| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Fiber Bed Mist Eliminator |

|---|---|

| Brand Name: | AHS |

| Model Number: | ZR-122 |

| Certification: | ISO9001 |

| Place of Origin: | China |

| MOQ: | 1 piece |

| Price: | Discuss again |

| Payment Terms: | T/T |

| Supply Ability: | 1000 pieces per week |

| Delivery Time: | 5-20 work days |

| Packaging Details: | carton and wooden box |

| Product Name: | Preservative Cylindrical Fiber Glass Fiber Bed Mist Eliminator |

| Key Words: | Fiber Glass Fiber Bed Mist Eliminator |

| Material: | PVC |

| Application: | Food Processing |

| Pressure Drop Loss: | 60 |

| Handling Gas Volume: | 1300 |

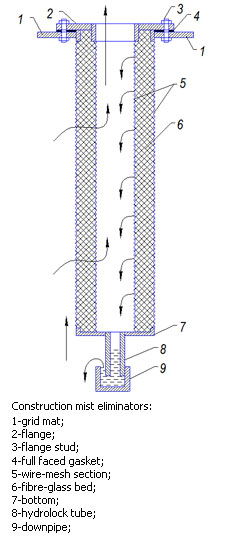

Candle fiber mist eliminators are composed of single or multiple demisting elements installed in a container or tank. When the gas containing mist particles passes through the fiber bed horizontally, the mist particles are captured by inertial collision, direct interception, and Brownian motion principles. Collected on a single fiber of the mist eliminator, and gradually condensed into large particles or liquid film, under the action of airflow driving force, passed through the fiber bed, and discharged from the bed along the inner surface of the bed under the action of gravity, Achieve the effect of trapping mist and purifying gas.

| Name | Conditional name | |||

| Low-speed high-efficiency | High-performance | High Speed | Mist eliminator | |

| Speed of filtration, m/s | 0,05 - 0,2 | 1,1 - 1,3 | 2 - 2,5 | 2,5 |

| Cleaning efficiency of particle,%: dc = 3 mcm dc = 1 ÷ 3 mcm dc ≤ 1 mcm | 100 | 100 | 100 | 100 |

| Resistance, kPa | 1 - 5,0 | 2 - 2,5 | 1,5 - 2,0 | 0,25 - 0,5 |

| Form of elements | Cylinder | Cylinder | Rectangular | Rectangular |

| Dimensions, mm: diameter (width) height | 216; 450; 605; | 650 | 470 | 470 |

| Thickness, mm | 50 - 60 | 50 - 60 | 25 - 30 | 25 - 30 |

| Fiber diameter, mcm | 6 - 15 | 18 - 20 | 10 - 30 | 30 - 80 |

1. Sulfuric acid manufacturing

2. Chemical processing

3. Chlorine and hydrogen production

4. Asphalt Roofing and Asphalt Storage

5. Food Processing

6. Metalworking

7. Pulp and paper

8. Textiles

Low-velocity mist eliminators are optimally equipped with a mix of glass fiber and a specific proportion of coarse and fine fibers. Coarse resistant fibers ensure uniform distribution of finer ones, increase the velocity of liquid discharge out of layer, giving the latter the mechanical strength and stability, and ensuring the operation of finer fibers throughout the layer. Usually the layers made of fibers 5-20 mcm in diameter and 88-92 % porosity are used . More often, the fibers 8 to 15 mcm in diameter with 50-60 mm layer thickness are used.

The basic material we use in filtering part is a special chemically-stable fiber glass FGM 145 in the form of multilayer needle-punched fabric resistant to concentrated and diluted acids. Besides, synthetic fibers of other types may be used depending on operating environment.

Hydraulic resistance: not more than 150 mm of water column.

Efficiency of mist eliminator of this type may be decreased in case the operating gas flow contains insoluble organic, metallic or mineral particles which may penetrate into the mist eliminator from the units installed before it. These may also be sulfate particles or chemically generated salts such as ammonium sulfate, ammonium nitrate, nitrosilic-sulfuric anhydride, nitrosilic pyrosulfite, etc.;

- in case the operating gas flow contains any amounts of HF or PH alkaline which cause the corrosion of fiber glass and may destroy the filtering part.

- in case the gas flow velocity is higher than 0.2 m/sec.

- in case the gas humidity is insignificant. The filtering part is efficient in humid state, and, in addition to the fiber thickness, the moisture creates “additional resistance” and Browning diffusion effect.

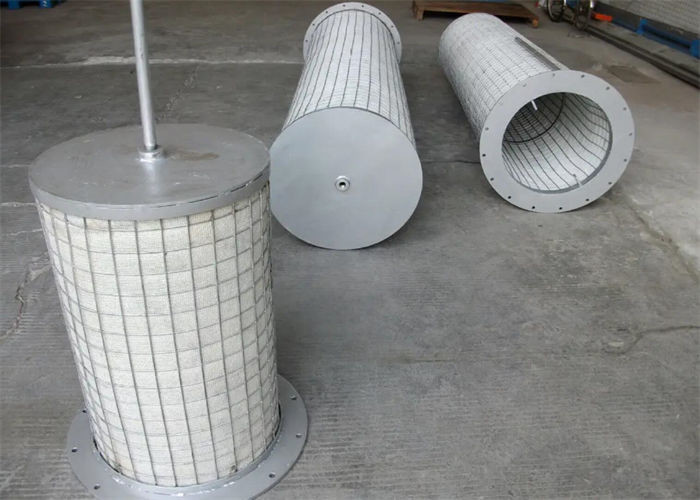

Anping County Hardware Mesh Products Co., Ltd. is located in Anping

County, Hebei Province, known as the "Hometown of Chinese Wire

Mesh". The company is a dedicated manufacturer of wire mesh

demisters. The company has more than 90 sets of knitted mesh

equipment.The wire mesh demister is the main product of our

company. Most of our employees are operation, maintenance, and

installation personnel with practical experience, who can provide

customers with the required engineering consultation and

installation of tank filtration. solution.Nearly 20 years of

experience in the production of mist eliminator mats, knitted wire

mesh, and other packaging materials.

We have ISO9001 certification and a strict quality control system

in the QC department of the enterprise.

We claim that all mist eliminator pads our customers receive are

qualified and perform perfectly. We have different specifications.

The filtration fineness can reach 3μm~5μm. In addition to standard

and popular sizes, we can also customize specific applications

according to customer needs.

During the company's development, through continuous on-the-spot

inspections, personal exchanges and cooperation with customers, and

comprehensive discounts and technical support, we have won strong

customer support and praise.

The company's performance has maintained an annual output value

growth rate of 30-40. Our employees pursue the policy of

"enterprising, truth-seeking, rigorous and united", continue to

develop and innovate, take technology as the core, and

wholeheartedly provide you with cost-effective products,

high-quality engineering design, and services.

|