| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Food Grade Metal Detector |

|---|---|

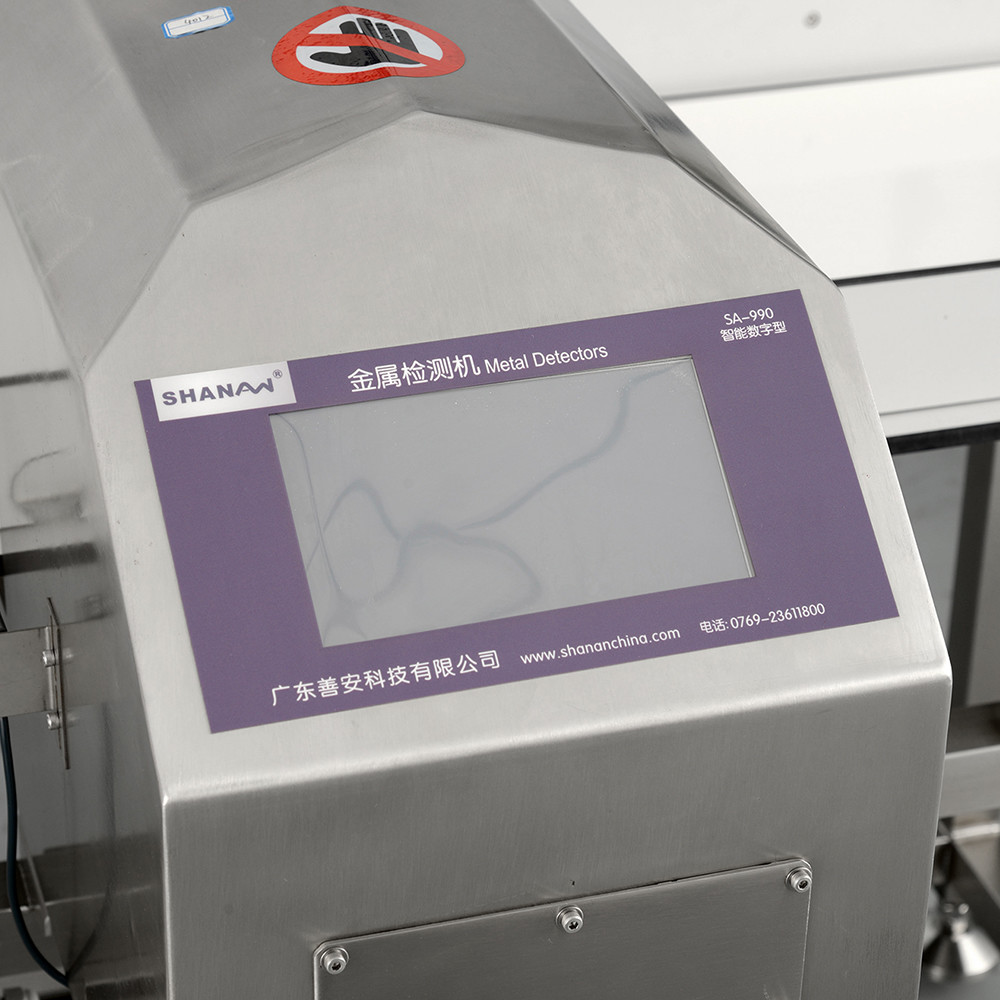

| Brand Name: | SHANAN |

| Model Number: | SA-990-6025 |

| Certification: | CE, ISO |

| Place of Origin: | CHINA |

| MOQ: | 1 set |

| Price: | negotiation |

| Payment Terms: | T/T |

| Delivery Time: | 15work days |

| Packaging Details: | Box |

| Supply Ability: | 100 set/month |

| Name: | food processing metal detectors for sale |

| Application: | metal detector for food factory |

| Oprate panel: | Touch screen |

| Type: | Conveyor Belt |

| Tunnel size: | W60xH25cm or customized |

| Belt speed: | 25m/min |

| Language: | English, Spanish |

| Sensitivity: | High Sensitivity, Fe≥0.8mm, Non-Fe≥1.2mm, Sus≥2.0mm, 0.8mm ferrous |

| Power supply: | AC110V/220V/380V 50/60Hz, 220V, 50-60Hz, 110v/220v/380v, 110V/60hz 220V/50hz food grade metal detector |

| load weight: | 50 kg |

| Service time: | lifelong |

| Warranty: | 2 Year |

| Company Info. |

| GUANGDONG SHANAN TECHNOLOGY CO.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

Application: food, pharmaceutical, chemical, rubber, ice, ice products, toys, eyewear, shoes, leather, knitting, printing and other industries to detect the metal impurities in the production process or raw materials, such as: iron, non-magnetic metal Items (silver, steel, aluminum, stainless steel and other non-ferrous metals can be detected), improve product safety factor and reduce hazards.

Dried Foods, Cereals & Grains

Products that are typically inspected in dried foods, cereals & grains include: coffee, tea, nuts, dried beans, dried fruits, herbs, cereals, wheat, rice, flour, sugar, barley, quinoa and many more. This product is usually inspected in bulk or free-flowing form, either on a horizontal conveyor or a free fall gravity-fed detector, or could be inspected end of line when packaged. Physical contaminants can range from stones and bones to metal fragments, machine components, glass and plastic.

Advantages:

Advanced technology: the introduction of imported multi-detection technology, phase and comprehensive, product and automatic balance correction technology, the detection sensitivity and stability have been improved, the detection range is wider, especially for salt, high moisture content is difficult to detect The product has 2-3 times better detection sensitivity than similar products.

The core circuit adopts a single-chip high-performance FPGA hardware solution, using imported high-quality electronic components; [mainly selected by the United States Micro-chip, Analog Device, National Semiconductor, Wimma, Japan Hitachi, NEC, Sanyo and other companies to produce integrated circuits, capacitors, etc. Electronic components] After advanced processing technology and standardized inspection process, the product has high sensitivity and stable

Confectionery & Snack Foods

The Confectionery and Snack Food segment includes food products such as chocolates, candy bars, sweets, jellies, gums, hard and chew candies, through to snack foods such as potato chips, crisps, ready to eat nuts, trail mix, savory snacks, energy and granola bars.

Some challenges found within this sector include:

| SA series | 3008 | 3012 | 4008 | 4010 | 4012 | 4015 | 4020 | 4025 | |

| 50 Through width(MM) | 300 | 300 | 400 | 400 | 400 | 400 | 400 | 400 | |

| Passing height(MM) | 80 | 120 | 80 | 100 | 120 | 150 | 200 | 250 | |

| Belt width(MM) | 270 | 270 | 370 | 370 | 370 | 370 | 370 | 370 | |

| standard | FE(ΦMM) | 0.6 | 0.7 | 0.6 | 0.6 | 0.7 | 0.8 | 1 | 1.2 |

| Detection | NON-FE(ΦMM) | 0.8 | 1 | 0.8 | 1 | 1 | 1.2 | 1.5 | 1.8 |

| Sensitivity | SUS304(ΦMM) | 1 | 1.2 | 1 | 1.2 | 1.2 | 1.5 | 2 | 2.5 |

| conveyor length(MM) | 1200 | 1200 | 1500 | 1500 | 1500 | 1500 | 1500 | 1600 | |

| Belt height from the ground(MM) | 750±50 can customize | ||||||||

| protection level | IP67 | ||||||||

| Number of memory products | 100 kinds | ||||||||

| Operation method | Touch button input (touch optional) | ||||||||

| Conveyor belt material | food grade PVC belt(PU belt) | ||||||||

| Alarm mode | Alarm stop ,buzzer alarm or reject mechanism optional | ||||||||

| Belt speed | 28m/min | ||||||||

| Machine material | Carbon steel paint or stainless steel 304, fit for HACCP, GMP. CAS | ||||||||

| Machine weight | About 280KG | ||||||||

| Motor | Taiwan high-power motor can transport weight 1-15KG | ||||||||

| Power supply | AC220V±10% 50-60HZ (can be customized AC110V or 380V) other optional | ||||||||

| Using environment | Temperature:-18~50°C , relative temperature:30-90°C | ||||||||

https://www.youtube.com/channel/UCMCcyqdq_8qF7uqp0L82RQA

|