| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Sondex Spare Parts |

|---|---|

| Brand Name: | M&C |

| Model Number: | S4A |

| Certification: | ISO SGS FDA |

| Place of Origin: | Jiangsu, China (Mainland) |

| MOQ: | Negotiation |

| Price: | Negotiation |

| Payment Terms: | L/C, D/P, T/T, MoneyGram |

| Supply Ability: | 50000PCS/MONTH |

| Delivery Time: | 5-8 work days |

| Packaging Details: | Standard Export Carton,Wooden Case,Plywood |

| Product Name: | Heat Exchanger |

| Apply mechanical: | Chemical and mechanical |

| Structure: | Plate Heat Exchanger |

| Application: | Liquid to liquid hert exchanging |

| Dimension: | centre to centre: 381mm*70mm |

| Transfer Area: | 0.04㎡ |

| Company Info. |

| Jiangyin M&C Heat Parts Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

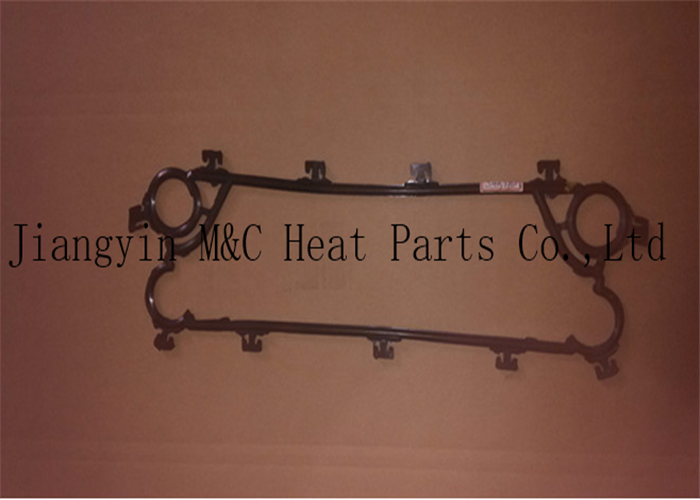

Equal With Sondex S4A Plate Heat Exchanger Gasket PHE Spare Parts

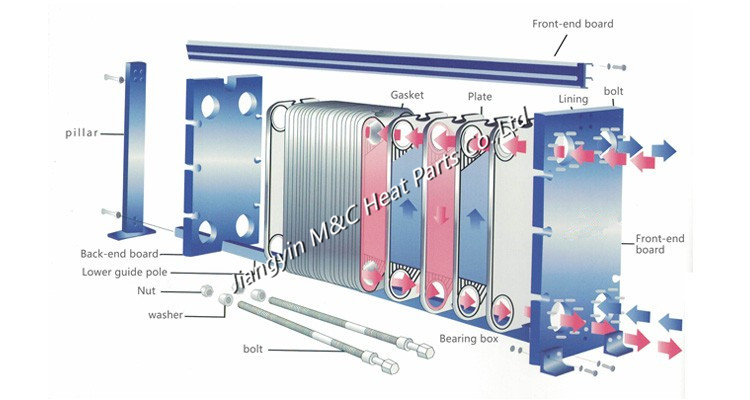

The plate heat exchanger consists of a pack of corrugated metal plates with portholes for the passage of the two fluids between which heat transfer will take place. The plate pack is assembled between a fixed frame plate and a movable pressure plate and compressed by tightening bolts. The plates are fitted with a gasket that seals the interplate channel and directs the fluids into alternate channels. The number of plates is determined by the flow rate, physical properties of the fluids, pressure drop, and temperature program. The plate corrugations promote fluid turbulence and support the plates against differential pressure. The frame plate and the pressure plate are suspended from an upper carrying bar and located by a lower guiding bar, both of which are fixed to a support column. Connections are located in the frame plate or, if either or both fluids make more than a single pass within the unit, in the frame and pressure plates.

| PLATE MATERIAL | SS304, SS316, 254SMO, 904L, C276, Titanium, Nickel, Incoloy825 |

| PLATE THICKNESS | 0.5mm, 0.6mm, 0.7mm, 0.8mm, 1.0mm |

| GASKET MTERIAL | EPDM, NBR, HNBER, HEPDM,FKW |

| GASKET ASSEMBLY | Clip on, Lock in, fasten, Glued |

| FRAME MATERIAL | Carbon steel, Stainless steel, Stainless steel coat |

| NOZZLE | Flange, Rubber insert, Metal insert, Thread, Clamp |

| CONNECTION SIZE | DN15~DN500 |

| CONNECTION STANDARD | Custiomized |

| COLOR | Custiomized |

| APPLICATION | HVAC, Power, Suger, Marine, Chemical, etc |

Plate Heat Exchanger Construction

A plate heat exchanger is a type of heat exchanger that uses metal plates to transfer heat between two fluids. It is composed of fixed pressure plate, flexible pressure plate, top and bottom guid bars, back post, support foot, heat exchanger plate, gasket, roller, tightening bolt, nut, lock wahser and frame foot.It has a major advantage over a conventional heat exchanger in that the fluids are exposed to a much larger surface area because the fluids are spread out over the plates. It is the most efficient type of heat exchanger with its low cost, flexibility, easy maintenance, and high thermal tranfer. We offer competitive heat exchanger solutions that surpass other OEM in performance, maintenance, and economy. The models we provide can replace the world famous manufacturers.

Material of PHE gasket and plate

M&C Heat Exchanger include Plate Heat Exchanger, Brazed Heat Exchanger, Heat Exchanger Spare Parts,and the material of gasket and plate are as follows:

| Gasket Material | Temperature(℃) | Fluid |

| Viton/FKM | -5 ---------+180 | Acid,Alkali Fluid |

| HNBR | -15--------+160 | High-temperature mineral water/oil, High-temprature water |

| NBR | -15--------+110 | Water,Sea water, Mineral smoke water |

| EPDM | -25-------- +170 | Hot water, steam,Acid, Alkali |

| Plate Material | Fluid |

| Hastelloy (C276,D205,B2G) | Concentrated sulfuric acid, Hydrochloric,Phosphoric acid |

| Titanium | Sea water,Salt water, Salt compounds |

| Nickel | High-emperature, high-concentration caustic soda |

| 20 Cr,18Ni6Mo(254SMO) | Dilute sulfuric,Aqueous salt solution, Inorganic water solution |

| Stainless Steel (AISI304,AISI316) | Water,Steam,Lubricants |

|