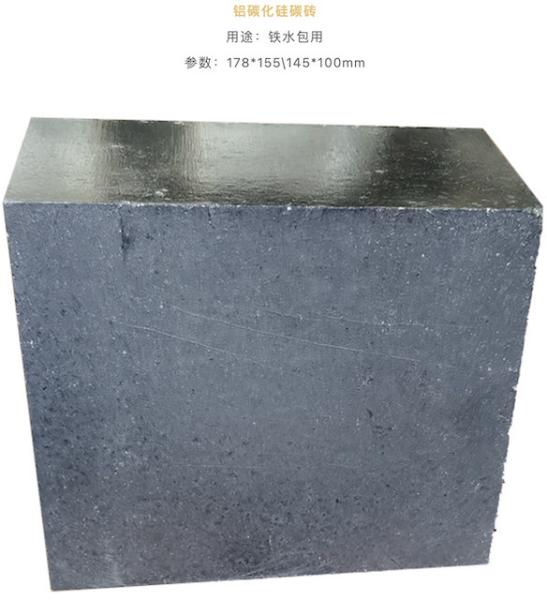

| Raw material: | Silicon Carbide Powder |

| Application: | Cement rotary kiln,glass kiln regenerative chamber etc |

| Color: | Black and green |

| Processing: | Bending, Welding, Punching, Decoiling, Cutting, Moulding |

| Cold crushing strength: | 50-55 Mpa |

| product name: | Alumina Silica Refractory Brick |

| Company Info. |

| yixing xinwei leeshing refractory materials co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Factory Direct Price High Porosity Heat Insulation Refractory Light Weight alumina silica refractory Brick

Lightweight clay brick is made of high purity fire clay, by adding combustible, gas evolution method, or foam method.Lightweight clay brick is a kind of porous material with Al2O3 content 30-46%. Its refractoriness is 1580-1750 °C, refractoriness under load is 1250-1450 °C, with good thermal resistance and strong ability to resistant acid slag.The bulk density is 0.75-1.2g/cm3, crushing strength is 2.0-5.9MPa, thermal conductivity is 0.221-0.442W/(m.K) (1350°C)

Application For Silica Brick:

Mainly used in the construction of regenerative chamber, chute,

combustion chamber, coking chamber, furnace roof etc. parts of the

coke ovens.

Also be used for coke oven of coking chamber and combustion chamber

partition, steel open hearth of regenerative chamber and sediment

chamber, soaking furnace, glass melting furnace, refractory silica

brick materials and ceramic firing kiln and kiln of the vault and

other supporting parts. Also used in hot blast stove of high

temperature bearing parts and acid open hearth furnace roof.

| Item/Grade | High Alumina Refractory Brick | |||

| SK-36 | SK-37 | SK-38 | SK-40 | |

| Al2o3% (≥) | 55 | 65 | 70 | 82 |

| Fe2o3% (≤) | 2.0 | 2.0 | 2.0 | 2.0 |

| Refractoriness (SK) | 36 | 37 | 38 | 40 |

Refractoriness under load, 0.2MPa, ℃ (≥) | 1450 | 1480 | 1530 | 1600 |

| Porosity(%) | 20-23 | 20-23 | 20-22 | 18-20 |

| Density(g/cm3) | 2.25-2.4 | 2.3-2.5 | 2.4-2.6 | 2.5-2.7 |

| Cold crushing strength, MPa (≥) | 45 | 50 | 60 | 70 |

The bricks are packed on wooden pallet with papers in each layer and PP film wrapped outside of the whole pallet.

|