| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | CNC Machined Aluminum Parts |

|---|---|

| Brand Name: | YMP |

| Model Number: | YMP-j0484 |

| Place of Origin: | Guangdong, China |

| MOQ: | 100 |

| Price: | $0.976-1.067 piece |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 3000 pieces per day |

| Delivery Time: | 7 days |

| Packaging Details: | Inner pearl button, outside carton box, or customized |

| Material: | Aluminum |

| Process: | Stamping |

| Surface treatment: | Painting\Powder Coating\Plating\Polishing |

| Product name: | aluminum enclosures |

| Application: | Industry |

| Service: | Customized OEM |

| Size: | Customized Size |

| Color: | Customized Color |

| Type: | OEM Parts |

| Drawing format: | 3D/CAD/DWG/IGS/STEP/PDF |

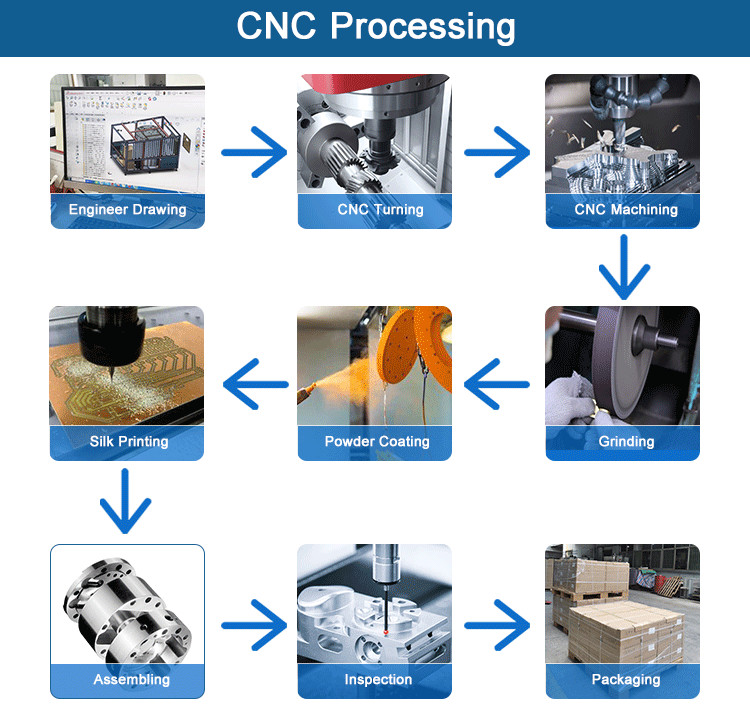

YMP was established in 2004 and is located in Shenzhen city, enjoying convenient transportationano bountiful supply of aluminium raw material and meta processing industry. YMP is the integrator of CNC machining china manufacturers for solve customers problems. YMP work with SMEs to serve customers worldwide. With over 100 suppliers and 156 machines and 100 technicians, our prides itself on outstanding customer service and customer communications while delivering a quality product on time.

Our supply chain has rich experience processes such as CNC machining, turning, milling, welding, forming, rolling, cutting, stamping, etc. Our main products include screw machine products & turned parts, maximum part length is 4 inches.

High Precision Mold | ||||

Core/cavity material: | SKD11, D2 etc. | |||

Material: | A3, 45# steel | |||

Type: | press stamping, progressive press, deep drawing | |||

Mould life: | 300,000 shoots | |||

Size/Tolerance: | According to customer's 2d drawing | |||

Monthly capacity: | 50000pcs | |||

Design Software: | PROE, UG, CAD,Solidwork | |||

Order processing procedures | ||||

1. Confirm drawing, order qty, surface treatment, packing, shipping

and price. | ||||

2. Make pre-production samples. | ||||

3. Mass production. | ||||

4.Customer inspection or self-inspection as customer's

requirements. | ||||

5. Arrange shipment. We can provide shipping assistants, customers

can also arrange shipments themselves. | ||||

The application of PVDF is mainly concentrated in three fields: petrochemical industry, electronic and electrical industry and fluorocarbon coatings. Because of its good chemical resistance, processability, fatigue and creep resistance, it is one of the best materials for petrochemical equipment fluid handling system as a whole or lined pumps, valves, pipelines, pipe fittings, storage tanks and heat exchangers.

Because of its good chemical stability and electrical insulation, the manufactured equipment can meet the requirements of TOCS and flame retardance, and it is widely used in the storage and transportation of high-purity chemicals in the semiconductor industry. In recent years, porous membranes, gels and separators made of PVDF resin have been used in lithium secondary batteries, and now this application has become one of the fastest growing markets for PVDF.

Shenzhen Yixin Precision Medical and Plastic Ltd has accumulated 20 years' experience in the design and processing of PVDF parts. The following are common processing methods of PVDF:

PVDF can be processed by general thermoplastic processing methods, such as extrusion, injection molding, pouring, molding and transfer molding.

Most CNC factories only focus on CNC machining, but are not good at surface treatment. If the surface treatment of parts does not meet expectations, it will not only increase the cost, but also affect the time to market of products.

YMP has rich experience in surface treatment of metal parts, and we will choose suitable surface treatment process according to different parts materials and uses.

The common surface treatments of YMP include: electroplating, electrophoresis, painting, powder spraying, sand blasting, polishing, shot blasting, laser engraving, etching, CD pattern, silk screen printing, wire drawing, blackening, anodizing, hard oxidation, thick film oxidation, micro-arc oxidation and so on. No matter what personalized requirements your parts need, we can meet them.

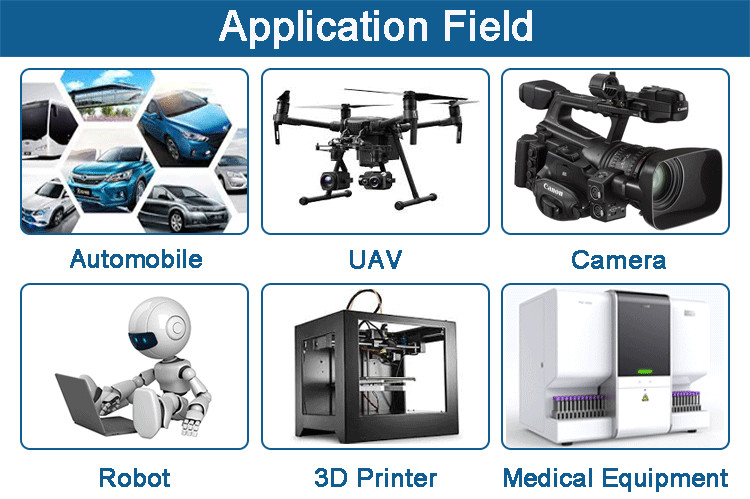

There are various parts that can be processed by CNC, involving a wide range of industries.

YMP has many years of experience in making OEM parts, and there are 475 kinds of materials. Basically, we can process all the metal materials in the market, and we are equipped with spectrometers to ensure the authenticity of the materials. So you don't have to worry about material problems when you choose YMP. We have stocks of aluminum alloy, stainless steel, magnesium alloy, titanium alloy, zinc alloy, nickel alloy, copper, steel, and so on.

A1: We are a manufacturing factory. Click Here, and we will contact you as we receive your mail.

A2: Yes, customer design, especially OEM, is welcomed. Please feel free to send us your design for development, Leave a message

A3: Yes, we have certain preferential policies for our own branded company and our VIP customer list.

A4: Usually we don't set MOQ, but the more, the cheaper. Besides, we are happy to make prototypes or samples for clients to ensure quality standards. Get the exact delivery date.....

A5: The price on the website is only a rough quotation. Many factors such as quantity, material cost, and the exchange rate will affect the price, so the real price will be subject to our final confirmation.

A8: We regret that we are unable to remake it once one order is produced. We don’t have any refund policy for confirmed and flawless products, but we accept your changes before we send the order to production.

A7: If you are not satisfied with the goods received, please contact us. Any problems can be negotiated! We promise to find a good solution and reply to you ASAP. Get a fast reply

A8:Kindly please provide the product drawing in PDF, and will be better if you can provide it in dwg/. stp /.igs /.stl, Send drawing

|