| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Multi Cavity Injection Moulding |

|---|---|

| Brand Name: | Custom LOGO |

| Model Number: | HW-638 |

| Certification: | ISO9001 |

| Place of Origin: | China |

| MOQ: | 1set |

| Price: | 2000-10000USD |

| Payment Terms: | T/T , Paypal |

| Supply Ability: | 40sets/month |

| Delivery Time: | 25-40days |

| Packaging Details: | wood carton, as customer requested |

| Name: | Plastics injection moulding |

| Life Time: | 300k~1000k Cycles |

| Surface Requirement: | Smooth, Polishing, Painting, SandBlasting, Electroplate, Silk-screen, Laser Etching, Anodizing,Brushing |

| Plastic Material: | ABS,PMMA,PA66,PETS,PC,TPU,POM,PBT, ect. |

| Mould Base type: | LKM, FUTA, HASCO, DME, TSMP, Or as per customer’s requirement. |

| Hardness of the steel: | 20~60 HRC |

| Process: | CNC Turning, Drilling, Milling, Punching..... |

| Mold cold runner: | 1*1,1+1,1*2,1+1+1,etc |

| Sea Port: | SHEN ZHEN port |

Single & Multi Cavity Plastics Injection Mould With S136 Steel Material

Professional Custom 1000k lifecycle Plastic Injection Mold for Plastic Parts

We offer design,mold build, injection molding, mold repair, tool and die, wire/sink EDM. Our complete portfolio provides you with a high quality resource supported by on-time delivery at a competitive price. Please provide your e-mail contact information, and I will be glad to send you information on our manufacturing capabilities.

| Name | Custom made plastic parts Injection moulding |

| Type of plastic mold | 3-plate mold,2-plate mold |

| Mold base | LKM 50 standard mould base or Self-made |

| Mold runner | Hot/Cold Runner |

| Base material | P20,P20H,718,718H,738,738H,2316,M300,S136,S136H,NAK80,CR12,CR12MOV,SKD11,DF-2,SKS3,D2,SLD,DC53,H13,SKD61,2344,8407,HD,8418,FDAC,M2,SKH-9 ,SKH-51,M35,M42,ASP23 |

| Mold Cavity | 1*1,1+1,1*2,1+1+1,etc |

| Diameter | 5-1000mm,or customized |

| Product Material | ABS, PA, PA66+30GF, PBT, PC, POM, PP, PE, PMMA,PVC,TPE,TPU etc |

| Color | White,black,green,nature,blue,yellow,etc |

| Treatment | S45C Pretreat>25Hrc,And Nitriding |

| Inserts(cavity and core) | H13, 1.2344, 1.2738, 1.2083, 1.2311, NAK80 or the material you required. |

| Gate type | Side gate,Sub gate,Pin point gate,Edge gate etc |

| Shape | Sheet, rod, tube, gear, pulley, guide rail, or as per your drawing |

| Ejection system | Stripper plate,Lifter,Push bar,Ejection pin etc |

| Design software | Pro/E,UG,Catia,Woodwork,Moldflow,AutoCad |

| Mold of steel suppliers | FINKL,Assab,DAIDO,LKM,Buderus |

| Hot Runners suppliers | Synventive,YUDO,INCOE,HASCO,DME,MOLDMASTER,HRS,DELACHAUX,SINO |

| Certification | ISO9001,SGS,Test Report,RoHS |

| Lifetime | >300 Thousand Times |

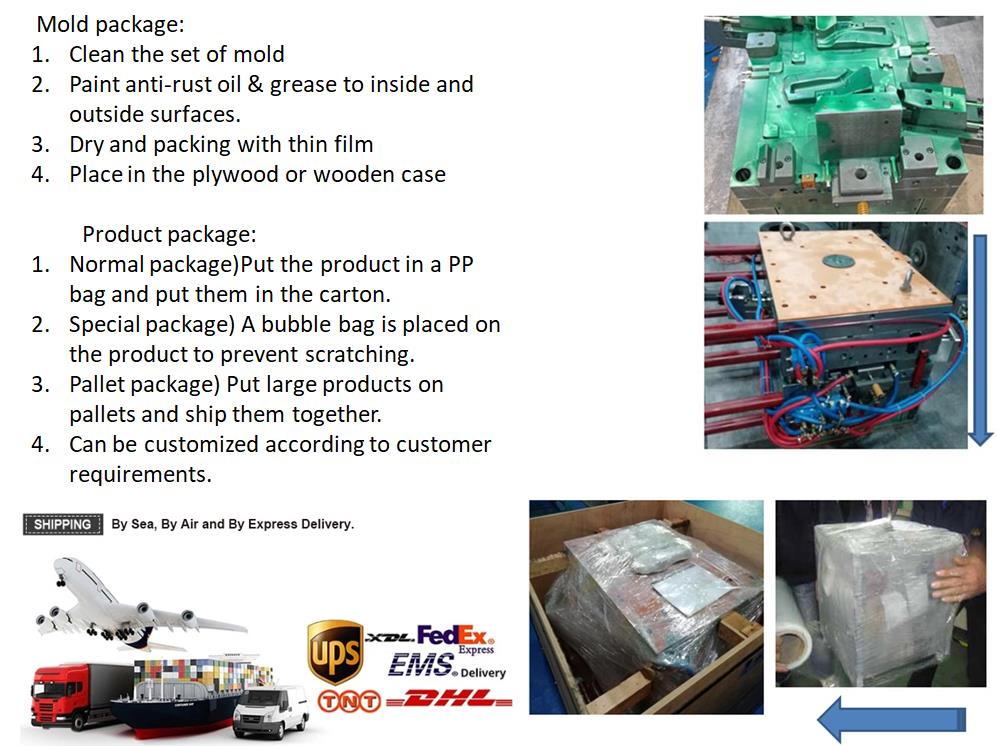

| Shipping Packing | Wood case or carton box 1. With plastic bag, with pearl-cotton package 2. To be packed in cartons or wood case 3. Use glass tape to seal cartons, or pin tight the wood case with nails. 4. Deliver out by DHL, FEDEX Or according to the customer‘s requirement. |

| Lead time of first samples | Around 4~7weeks |

| Other | 24 hours instant and comfortable customer service. |

| Shipping status notification during delivery. | |

| Rhipping status notification during delivery. |

About Us

Howe Mold was founded in 2010 to produce top class injection molds for the plastics industry. This company has an extensive background in building tools for the electronics, medical, computer, agricultural, automotive, and communications industries. Our customers turn to us to design and build various types of steel and aluminum, single or multi-cavity, molds for injection, structural foam, rim, blow, gas assist and structural web processes. We also design and build aluminum injection molds for limited production runs.

Today we serve customers in the computer, automotive, medical, material handling, electronics, and pet industries.

Specializing in three main areas:

Manufacture of custom prototype and production injection molds from

your part data to a complete mold in just weeks.

Rapid turnaround mold repairs, which allow you to get your tools

back into production quickly.

High quality machining, grinding, CNC machining, EDM and CNC EDM.

Customer Visiting

Packing and Shipping

d. Express (Alibaba express, DHL, UPS, FEDEX, TNT, EMS)

|