| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Reverse Dutch Weave Wire Mesh |

|---|---|

| Brand Name: | Xingkuan Tech |

| Model Number: | Continuous Filter Belt |

| Certification: | Bv ,sgs , ce , Iso |

| Place of Origin: | Hebei ,China |

| MOQ: | 1 roll |

| Price: | Negotiate |

| Payment Terms: | T/T, L/C, Western Union |

| Supply Ability: | 5000SQM/Week , a large of stock ready whole year . |

| Delivery Time: | 1-7 workingdays |

| Packaging Details: | waterproof paper , wooden case or carton , or as per customer request ! |

| Item: | Stainless Steel Continuous filter belt screen |

| Material: | stainless steel 201,302,304,304A,316 ,Iron ,Copper clad steel |

| Mesh count: | 72x15 , 260x40,132x17,152x24,180x16,120x16 , 110x15,110x8,110x17 ,etc |

| Height: | 85mm ,97mm,120mm,127mm,130mm,130mm,135mm,140mm,150mm,200mm,308mm ,etc |

| Length: | 10m,15m,20m ,30m , 40m, 80m ,etc |

| Delivery time: | standard size we have stock , normally 1-3 working days |

| Sample: | Free sample for small size |

| Edge: | common edge is rubbed edge , or plasma welding edge |

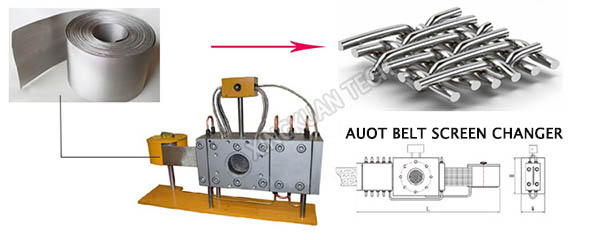

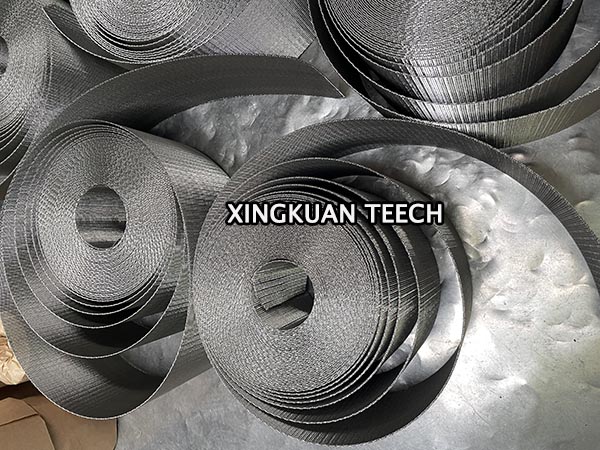

Continuous Belt Screens for extrusion process without interrupting

Descriptions :

Continuous Belt: As a screen roll indexed by either a hydraulically activated screen puller or process-flow pressure exerted on a melt plug. In both cases time and screen differential pressure controls the screen index.Continous belt is woven through machine by the weaving style of reverse dutch weaving to tend not to leak or jam and filters out impurities in the polymer extrusion process—without interrupting the process when a dirty screen needs to be changed.it's used in melt filtration processes where debris can clog up screens in a very short time and process disruptions are costly. Extrusion process that employ continuous screen belt include pipe and profile, film and sheet, compounding, resin production, blow molding, nonwovens, and specialty material.

Quick Detail :

Specifications:

Below is only Part of standard specification , we can make as per request also

| Mesh Size | Wire diameter | Fineness filtering | Weight | Width | Length |

| (warp/inch × weft/inch) | (mm) | (micron) | (kg/m2) | (mm) | (m) |

| 48 × 10 | 0.5x0.5 | 400 | 3.63 | 60-420 | 10-40(80) |

| 63 × 18 | 0.4x0.60 | 220 | 4.14 | 60-420 | 10-40(80) |

| 72 × 15 | 0.45x0.55 | 250 | 4.78 | 60-420 | 10-40(80) |

| 100 × 16 | 0.35x0.45 | 190 | 3.87 | 60–420 | 10-40(80) |

| 107 × 20 | 0.24x0.60 | 210 | 3.34 | 60-420 | 10-40(80) |

| 120 × 16 | 0.35x0.45 | 180 | 4.49 | 60-420 | 10-40(80) |

| 132 × 17 | 0.32x0.45 | 170 | 4.24 | 60-420 | 10-40(80) |

| 152 × 24 | 0.27 × 0.4 | 160 | 3.73 | 60–420 | 10-40(80) |

| 160 × 17 | 0.27 ×0.45 | 160 | 2.02 | 60-420 | 10-40(80) |

| 170 × 18 | 0.27 ×0.45 | 160 | 4.01 | 60-420 | 10-40(80) |

| 171 × 46 | 0.15x0.30 | 130 | 2 | 60-420 | 10-40(80) |

| 180 × 20 | 0.27x0.45 | 170 | 4.29 | 60–420 | 10-40(80) |

| 200 × 40 | 0.17x0.27 | 120 | 2.17 | 60-420 | 10-40(80) |

| 240 × 40 | 0.15x0.25 | 70 | 1.98 | 60-420 | 10-40(80) |

| 260 × 40 | 0.15x027 | 55 | 2.19 | 60-420 | 10-40(80) |

| 290 × 76 | 0.09x0.19 | 40 | 1.27 | 60-420 | 10-40(80) |

| 300 × 40 | 0.15x0.25 | 50 | 2.31 | 60–420 | 10-40(80) |

| 300 × 80 | 0.15 × 0.2 | 35 | 2.49 | 60-420 | 10-40(80) |

Applications :

Notice :

|