| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Underground Truck Hydraulic Pumps |

|---|---|

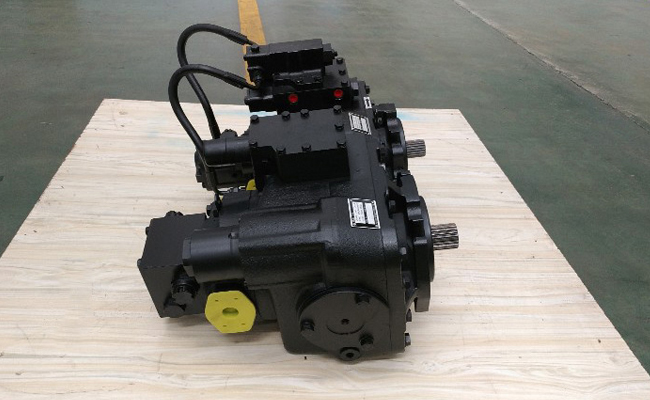

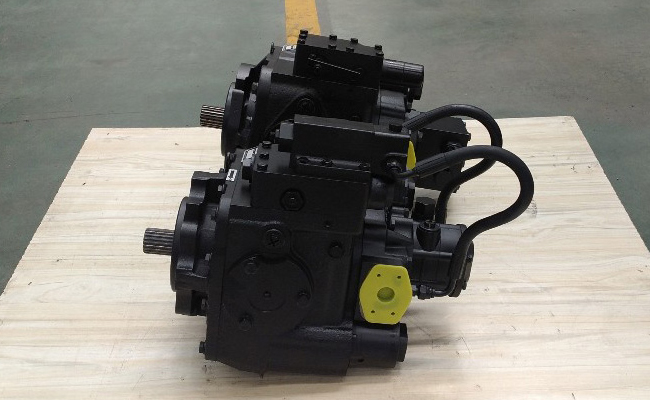

| Brand Name: | HIGHLAND |

| Model Number: | PV22+MV23 |

| Certification: | PATENT CERTIFICATE |

| Place of Origin: | CHINA DEZHOU |

| MOQ: | 1 set |

| Price: | USD 2300/set |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 100 sets per month |

| Delivery Time: | 9 work days |

| Packaging Details: | plywood case |

| Model: | PV22+MV23 |

| Type: | Hydraulic components |

| Features: | lifetime technical support |

| Material: | Cast iron |

| Application: | Industrial machinery underground truck hydraulic pumps |

| Medium: | Hydraulic oil |

| Warranty: | 1 year |

| Function: | Hydraulic system components |

| Package: | Plywood case |

| Product name: | Industrial machinery underground truck hydraulic pumps reliable quality |

Industrial machinery underground truck hydraulic pumps reliable quality

Quick Detail:

· Cast iron housing

· Hydraulic components

· Model PV22+MV23

· Hydraulic system power components

· Principle hydraulic transmission

· Features lifetime technical support

· Simple layout

· System Solutions

· Work fast

· Fully replace imported products

· Patent certificate certification

· Application industrial machinery underground truck hydraulic pumps

· 1 year warranty

Description:

How to use the scraper?

(1) If the scraper is not in use, the soil and dust on it should be

removed, and it should be parked on a relatively flat ground. Smoke

and place the bucket on the ground, the bucket door is closed, and

the unloading device is retracted to the back of the bucket , Turn

off the engine, firmly support the mop with wooden blocks, use

triangular wooden blocks to clamp the front and rear wheels, pull

out the traction pins, move each joystick up and down several times

to prevent fuel injection, disengage the quick connector, and use

the cap Cover it well. If it is parked on uneven ground for a short

time, use the bucket locking pin and hang the bucket on the

cylinder of the gantry to prevent the bucket from being deformed.

(2) The scraper is suitable for earth work, not suitable for stone

work. It can still work on a small amount of rock and soil, but if

it encounters a slightly larger stone, wood, metal or obstacle when

shoveling soil, it should stop immediately. Excluded. It is

forbidden for the scraper to work in stagnant clay or in rainy

weather. In the area exceeding the comprehensive slope limit, that

is, when the longitudinal slope is > 10%, and the lateral slope

> 18%, in order to avoid the scraper from dumping or a The side

tires are too stressed, and the scraper is not allowed to work.

PV22+MV23 Technical parameter:

| PV22 hydraulic pump and MV23 hydraulic motor series | PV22 | MV23 | ||

| Displacement | Max displacement | ml/r | 69.8 | 89 |

| Speed | Max continuous working speed (Full load condition) | r/min | 3200 | 3200 |

| Rated speed | r/min | 2500 | ||

| Min continuous working speed | r/min | 500 | ||

| Pressure | Rated working pressure | Mpa | 35 | |

| Max working pressure (transient) | Mpa | 42 | ||

| Continuous working pressure | Mpa | 30 | ||

| Allowable shell pressure (Absolute) | Mpa | Constant0.25, Peak value0.5 | ||

| Torque | Continuous output torque (Under continuous working pressure) | Nm | 342.6 | 432.9 |

| Max output torque | Nm | 480 | 606 | |

| Power | Continuous output power | KW | 107 | 139 |

| Max power | KW | 114 | 150 | |

| Temperature | Allowable shell temperature | ℃ | 80 | |

| Max working temperature of oil tank | ℃ | 70 | ||

| weight | PV series hydraulic pump hydraulic oil drain | kg | 62 | |

| PV series hydraulic motor hydraulic oil drain | kg | 66 | ||

Notices:

Hydraulic oil

The suitable replacement period for hydraulic oil in a sealed tank

system is 2000 hours, and more often if the hydraulic oil is

contaminated with water or other external materials or subjected to

abnormal operating conditions.

As a general recommendation, the 10µ inlet oil filter should be

replaced every spring or every 1500 hours (whichever occurs first)

on a sealed tank system, or in an open tank system with an air

filter fill cap. The oil filter should be replaced every 500 hours.

Heat Exchanger

The heat exchanger core and fins are kept clean at all times for

maximum cooling and system efficiency, and the exterior of the heat

exchanger is checked daily for blockages and cleaned as needed.

Application:

Mixer truck: concrete mixer truck, cement mixer truck;

Coal mining machinery: scraper;

Industry: pharmaceutical machinery;

Transport vehicles: road rollers, concrete pump trucks, stabilized

soil mixers

FAQ:

Q1. Can I have a sample order for industrial machinery underground truck hydraulic pumps easy to use?

A: Yes, we welcome sample order to test and check quality.

Q2. What about the lead time?

10 to 15 days for samples, mass production according to MOQ

Q3. Do you have any MOQ limit for industrial machinery underground truck hydraulic pumps easy to use?

A: Low MOQ, 1pc for sample checking is available.

Q4. How do you ship the goods and how long does it take to arrive?

Ship by sea, it generally takes 15-20 days to arrive, and air is also optional.

Q5. How to proceed an order for industrial machinery underground truck hydraulic pumps easy to use ?

A: Firstly let us know your requirements or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms the samples and places deposit for formal order.

Fourthly We arrange the production.

Q6: Do you offer guarantee for the products?

A: Yes, we offer 1 years warranty to our products.

Q7: How to deal with the faulty?

Firstly, our products are produced in strict quality control system.Secondly, we will inspect the defective pump and motor, and then respond according to the actual situation.

|