| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Vertical Powder Coating Line |

|---|---|

| Place of Origin: | Guangdong, China |

| Brand Name: | ABD |

| Packaging Details: | Packed in parts with plastic foam in case broken in the process of transporting and loading into the containers or according to customer's requirment. |

| Supply Ability: | 30 Set/Sets per Month |

| Price: | Negotiate |

| Type: | Coating Production Line |

| Substrate: | Stainless Steel Board/Galvanized Sheet |

| Condition: | New |

| Machine Type: | Coating Production Line |

| Video outgoing-inspection: | Provided |

| Machinery Test Report: | Provided |

| Marketing Type: | Hot Product 2019 |

| Warranty of core components: | 1 Year |

| Core Components: | PLC |

| Coating: | Powder Coating |

| Voltage: | 380V/220V |

| Power: | 50W |

| Dimension(L*W*H): | Customized as customer's maximum workpiece |

| Warranty: | 1 Year |

| Key Selling Points: | Engineer onsite installation |

| Applicable Industries: | Building Material Shops, Manufacturing Plant, Construction works , Energy & Mining |

| Showroom Location: | Egypt, United States, Viet Nam, Russia, Thailand, UAE, Australia |

| Weight (KG): | 20000 |

| After-sales Service Provided: | Engineers available to service machinery overseas |

| Pre-treatment: | Chemical pre-treatment or sand/shot blasting machine |

| Water curing off oven: | For baking water |

| Material of powder coating booth: | Galvanized Cold Sheet/PP Panel/Stainless steel sheet |

| Powder Coating Oven: | For baking powder after painting |

| The heating fuel of oven: | Gas/Diesel/LPG/ Electric |

| Evironmental: | Protective |

| Powder Recovery Capacity: | 98% |

| Control system: | Electric panel |

| The conveyor chain speed: | Considering your capacity |

| Company Info. |

| Foshan ABD Equipment Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Tunnel powder coating oven overhead conveyor powder coating line with spraying pre-treatment for electric cabinets

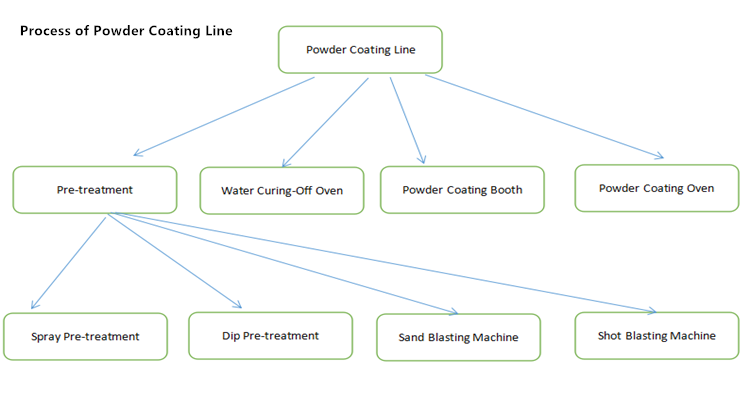

The process of powder coating line mainly includes :

Manual powder coating line and Automatic powder coating line.

One full automatic line mainly include four parts: Pretreatment+water drying oven+powder coating booth+powder curing oven

Pre-treatment:

If you need to clean workpiece,we can manufacture pretreatment for you,if there are too much rust on the workpiece,you should use sand blasting or shot blasting.

If there is not too much rust,you can use spray/dip pre-treatment,the process generally includes phosphating-water rinsing-degreasing-water rinsing,(according to different workpiece and requirment,we will produce pre-treatment according to your request).

Spray Pre-treatment Dip Pre-treatment Sand Blasting Shot Blasting

Water Drying-off Oven and Powder Coating Curing Oven:

After pre-treatment,in order to save time and get great painting effect,the workpiece will come into drying-off oven to cure water.And in most circustance,dryiing-off oven will get together with powder coating curing oven,which can save space.If there are other questions,we can think suitable designing scheme to solve this problem.

After painting,the workpiece will be transported into powder coating curing oven to cure 15-20mins,and the oven is made of 150mm rock wool steel board,and the heating system can choose diesel/natural gas/electric/LPG.The burner adopts Riello brand.And the temperature of powder coating oven is 180 celsius degree to 250 celsius degree.

Powder Coating Booth:

In most circumstance,the booth is made of stainless steel board with filter recycle system,fi youn need to change color quickly,we can design PP Panel powder coating booth with cyclone recycle system to you.

According to your actual condition,we will design the manual/automatic powder coating booth to you.

1. What should we provide if interested in your equipment ?

A.The material/size(max)/weight(max)of your workpieces.

B.What is the expected output of this equipment (8 hours/day,or 30

days/per month )?

C.The available workshop space which you plan to place this set of

equipment(in LxWxH) ?

D.What fuel do you prefer to use for heating

system:Electric,Gas,LPG,Diesel or others?

2.How to install equipment after purchasing your equipment ?

A,We will provide installation documents ,3D assembling drawing or

installation video to guide the installation work.

B.Our engineer will guide the equipment's installation and

debugging on line.

C,We can arrange installers to your factory to guide the

installation work if needed,this service is chargeable.

D,After the debugging, will provide complete training and track the

equipment's usage regularly.

3. How is your company's after-sales service done?

A.1 year parts warranty, parts mainly include fans,burners,electric

components of control cabinet,metal structure,wall panels

etc,except the case of man-made damage.

B. As long as you have been using our equipment, our technical

support will always be online.

|