| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Large Blow Molding Machine |

|---|---|

| Brand Name: | TONGDA |

| Model Number: | TDB-1200F |

| Certification: | CE, ISO9001 |

| Place of Origin: | JIANGSU, CHINA |

| MOQ: | 1SET |

| Price: | $60,000.00 - $70,000.00/Sets |

| Payment Terms: | T/T, L/C, D/P, West Union |

| Supply Ability: | 800sets/year extrusion blow molding machine |

| Delivery Time: | 50-60 working days |

| Packaging Details: | PE film, PE bag, Wooden Cases, Wooden Pallet, etc. for our extrusion blow molding machine and auxiliary equipments |

| Die Head: | Single Head Accumulator Type Die Head |

| Max. product volume: | 1200L |

| Output of HDPE: | 550KG/Hour |

| Platen distance: | 1100-2700 |

| Clamping force: | 1300KN |

| Platen size: | 1800×1600mm for our TDB-1200F extrusion blow moldinig machine |

500-1200L Water Tank Plastic Blow Molding Machine IBC Tank Extrusion Blow Moulding Machine

Product Description

Our TDB-1200F extrusion blow molding machine, which is specialized for manufacturing IBC tanks size from 500L to 1200L, this model extrusion blow molding machine we have single and double layer configuration to meet customer's different requirements.

We equip servo motors for hydraulic system & plasticizing on this model extrusion blow molding machine, which make it more energy saving.

Many customers are using our single layer and double layer TDB-1200F extrusion blow molding machine producing their IBC tanks, and leading the market.

Technical Parameters of our TDB-1200F Extrusion Blow Molding Machine

MODEL | Units | TDB-1200F | Remarks: we will customize the most suitable extrusion blow molding

machine for you according to your requirements |

Max. Product volume | L | 1200 | |

Output of HDPE | kg/h | 550 | |

Clamping force | kn | 1300 | |

Screw diameter | mm | 100*2 | |

Screw heating power | kw | 25*2 | |

Capacity of Accumulator head | L | 45 |

Product Details of our TDB-1200F Extrusion Blow Molding Machine

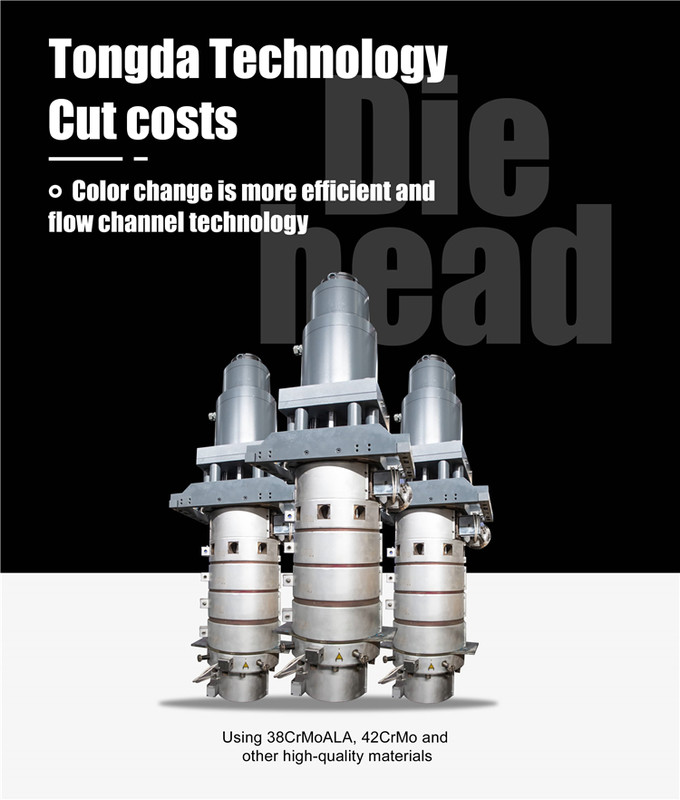

Our own R&D department designed designed the die head of our extrusion blow molding machines, the die head parts are all processed on machining centers and other processing equipments, and made the treatment in qulified centers. Then our assembling center assembled. So we can ensure the confidentiality of the core technology and the manufacturing precision, and at the same time facilitate the later debugging and maintenance.

Company Information

Suzhou Tongda Machinery is a professional manufacturer of extrusion blow molding machine with over 23 years experience. And we have won the NO. 1 in China domestic extrusion blow molding machine field for continuously 10 years.

We have sold more than 7,000sets machines to customers from more than 120 countries and regions, annual output of extrusion blow molding machine is 800sets/year now.

In the recent 20 years, Suzhou Tongda Machinery Co., Ltd. has been focusing on the research, development and product application of extrusion blow molding machines. The factory covers an area of more than 80 acres of land and has more than 350 employees.

Warmly welcome new and old customers to visit, to guide.

Service Network

Our Machinery has been keeping good cooperative relationship with customers since our establishing.

The satisfaction of our customers are the pursuit of every member of Tongda,The only way we service in the competitive market is to help our customers to full fill their requirement.

FAQ

Advantages of TONGDA technical teams

|