| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Metal Bending Parts |

|---|---|

| Brand Name: | YMP |

| Model Number: | YMP-j0667 |

| Place of Origin: | Guangdong, China |

| MOQ: | 100 |

| Price: | $0.828-1.304 piece |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 3000 pieces per day |

| Delivery Time: | 7 days |

| Packaging Details: | Inner pearl button, outside carton box, or customized |

| Material: | Stainless Steel |

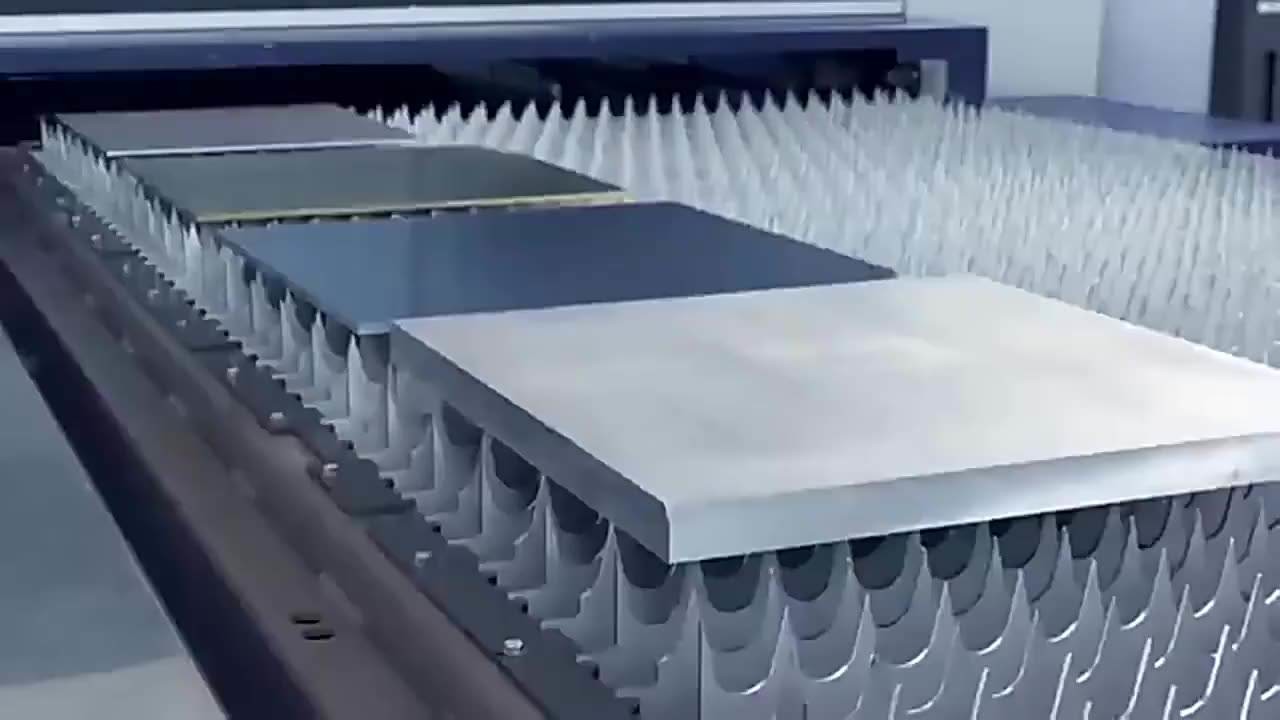

| Process: | Laser Cutting |

| Surface treatment: | Painting\Powder Coating\Plating\Polishing |

| Product name: | laser cutting metal sheet fabrication |

| Application: | Industry |

| Service: | Customize ODM OEM |

| Size: | Customized Size |

| Color: | Customized Color |

| Type: | Stamping Hardware Part |

| Drawing format: | 3D/CAD/DWG/IGS/STEP/PDF |

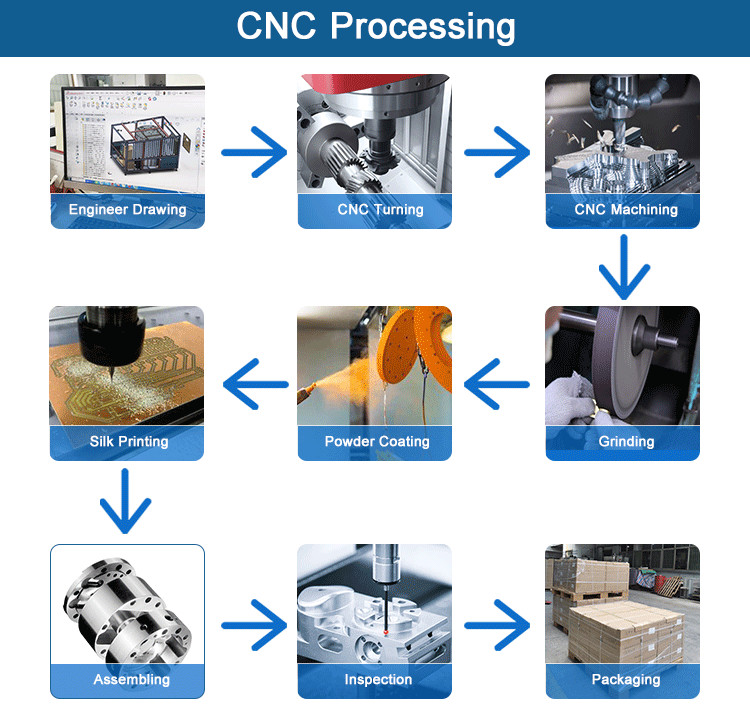

YMP is committed to customizing high-precision CNC machining parts. We have 18 years of OEM and ODM experience in customized products. Over the years, we have introduced many high tech equipment, such as 5-axis CNC machining centers, which enable us to manufacture complex and micro machined precision parts faster than ever before.

In addition, we also have long-term and close cooperation partners in sheet metal, stamping, injection molding, and die casting, so we can provide a one-stop service to complete your entire project.

Our engineers are experienced and can provide some suggestions when you need them. Our inspectors carefully check every detail of the product before packaging it to ensure that the product meets the customer's requirements.

Our products have been sold to more than 30 countries around the world, including Canada, the United States, France, Italy, Switzerland, Poland, Australia, New Zealand, etc.

Most of our customers benefit from our OEM service. We have been able to provide total solutions for customers in various industries. To find out if we are the right OEM for you, please contact us today.

Aluminum alloy | 1100, 2A12, 2017, 3003, 5052, 5083, 6061, 6063, 6082, 7075,etc | |

Stainless steel | SS201, SS303, SS304, SS316 etc | |

Brass | C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37),

C28000 (CuZn40) etc | |

Bronze | C51000, C52100, C54400, etc. | |

Iron | 1213, 12L14, 1215 etc | |

Steel | Q235, 20#, 45#, Gear steel, bearing steel, tool steel, low carbon

alloy steel, powder metallurgy, special alloy | |

Die-cast material | Normal engineering plastic | ABS,PC,PA,PP,PMMA,POM,PET,PBT,PVC,etc |

Advanced Engineering Plastics | PA66,PA66+GF30,PA66+GF50,,PA46,PPS,PPS+GF,PEEK,PEI,PAI,

PBT+GF,PTFE,etc | |

zinc alloy panel | zmark3, zmark5 | |

QPQ is the abbreviation of Quench-Polish-Quench, which means that ferrous metal parts are put into two salt baths with different properties, and multiple elements infiltrate into the metal surface to form a composite infiltration layer, so as to achieve the purpose of surface modification of the parts. It has good wear resistance, fatigue resistance, corrosion resistance, and small deformation. This process is suitable for all steel materials. (Note: Stainless steel products can't be blackened, only QPQ can be used to blacken the surface)

Most CNC factories only focus on CNC machining but are not good at surface treatment. If the surface treatment of parts does not meet expectations, it will not only increase the cost but also affect the time to market products.

YMP has rich experience in the surface treatment of metal parts, and we will choose a suitable surface treatment process according to different parts' materials and uses.

The common surface treatments of YMP include: electroplating, electrophoresis, painting, powder spraying, sandblasting, polishing, shot blasting, laser engraving, etching, CD pattern, silk screen printing, wire drawing, blackening, anodizing, hard oxidation, thick film oxidation, micro-arc oxidation and so on. No matter what personalized requirements your parts need, we can meet them.

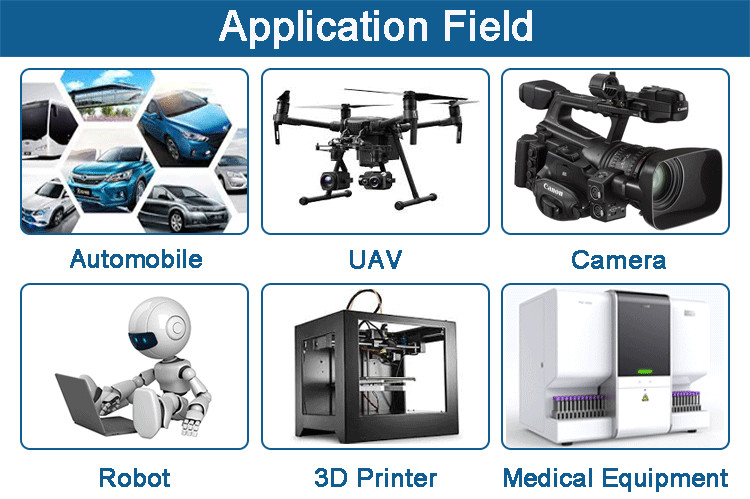

There are various parts that can be processed by CNC, involving a wide range of industries.

YMP has many years of experience in making OEM parts, and there are 475 kinds of materials. Basically, we can process all the metal materials in the market, and we are equipped with spectrometers to ensure the authenticity of the materials. So you don't have to worry about material problems when you choose YMP. We have stocks of aluminum alloy, stainless steel, magnesium alloy, titanium alloy, zinc alloy, nickel alloy, copper, steel, and so on.

A1: We are a manufacturing factory. Click Here, and we will contact you as we receive your mail.

A2: Yes, customer design, especially OEM, is welcomed. Please feel free to send us your design for development, Leave a message

A3: Yes, we have certain preferential policies for our own branded company and our VIP customer list.

A4: Usually we don't set MOQ, but the more, the cheaper. Besides, we are happy to make prototypes or samples for clients to ensure quality standards. Get the exact delivery date.....

A5: The price on the website is only a rough quotation. Many factors such as quantity, material cost, and the exchange rate will affect the price, so the real price will be subject to our final confirmation.

A8: We regret that we are unable to remake it once one order is produced. We don’t have any refund policy for confirmed and flawless products, but we accept your changes before we send the order to production.

A7: If you are not satisfied with the goods received, please contact us. Any problems can be negotiated! We promise to find a good solution and reply to you ASAP. Get a fast reply

A8:Kindly please provide the product drawing in PDF, and will be better if you can provide it in dwg/. stp /.igs /.stl, Send drawing

|