| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Tube Cold Saw |

|---|---|

| Brand Name: | JCCS |

| Model Number: | JCCS-32 |

| Place of Origin: | HeBei China |

| MOQ: | 1 set of |

| Price: | Negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 20 Set/Sets per Month |

| Delivery Time: | 15-30 work days |

| Packaging Details: | Usually a high quality steel square tube making machine is loaded in a container. Depends on the size and weight of the machine. |

| Product name: | Cold Cutting Flying Saw |

| Origin: | China |

| Applicable industries: | Building material stores, manufacturing plants, mechanical repair shops, construction works, energy and mining |

| Core components: | PLC, bearing, gear |

| Pipe shape: | Round/square/rectangular tube |

| Main selling point: | Remote control |

| Application: | Drain pipe |

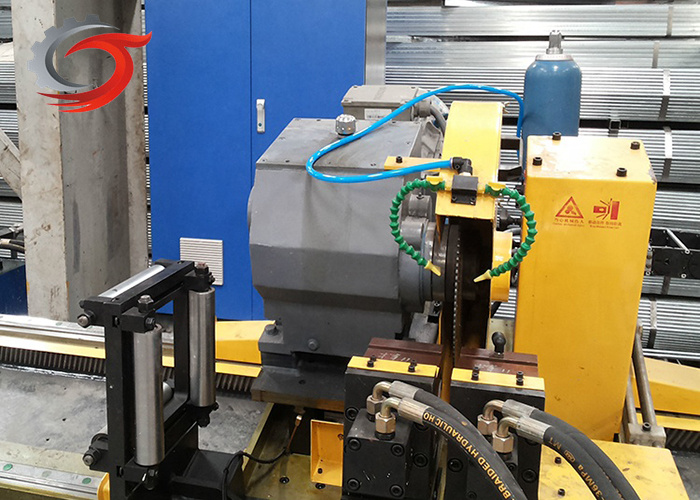

CNC pipe cutting machine pipe machine flying saw pipe mill process high speed

Introduction

There is no need for any facing or chip removal, even in hollow sections, resulting in a clean cut of the end. The machine is fully CNC and very user friendly. Ideal for low carbon and stainless steel, the machine is equipped with a console with the most modern MMI to provide the operator with accurate production status and extensive troubleshooting.

| material | Q195 Q235 SPCC | |

Cutting range | Round tube:MAX53mm | thick:0.5~2.5mm |

| Square tube:MAX40×40mm | thick:0.5~2.5mm | |

| Rectangular tube:MAX 30×50mm | thick:0.5~2.5mm | |

| Production speed | 120m/min(length 6 meter,dia.≤25mm) | |

| Power supply | AC380V,3PH,50HZ | |

| Mechanical length | 4420*1280*1280mm(as per final drawing) | |

Motor list | Drive:15KW | PHASE servo motor |

| saw: 11KW | Siemens AC motor | |

| Linear guide | Hiwin Chinese Taiwan | |

| Gear rack | KH from Chinese Taiwan | |

| Cable protection | Drag chain | |

| Carriage protection | Safety bumpers for carriage are equipped at both ends | |

| Equipment document | User’s manual & electrical diagram | |

Features

Our product range is designed with high quality raw materials such as stainless steel and mild steel and is widely used in the construction of various construction equipment.

our service

1. Professional pre-sales consultation and after-sales service to

help you find the best solution

2. Discuss technical details with our professional engineers

3. Strictly control the quality and production plan of the cold

flying saw. You will be kept informed of any progress

4. Check the cold flying saw before shipment

5. After the warranty period, spare parts are provided at cost

6. Professional engineers help you increase production, reduce

waste and reduce costs

7. Control the production progress and quality of the machine, and

provide you with detailed information in time

|