| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | PP Strap Making Machine |

|---|---|

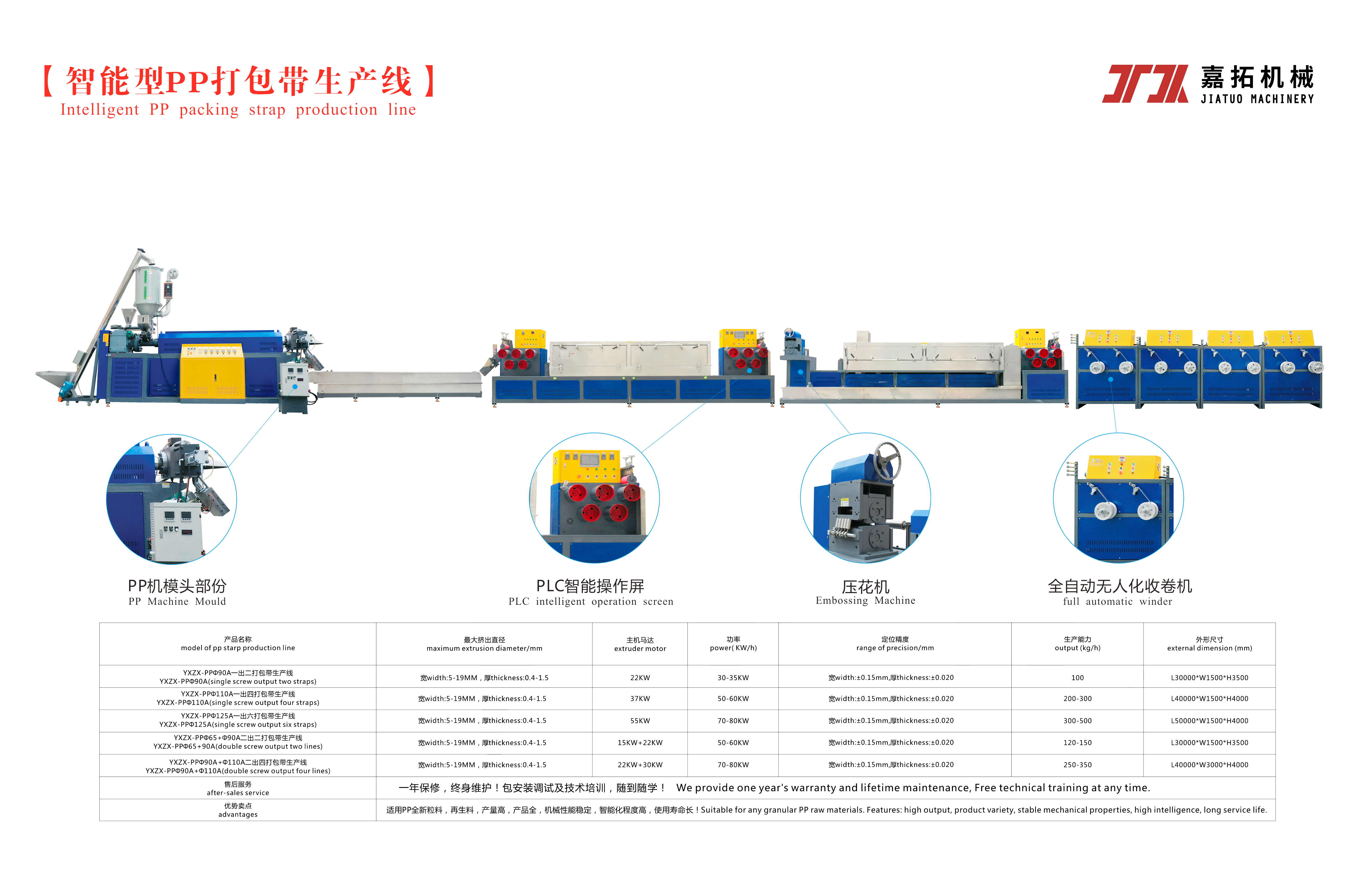

| Brand Name: | JIATUO |

| Model Number: | JT-PP |

| Certification: | CE, ISO |

| Place of Origin: | Shenzhen, China |

| MOQ: | 1 Set |

| Price: | Negotiable |

| Payment Terms: | L/C, D/A, T/T, Western Union, MoneyGram |

| Delivery Time: | 50~55 working days |

| Packaging Details: | plastic film or other standard package for sea shipping |

| Product type: | PP Strap Making Machine |

| Raw material: | PP |

| Screw design: | Single-screw,Double-screw,single or double |

| Processing type: | Extruding Machine |

| Application: | Packaging Strap |

| Temperature controller: | Omron for PET strap making machine |

| Twin Screw Type: | Co-rotating Parallel Twin-screw |

| Driven Type: | Electric |

| Automation: | Automatic |

| Warranty: | 1 Year |

| Company Info. |

| SHENZHEN JIATUO PLASTIC MACHINERY CO.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

Plastic PP Strap Band Extrusion Line Manufacturing Machine Plastic Packaging Machine

DESCRIPTION OF PP STRAP MAKING MACHINE

This is new technology to use the PET bottle flakes to make the PET

strap. It is of high performance and lower cost.

The products are used: Mould the steel band and is widely used in

the pottery, floor ceramic tile, papermaking, woodwork, fabrics,

cotton, nonferrous metals, chemical products, electric cable and

trays of different articles are tied up, it is the domestic new

developing products

Our PET straps production line, which has broken through the

traditional craft route, takes the 100% bottle slice for raw

materials without any other complement and crystallization, adopts

the advance technology to produce all kinds of polyester straps

directly in a economical cost.

| Product Name | PETΦ120A ONE SCREW 4 STRAPS OUTPUT PRODUCTION LINE |

| Suitable Materia | 100%PET bottle flak ( Material size about10-16MM) |

| Strapping Pcs: | 4pcs |

Strapping Size: | Width/Thickness(mm)5-32/0.5-1.5 |

| Grade | A, fully automatic packing machine use grade Straps |

| Production Capacity | 300-380 kg/h |

FUNCTION

1) PET raw materials do not need to separate the dry and water

treatment. There are automatic circulation on preheating and drying

that save a large number of equipment investment and reduce the

production cost by 30%;

2) Utilizing the retrieving bottle slice as raw materials that

reducing the cost to a great extent;

3) With the multi-purpose machine, produce the PET straps in

different specifications directly and don't need to change the

mould head;

4) Comparing with new polyester slice, the transparency of products

is just the same, but the tensile strength and shock resistance are

up to the international grade;

5) Low Energy consumption, but high production capability;

6)Easy to operate, save the manpower and two persons for one

production line on average.

FAQ

Q1:Are you a trading company or a factory?

Q2:What's your guarantee or the warranty of the quality if we buy your machines?

Q3:When can I get my machine after I paid?

Q4:How about the spare parts?

A4:After we deal down all the things , we will offer you a spare

parts list for your reference.

Q5: What is the payment term?

A5: The best way for both of us is 30% T/T deposit and 70% T/T

balance payment before shipping, since we will test the machine

before shipping. Of course, you can choose the way that more

convenient (Payment terms: T/T, L/C, Western Union etc.)

Q6: How about after service?

A6: We can offer 12 months free warranty since the machinery

arrived at your factory. We also offer space parts or repair

service to our customer anytime and anywhere, we will send our

technician to your factory if necessary.

1.WHY CHOOSE US

We are the Professional manufacturer to develop the plastic

extrusion machines in Shenzhen. Machine quality and customer

satisfaction is our pursuit.Be sure we have the strength to provide

you with quality machines and perfect service.

2.WHAT SERVICES DO WE OFFER?

Pre-sale communication → Design proposal, signature

confirmation→Customized production→ Test machine before shipment

→Package &

delivery→ Engineer installation→Training operator → Technical

support

3.PAYMENT TERMS:

30% of total amount should be paid by T/T as down payment ,the

balance (70% of total amount) should be paid before delivery by T/T

or irrevocable L/C by payment(at sight).

4.DELIVERY CONDITIONS:

4.1 Delivery condition: FOB Shenzhen port or CIF destination Port.

4.2 Delivery terms: Within 30-60 working days after receipt of

advanced payment, the seller should inform the buyer to do

inspection,the seller should finish packing of goods and ready for

shipment within 15 working days after the seller receipt the full

payment.

|