| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Sany Concrete Pump Parts |

|---|---|

| Brand Name: | Changsha Tongchuang Mechanical |

| Model Number: | DN200/DN230/DN260 |

| Place of Origin: | Changsha, Hunan, China |

| MOQ: | 1 |

| Price: | $140-180 |

| Payment Terms: | D/P, T/T |

| Supply Ability: | 1000 Pieces/month |

| Delivery Time: | 7 work days |

| Packaging Details: | Export standard packing 320*320*50mm |

| Name: | Cutting ring |

| Applicable model: | Applicable to all models of Sany concrete pump/pump truck /truck-mounted pump |

| Specifications and models: | DN200/DN230/DN260 |

| Weight: | 11KG |

| Useful life(m³): | 15000 |

| Specification size: | 320*320*50mm |

| Hardness of surfacing layer(HRC): | ≥65 |

| Material: | Super wear-resistant materials |

| Company Info. |

| Changsha Tongchuang Mechanical Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

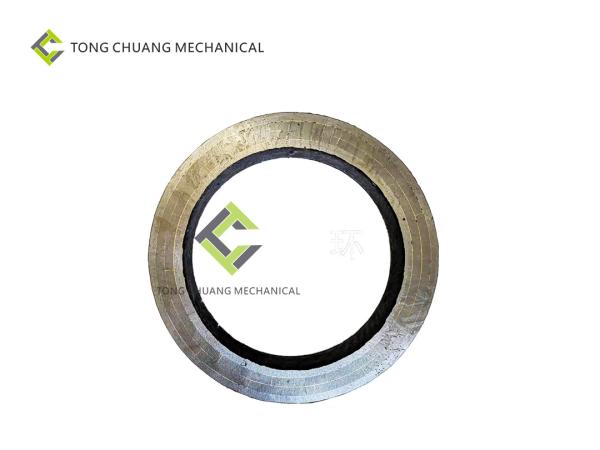

Sany Concrete pump parts cutting ring DN200/DN230/DN260

| Sany Concrete pump parts cutting ring DN200/DN230/DN260 | |

| Name | Cutting ring |

| Place of origin | Changsha, Hunan, China |

| Brand name | Changsha Tongchuang Mechanical |

| Applicable model | Applicable to all models of Sany concrete pump/pump truck /truck-mounted pump |

| Specifications and models | DN200/DN230/DN260 |

| Specification size | 320*320*50mm |

| Weight | 11KG |

| Hardness of surfacing layer(HRC) | ≥65 |

| Useful life(m³) | 15000 |

| Material | Super wear-resistant materials |

| Supply capacity | 1000 Pieces/month |

| Packing | Export standard packing 320*320*50mm |

| Minimum order | 1 |

| Price | $140-180 |

Product features and advantages:

1,High wear resistance, stable quality, high wear resistance and

average service life ≥ 15,000m³.

2,Adopting double alloy structure, the alloy's brazing fullness

reaches 100%, which effectively reduces welding stress and

completely eliminates alloy chipping.

3,The Original factory design ensures the installation quality and

pumping seal, which is conducive to prolonging the service life of

hopper, transition sleeve, S pipe and other related parts.

Maintenance method:

1,Regularly check the gap between the spectacle plate and the

cutting ring. Once the gap increases, immediately tighten the

special nut or replace the worn parts to prevent mortar from

entering the friction surface.

2,Rotate the cutting ring regularly to make it wear evenly.

Generally, it takes about 100 hours to rotate the cutting ring by

90︒

3,After the pump is finished, the contact surface between the

spectacle plate and the cutting ring should be washed with water to

prevent fine sand from adhering to the gap between the spectacle

plate and the cutting ring.

|