| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Drum Filling Machine |

|---|---|

| Brand Name: | ZT-PACK |

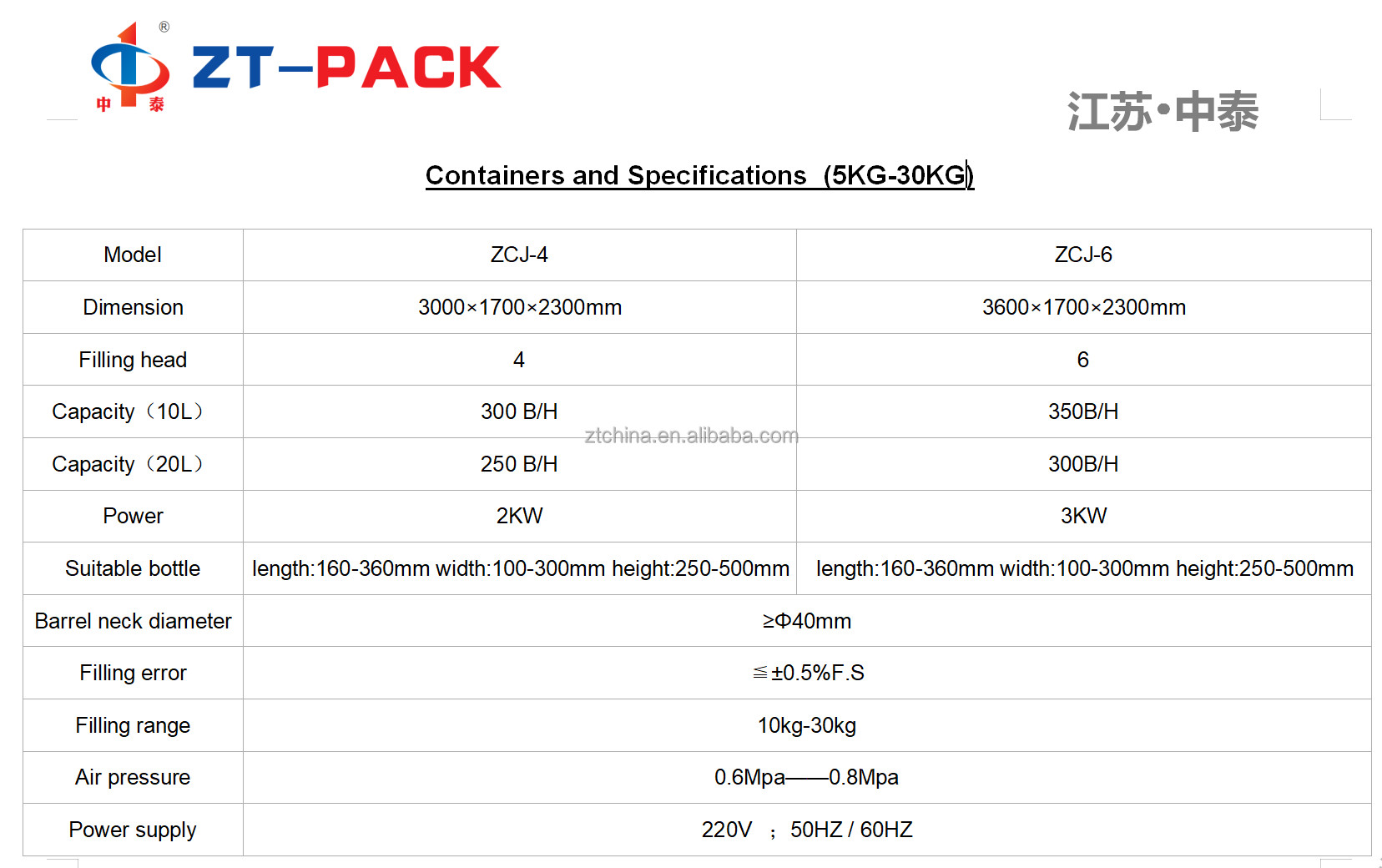

| Model Number: | ZCJ-4/6 |

| Certification: | CE,ISO,SGS,SABER |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 45sets per month |

| Delivery Time: | 30days |

| Packaging Details: | Wooden Case |

| Product Name: | Filling Machine |

| Application: | Chemical, Food, oil |

| Dimension(L*W*H): | 2200* 1300* 2350mm |

| Filling Material: | Oil, Other, chemical, Liquid |

| Capacity: | 200-600 drums/hour base on 20L |

| Machine material: | Food Grade SS304 / SS316 |

| Weight: | 1800 KG |

| Voltage: | 220V 50HZ |

| Key Selling Points: | Remote Control |

| Warranty: | 1 Year |

Automatic 5-30Kg Oil Filling Machine For Drum Barrel Gallons Chemical Liquid Packing Line

Description

Net weigh fillers are in ideal solution for ensuring each container

you fill has the same amount of product in it. They are the best

for liquids filled in bulk quantities, such as 5-gallon oil , or

products that have a very high value and thus need to be weighed

correctly to avoid losing profit.

This is weigh type filling machine for filling 5-30 KG Liquid .

Gravity filling system with weight scale under filling nozzle to

assure filling accuracy.

As well as pressure tank be used to make sure the capacity speed

faster.

Linear type machine, can be made with 4/6 filling nozzle for

different filling capacity.

It is ideal for filling big volume product like edible oil, wine,

lubrication, liquid fertilizer, chemicals etc.

Net weight filler is best suited for liquids to be filled in bulk

quantities e.g. 5 gallon pails, etc. or smaller quantity

products that have a very high manufactured value. Oftentimes there

are products that must be sold by weight for commercial reasons and

therefore this filling machine is the only choice. Examples of this

type of filler for bulk products include cleaning chemicals, enzyme

solutions, oils and other medium value products. High value

products filled by these machines include specialty adhesives and

paints, precious metals dissolved in acids, and other expensive

specialty chemicals.

The operation of this type of net weight drum filling machine is

simple. The product bulk supply is pumped into a holding tank above

a pneumatically operated valve. Cleaned containers are conveyed to

the filling machine through an SS slat conveyor, positioned on

individual load cell platform and tared. the valves open and real

time net weight information is monitored until the target weight is achieved. The valve simply shuts when the target

weight is achieved. Accuracy of fills is accomplished by various

“bulk and dribble” methods in the filling process so that overfills

are avoided.

The advantage of this bucket filling machine over others is that it

is sometimes the only practical (and legal) type of filling for a

limited range of applications and for large volume fills. It is

also very accurate and effectively provides its own quality control

assuming the scale is functioning properly. The disadvantage of

this type of filling machine is that it is very expensive per filling head. For these reasons, the use of this filling

technology is limited to the examples outlined above.

Suitable for fill:

|