| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | CNC Turning Milling Parts |

|---|---|

| Brand Name: | PFT |

| Model Number: | OEM |

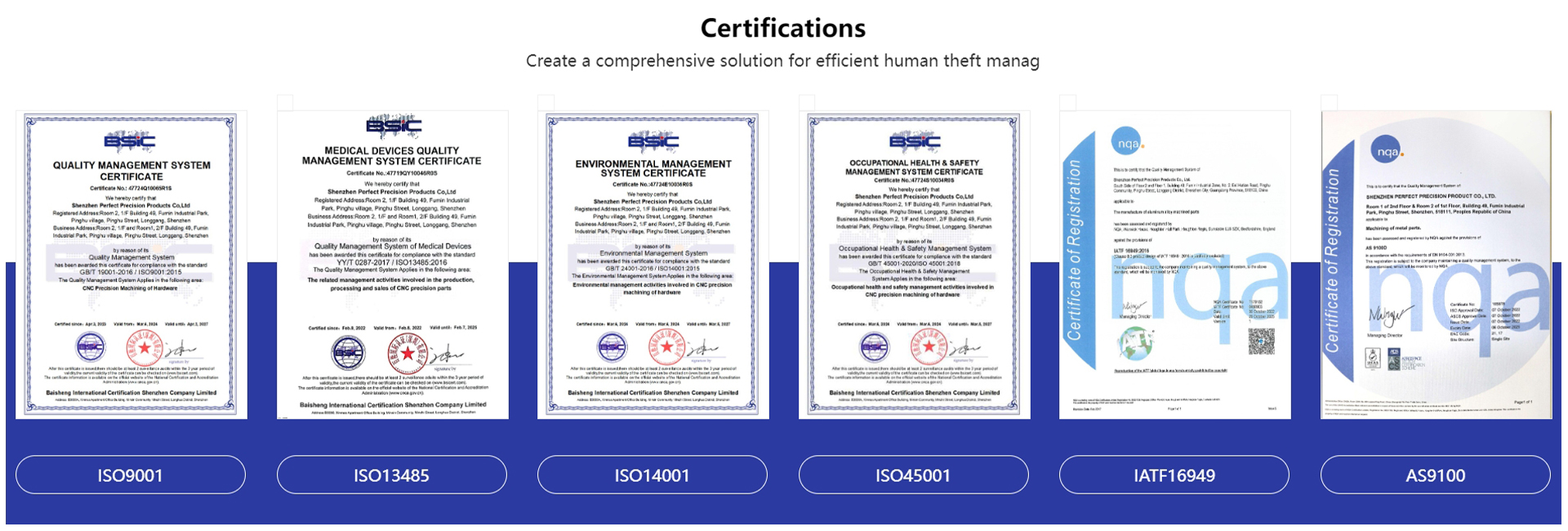

| Certification: | ISO9001:2015,ISO13485:2016 |

| Place of Origin: | Guangdong,China |

| MOQ: | 1PC |

| Price: | Nigotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

| Supply Ability: | 10000Pcs/Month |

| Delivery Time: | 7-15 Work days |

| Packaging Details: | As the requiament of custome |

| Service: | Customized OEM |

| Drawing format: | |

| Lead time: | 7Days |

| Services: | OEM & ODM & Design & Assemble Services |

| Key Words: | CNC Turning Milling machining |

| Item: | Plastic Injection Parts |

| High Precision: | 0.005mm |

| Port: | shenzhen |

| Function: | Enhance Machine Performance |

| Delivery: | By Sea/Air/Express |

| Design Software: | CAD UG CAM,STP,Solidworks and so on |

| Weight: | Customized |

| Type: | Machining Parts |

| Cutting Thickness: | Materials |

| Durability: | Long-lasting |

| Roughness: | Ra0.4-Ra0.8 |

| Advantage: | High Precision, Fast Delivery, Etc. |

| Company Info. |

| Shenzhen Perfect Precision Product Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

In advanced manufacturing, combining silicone injection molding with CMC turning milling parts offers a unique and powerful solution for producing precision-engineered components. This hybrid manufacturing approach is especially useful in industries where flexibility, durability, and tight tolerances are essential—such as medical devices, automotive systems, electronics, and aerospace applications.

What is Silicone Injection Molding?

Silicone injection molding is a process used to produce parts from liquid silicone rubber (LSR) by injecting it into a heated mold cavity where it cures. This method is widely used for manufacturing flexible, durable, and biocompatible components.

Key features of silicone injection molding:

Common applications:

What Are CMC Turning and Milling Parts?

CMC (Ceramic Matrix Composite) materials are a class of advanced ceramics reinforced with fibers, offering superior performance at high temperatures and in corrosive environments. CMCs are used in components where traditional metals or plastics would fail due to thermal stress or wear.

Turning and milling are CNC (Computer Numerical Control) processes used to shape these extremely hard and brittle materials with high precision.

Benefits of CNC turning and milling for CMC parts:

Common CMC materials:

Applications include:

Design Considerations

When designing products that incorporate both processes:

1. Are you a manufacturer or a trading company?

|

|