| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Horizontal Decanter Centrifuge |

|---|---|

| Brand Name: | Juneng |

| Model Number: | LW430 |

| Certification: | ISO9001& ISO14001 |

| Place of Origin: | JIANGSU Nanjing |

| MOQ: | 1 set |

| Price: | USD15000~100,000/set |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50 sets /months |

| Delivery Time: | 30~50 days |

| Packaging Details: | seaworthy packing |

| Other name: | Tricanter for aging oil |

| Voltage: | 220V, 380V,440V,460V |

| Material: | SS304, SS316L, SS2205 |

| Control: | Automatic control |

| Speed: | Inverter Control |

| After-sales service provided: | Online support |

| Company Info. |

| JUNENG MACHINERY (CHINA) CO., LTD. |

| Verified Supplier |

| View Contact Details |

| Product List |

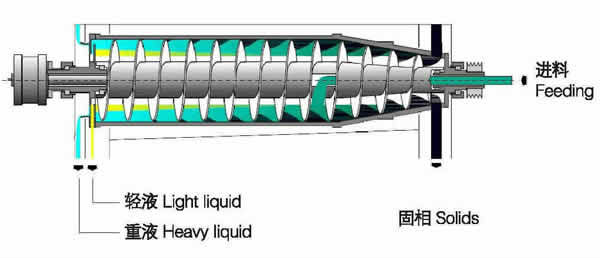

The three-phase separation decanter centrifuge is a fully enclosed, fully automatic and continuous process for the treatment of aging oil. This product has been successfully used in Daqing Oilfield and Liaohe Oilfield.

The aging oil from the storage tank has a high viscosity due to a long deposition time, so it must be heated and a demulsifier added to reduce the viscosity. The aged oil enters the three-phase decanter centrifuge through the pump, and the centrifuge rotates at a high speed. Under the action of a large centrifugal force, the solid (sludge) with high density settles on the drum wall. Two liquid phases with different densities form concentric cylinders, with the lighter liquid phase (oil) in the inner layer and the heavier liquid phase (water) in the outer layer. The thickness of different liquid rings can be adjusted by the liquid adjusting plate. The sludge deposited on the drum wall is conveyed by the screw conveyor to the cone end of the drum body, and discharged from the discharge port. It can be transported to the designated place by the conveyor belt. A trolley can also be used to transport sludge. The separated oil is transported to the storage tank through the oil discharge pipeline, and the separated water is also discharged through the drainage pipeline.

Working principle :

| Diameter | 430mm | Voltage : | 220V, 380V,440V,460V |

| Speed | Inverter Control | Electrical Components: | World Famous Brand |

| Operation | Continuous | Separation : | Three phase |

| Bearing | SKF | Material : | SS304, SS316L, SS2205 |

| Control | PLC | Motor : | 2 |

Other Applications :

The 3-phase decanter separates which contains oil into an oil phase, solids and virtually oilfree waste water. Because of its high dry matter, the solids can be recycled relatively easily.

In addition, the solids concentration in the waste water is lower than would be the case if nozzle separators are used in conventional process.

Advantages :

1. Lower cake transportation costs due to very dry solids

2. Better recovery of nutrients due to very high separation efficiency

3. Lower fresh water consumption compared to other processes

4. Continuous and fully automatic operation

5. 24 h operating reliability

6. Optimum wear protection

7. Energy saving design

8. Easy to operate

9. Easy to maintain

10. Simple assembly/dismantling

Features :

Technological Data :

| Model | Drum diameter mm | Inlet liquid capacity㎥/h | Power of main/auxiliary motor Kw | Weight Kg | Dimension (max) mm |

| LW250 | 250 | 1-4 | 11/4 | 1200 | 2650*720*900 |

| LW(F)250 | 250 | 1-4 | 11/4 | 1200 | 2650*720*900 |

| LW250(W) | 250 | 1~5 | 11/4 | 1300 | 2750*720*900 |

| LW350 | 350 | 5~15 | 22/5.5 | 2000 | 3585*980*1238 |

| LW(F)350 | 350 | 5~15 | 22/5.5 | 2000 | 3585*980*1238 |

| LW350(W) | 350 | 5~18 | 15/5.5 | 2200 | 3412*1090*950 |

| LW(S)350 | 350 | 2~10 | 22/5.5 | 2000 | 3676*980*1238 |

| LW450 | 450 | 5~20 | 30/11 | 3000 | 4380*1080*1360 |

| LW(F)450 | 450 | 5~20 | 30/11 | 3000 | 4380*1080*1360 |

| LW450(W) | 450 | 5~28 | 30/11 | 3200 | 4380*1080*1360 |

| LW(S)450 | 450 | 5~15 | 37/11 | 3200 | 4195*1080*1360 |

| LW520 | 520 | 10~26 | 45/15 | 5000 | 4840*1160*1465 |

| LW(F)520 | 520 | 10~26 | 45/15 | 5000 | 4840*1160*1465 |

| LW520(W) | 520 | 10~35 | 45/11 | 5000 | 4840*1160*1465 |

| LW550W | 550 | 10-45 | 55/11 | 6500 | 5038*1388*1578 |

*** F: Ex-proof, W:Waste water, S: Three phase FS:Ex-- proof and three phase

Factory :

|