| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Shutter Door Roll Forming Machine |

|---|---|

| Brand Name: | Sussman |

| Model Number: | SM-SD-045 |

| Certification: | CE,SGS,ISO |

| Place of Origin: | Wuxi,China |

| MOQ: | 1 set |

| Price: | negitable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 5 sets per month |

| Delivery Time: | 30-90 days |

| Packaging Details: | standard film |

| Main Power: | GCr15 Steel |

| Tile type: | Steel |

| Color: | As customer requirement |

| Control system: | PLC control system(brand as requirement) |

| Roller material: | 45# steel |

| Usage: | Roller Shutter Door |

| Power(w): | 7.5KW |

| Cutting: | Hydraulic Cutting |

| Company Info. |

| Sussman Machinery(Wuxi) Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

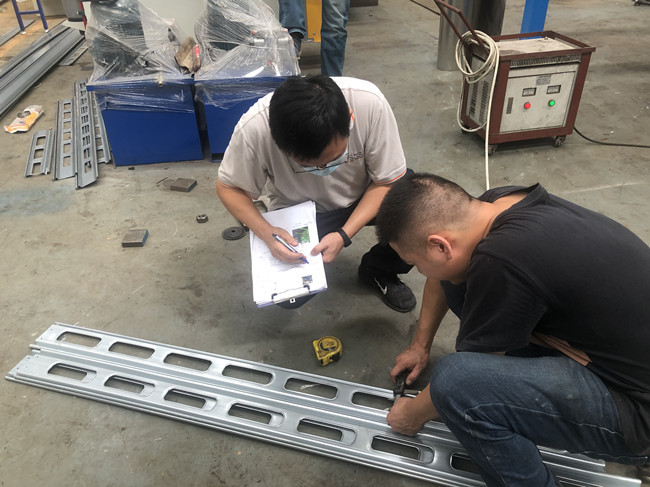

7.5KW Hydraulic Shutter Door Roll Forming Machine Punching Galvanized Metal

Roller shutter doors are produced by roller shutter door machine and are used for parking lot doors and home doors, storefront displays and garages, etc. They are very sturdy and are a sage. Therefore, roller blinds provide sufficient protection and security against theft and fire. If sufficient steel thickness is used, these doors will be stronger and will last longer

The technique data

1. 1. Materials to form shutter door. 0.7-1.2mm, Galvanized coils

2. 2. Forming steps: about 12 steps

3. 3. Material of rollers: GCr15 steel, precision-machined, high

frequency quenching HRC58-62, diameter of rollers: >¢150

4. 4. Material of main shaft : 45# high quality steel

(diameter>¢50)

5. 5. Chains’ material: 45# steel, high frequency quenching,

circular pitch:38.1; number of teeth: 13

6. 6. Cutting : hydraulic cutting; quenching HRC58-62

7. 7. Electronic control: PLC control (Delta)

8. 8. Dimension of machine: 6500mmX800mmX800mm, total line about 20

meters per min.

9. Drive system: chain drive, 5.5KW main motor power, working

speed:10-12m/minwithout the punching, if with punching, about 1-2

meters per min.

Working flow:

Decoiler—→Level device—→Main roll forming machine—→Hydraulic

punching—hydraulic cutting→ Run out table

Profile drawing

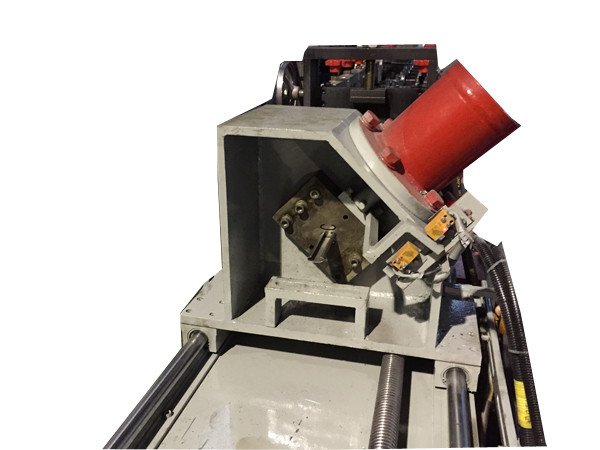

Machine Shows

Cutting:

(1) Cutting motion: The main machine stops and then cut automatically. After cutting, the main machine re-starts automatically.

(2) Material of blade: CR12mov with heat treatment

(3) Length measuring: Automatically

(4) The cutting thickness: 0.3- 0.8mm

(5) Hydraulic Station Power: 4 KW

|