| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Hot Dip Galvanizing Line |

|---|---|

| Brand Name: | JJRS |

| MOQ: | 1set |

| Supply Ability: | 10-12 set/year |

| Delivery Time: | 7~10 months |

| Packaging Details: | wooden box; plastic package |

| Material: | Cold Rolling Coil, Hot Rolling Acid Pickling Coil |

| Thickness: | 2.0~3.0mm |

| Width: | 450mm |

| Annual Output: | 120,000 ton |

| Type: | continuous |

| Coating: | Galvanizing, Painting, Plating, Hot dip galvanizing, zinc coat |

| After-sales service provided: | Engineers available to service manchinery overseas, field installation, online support |

| Name: | Continuous Galvanizing Line |

| Production mode: | double/single work line |

| Price: | USD$1,000,000~USD10,000,000 |

New Generation Steel Strip Continuous Annealing

Hot Dip Galvanizing (Aluminizing) Technology --- JJRS-Sendzimir

Consolidating the advantages of the traditional technology " Improved Sendzimir" and "United States Steel Corp", and integrating the independently researched and developed regenerative nozzle and waste heat efficient recycling technology, the technology R&D team of Beijing JJRS Technology Development Co.,Ltd, launched a new generation of steel strip continuous annealing hot dip galvanizing process contrl technology based its latest self-designed process control technology by in-depth study and analysis, which is named as " JJRS-Sendzimir".

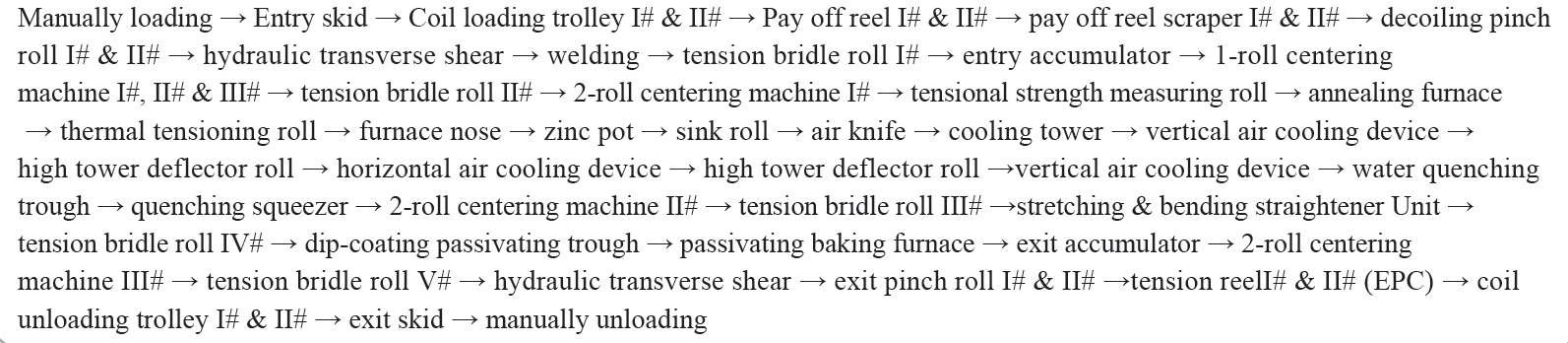

The continuous high-speed hot rolled galvanizing lines include the following sections, assemblies, and machines:

Input section:

1. Coil rack

2. Loading carriage

3. Dual decoiler system- -Alternative operation of decoilers, coil weight 10 to 40 t

4. Two thickness gages - Designed for initial strip thickness control

5. Dual guillotine shears - for cutting the beaded edges of the

strip in the alternatively used coils

Butt-welding machine - is equipped with straightener rollers and

performs welding of strip ends of two coils; weld thickening no

more than 10%, weld strength no less than 85% of the main strip

characteristics

6. Looping pit

7. Disc shears - Designed for cutting the strip side edges;

shearings are cut up by scrap cutter

8. Stretching machine

9. Stretching rollers

10. Multistorey storage loop (accumulator) - Automatically monitors

the strip stock and has end trolley for constant stretching of the

strip.

Strip electrochemical cleaning section

The strip is cleaned in baths with alkali solution; after that, it

is washed and dried in a way similar to that described for the

strip pickling line above.

Strip hydro-dynamic cleaning section

1. Guide rollers

2. Two vacuum housings

3. Dual rotary blowers

4. Dual high-pressure pumps

5. Two cyclone separators

6. Circulation water treatment system

| Supplied To | Country | Capacity | Start U |

| AME Steel | Tailand | T/Y (No.1 CAL) |

|---|

| JIANLONG | China | T/Y (No.3 CAL) |

|---|

| HUXIN | China | T/Y (No.1 CAL) |

|---|

| IMI | ASIA | T/Y (Tin CAL) |

|---|

| Iron & Steel | China | T/Y (No.3 CAL) |

|---|

|