| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Duct Production Line |

|---|---|

| Brand Name: | PSL |

| Model Number: | PSL-1.2x1300 |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | USD10,000.00 - USD50,000.00 |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 5 sets per month |

| Delivery Time: | 45-60days |

| Packaging Details: | naked in container |

| Machine name: | CNC Duct Auto Line-V |

| Condition: | New |

| Mainbody: | Sheet & tube metal welded structure |

| Applicable Industries: | Building Material Shops, Manufacturing Plant, Energy & Mining |

| Control mode: | CNC system PLC control |

| Operation: | Automatic |

| Producing materials: | Galvanized sheet metal, stainless steel plate |

| Industry: | Construction Engineering, air conditioning, ventilation duct |

| Max Width: | 1250mm/1500mm |

| Core Components: | PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear |

| Sheet Thickness: | 0.5-1.2 mm |

| Dimension(L*W*H): | 18500 x 2000 x 1500 |

| voltage: | 220V/380V/415V/440V, 50HZ/60HZ, customized |

| Color: | Gray black+yellow, Blue+white, or customized |

| After-sales Service Provided:: | Engineers available to service machinery overseas; technology support online because of Covid-19 |

Ventilation industry CNC Duct Auto Production Line 5 V

Feature of Duct manufacture auto-line V:

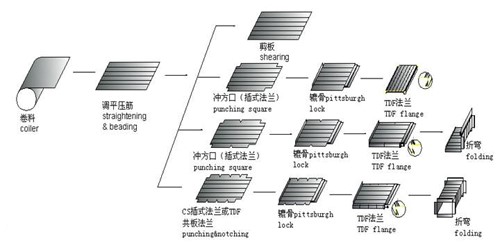

It can make TDF flange / angle steel flange. The capacity of day is 1000-2500 square meters. Users can only input sizes of duct you need, then this auto line will automatically complete unwinding, leveling, punching, shearing, Pittsburgh lock forming, TDF/Angle steel flange forming and C-cleat flange and folding into rectangular ducts.

Features:

● Liner structure;streamline in production and small occupation;

● All coilers being driven by the speed adjustable independent frequency converter motor ;

● with the material processing saving mode, users can reduce the waste

of sheet metal significantly to less than 20mm per material coiler

● with the feature of servo motor driven in folding process and

accurate positioning, it has the obvious advantage, especially when

make “口”

shaped duct .

● only need one worker to operate the machine , its production

capacity can reach 2000 M3 each 8 hours

● the speed of each part can be adjusted as users’request.

● Support production data records export and print function (optional)

Main imported configuration:

● Beijing Huade with hydraulic system

● Japan Omron encoder

● Japan MITSUBSHI controller FX3GA-40MR-CM

● Taiwan Hiwin linear guide

● Schneider electrical system

BASIC EQUIPMENTS:

● Two electric feeding coil candles (2900*1900*950 mm)

● A material supporting frame

● A main machine auto line II, including leveling, beading, punching and cutting.

● A movable high-speed Pittsburgh lock forming machine

● A duplex angle steel flange forming machine

● A duplex TDF flange forming machine

● Three servo motors power material feeder

● Three Servo Drivers

● A hydraulic folding machine

● A CNC System PLC controller

Technical details:

| Model No. | PSL5-1.2x1300 |

| Max Coil Width | 1300mm |

| Thickness Range | 0.4-1.2mm |

| Speed | 0-18m/min |

| Power | 24.5 kw |

| dimensions | 18.5*2.8*1.5m |

| Shearing Tolerance | ±0.5mm |

| Diagonal Tolerance | ±0.5mm |

| Weight | 10 ton |

|