| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Multi Cavity Injection Moulding |

|---|---|

| Brand Name: | Custom LOGO |

| Model Number: | HW-624 |

| Certification: | ISO9001 |

| Place of Origin: | China |

| MOQ: | 1set |

| Price: | 2000-10000USD |

| Payment Terms: | T/T , Paypal |

| Supply Ability: | 40sets/month |

| Delivery Time: | 25-40days |

| Packaging Details: | wood carton, as customer requested |

| Name: | Plastics injection molding |

| Mold Design software: | PRO/E, Solidwork, UG, Autocad, etc |

| Plastic Material: | ABS, PC,PP,PET, PETG,PVC,TPE,TPU etc |

| Mould Base: | FUT, ABA, LKM, HASCO, DME |

| Mould size: | Any size as per customer's requirement |

| Lifetime: | >300 Thousand Times |

| Product weight: | 1g-5kgs |

| Delivery time: | 20-35 Days |

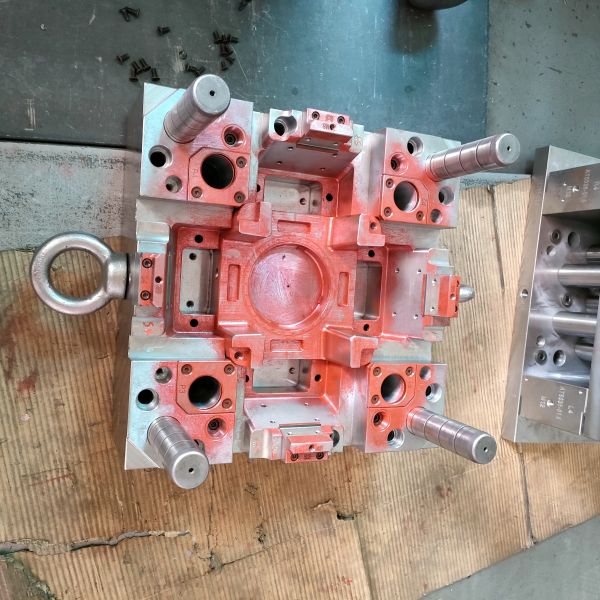

Custom Mobile Plastic Casing Injection Tooling in Dongguan

Custom Mobile Plastic Casing Injection Tooling With TPU Plastic Raw Material

We meets the demand for affordable, durable plastic products that require precise specifications every time. We are your one-stop source for quality, cost-competitive molded plastic products using a variety of plastic materials.

| Name | Custom made plastic parts Injection moulding |

| Type of plastic mold | 3-plate mold,2-plate mold |

| Mold base | LKM 50 standard mould base or Self-made |

| Mold runner | Hot/Cold Runner |

| Base material | P20,P20H,718,718H,738,738H,2316,M300,S136,S136H,NAK80,CR12,CR12MOV,SKD11,DF-2,SKS3,D2,SLD,DC53,H13,SKD61,2344,8407,HD,8418,FDAC,M2,SKH-9 ,SKH-51,M35,M42,ASP23 |

| Mold Cavity | 1*1,1+1,1*2,1+1+1,etc |

| Diameter | 5-1000mm,or customized |

| Product Material | ABS, PA, PA66+30GF, PBT, PC, POM, PP, PE, PMMA,PVC,TPE,TPU etc |

| Color | White,black,green,nature,blue,yellow,etc |

| Treatment | S45C Pretreat>25Hrc,And Nitriding |

| Inserts(cavity and core) | H13, 1.2344, 1.2738, 1.2083, 1.2311, NAK80 or the material you required. |

| Gate type | Side gate,Sub gate,Pin point gate,Edge gate etc |

| Shape | Sheet, rod, tube, gear, pulley, guide rail, or as per your drawing |

| Ejection system | Stripper plate,Lifter,Push bar,Ejection pin etc |

| Design software | Pro/E,UG,Catia,Woodwork,Moldflow,AutoCad |

| Mold of steel suppliers | FINKL,Assab,DAIDO,LKM,Buderus |

| Hot Runners suppliers | Synventive,YUDO,INCOE,HASCO,DME,MOLDMASTER,HRS,DELACHAUX,SINO |

| Certification | ISO9001,SGS,Test Report,RoHS |

| Lifetime | >300 Thousand Times |

| Shipping Packing | Wood case or carton box 1. With plastic bag, with pearl-cotton package 2. To be packed in cartons or wood case 3. Use glass tape to seal cartons, or pin tight the wood case with nails. 4. Deliver out by DHL, FEDEX Or according to the customer‘s requirement. |

| Lead time of first samples | Around 4~7weeks |

| Other | 24 hours instant and comfortable customer service. |

| Shipping status notification during delivery. | |

| Rhipping status notification during delivery. |

About Us

Howe Mold was founded in 2010 to produce top class injection molds for the plastics industry. This company has an extensive background in building tools for the electronics, medical, computer, agricultural, automotive, and communications industries. Our customers turn to us to design and build various types of steel and aluminum, single or multi-cavity, molds for injection, structural foam, rim, blow, gas assist and structural web processes. We also design and build aluminum injection molds for limited production runs.

Today we serve customers in the computer, automotive, medical, material handling, electronics, and pet industries.

Specializing in three main areas:

Manufacture of custom prototype and production injection molds from

your part data to a complete mold in just weeks.

Rapid turnaround mold repairs, which allow you to get your tools

back into production quickly.

High quality machining, grinding, CNC machining, EDM and CNC EDM.

How to order from Howe?

1. According to 3D drawing or samples for quotation.

2. Including the price of moulds, moulds sizes, material for cores

& cavities, weight of product, part cost, payment, moulds lifetime,

delivery, etc.

3. After the customer confirming the mould design and quotation.

4. Confirm drawing, start to do DFM,mold flows and mold detail

agreed with the customer, start production.

5. Every week we will feedback to the customer a mold

progress(picture).

6. We provide the moulds test samples for confirmation(about 10-15

piece), then, get your signature sample ,mass production.

7. Wooden case for moulds, cartons for parts ,or as your

requiretment.

8. Deliver goods by air or by sea.

|