| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Vibration Table Testing Equipment |

|---|---|

| Brand Name: | LABTONE |

| Model Number: | EV450 |

| Certification: | SGS CE / ISTA / ISO |

| Place of Origin: | Dongguang, China |

| MOQ: | 1 Set |

| Price: | Negotiable |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 15 Sets / Month |

| Delivery Time: | 45 Working Days |

| Packaging Details: | Plywood Case with Vacuum Packing |

| Sine Force Peak: | 5000kg.f |

| Random Force: | 5000kg.f |

| Frequency Range: | DC-3000 Hz |

| Software: | Sine, Random, Shock |

| Control Computer: | Acer |

| Displacement: | 100mm p-p |

| Payload: | 500kg or more |

| Head Expander: | Magnesium Alloy |

| Company Info. |

| Labtone Test Equipment Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Air Cooling Shock And Vibration Test Equipment For Package Test ISO-13355

Vibration testing simulates the vibration conditions that a product might experience during its lifetime but under a controlled and repeatable test environment. Vibration tests are conducted in an accredited vibration testing lab to ensure that finished products can perform safely during operation or transit and to avoid unexpected performance issues or early failure during use. Because products spend their lifetime in different environments and these environments exhibit unique vibration profiles, our vibration testing services are tailored to fit each unique environment with specific vibration control profiles.

Vibration Shaker System Specifications: EV450

| Shaker Specifications A50F44 | |

| Peak Sine (Pk) | 5000Kg.f peak (50KN) |

| Random (RMS) | 5000Kg.f r.ms (50KN) @ISO5344 |

| Shock (Pk) | 10000Kg.f peak (100KN) @6ms |

| Usable Frequency | 1~2500Hz |

| Maximum Displacement (p-p) | 100mm (4inch) intermittence, 80mm (3inch) continuous |

| Max. velocity | 2m/s |

| Max. acceleration | Sine:83g (813 m/s2);Random: 60g (588 m/s2) |

| Vertical Load Support | 500 kg |

Body Suspension Natural Frequency (Thrust Axis) | Less than 2.5 Hz |

| Armature Diameter | Ф440 mm |

| Armature Weight | 50 kg |

Fundamental Resonance Frequency (Bare table) | 2,100 Hz (nom.) +/- 5% |

Load Attachment Points (Standard) | 16 stainless steel M10 Inserts |

| Stray Flux Density | <10gauss |

| Allowable partial force | 1000.N.M |

| Shaker dimensions | 1670L x 1150D x 1300H mm |

| Weight of Shaker | About 4600Kg |

| Power Amplifier Specifications LA50K | |

| Rated Output Capacity | 50KVA |

| Signal to Noise Ratio | Greater than 65 dB |

| Amplifier Efficiency | Greater than 90% |

| Amplifier Overall Dimensions | 650mmL×920mmD×2100mmH |

| Weight of Amplifier | About 560Kg |

| Interlock Protection | ●Input Over/Under Voltage ●Logic Fault ●Output Over Voltage/Current ●Control Power ●External ●Shaker Oil Pressure ●Module O/T ●Shaker Temp ●Shaker Travel |

The model selection of the vibration test system has the following steps:

1. Determine the test frequency range and limit peak motion

(acceleration, velocity and displacement) according to the test

conditions.

2. Determine the mass (DUT) of the item under test and the dimensions of the mounting surface required to bolt the DUT to

a shaker table with its center of gravity (CG) over the table’s

center. This may require use of a head expander and/or other

mounting fixture. Determine the mass of such additional hardware

including all mounting fasteners.

Look at the shaker specifications for the test system. Verify that the mass of the part under test and any mounting fixture is less than the maximum static load rating of the shaker. Verify that the component under test (or its mounting hardware) can be bolted to the shaker armature or head expander. Add the effective armature mass and expansion head mass to the mass of the object under test as well as the mass of any mounting clamps and fasteners and the mass of any accelerometers mounted on the object under test -- this is the total moving mass the shaker must move during the test. Multiply the total moving mass by the acceleration determined in step 1 to calculate the force required. Verify that the test and DUT required to determine the test frequency range, force, peak acceleration, peak velocity, and peak displacement is less than the corresponding performance rating of the selected shaker system. If this is true, the shaker chosen is acceptable. If not, a more powerful shaker is required.

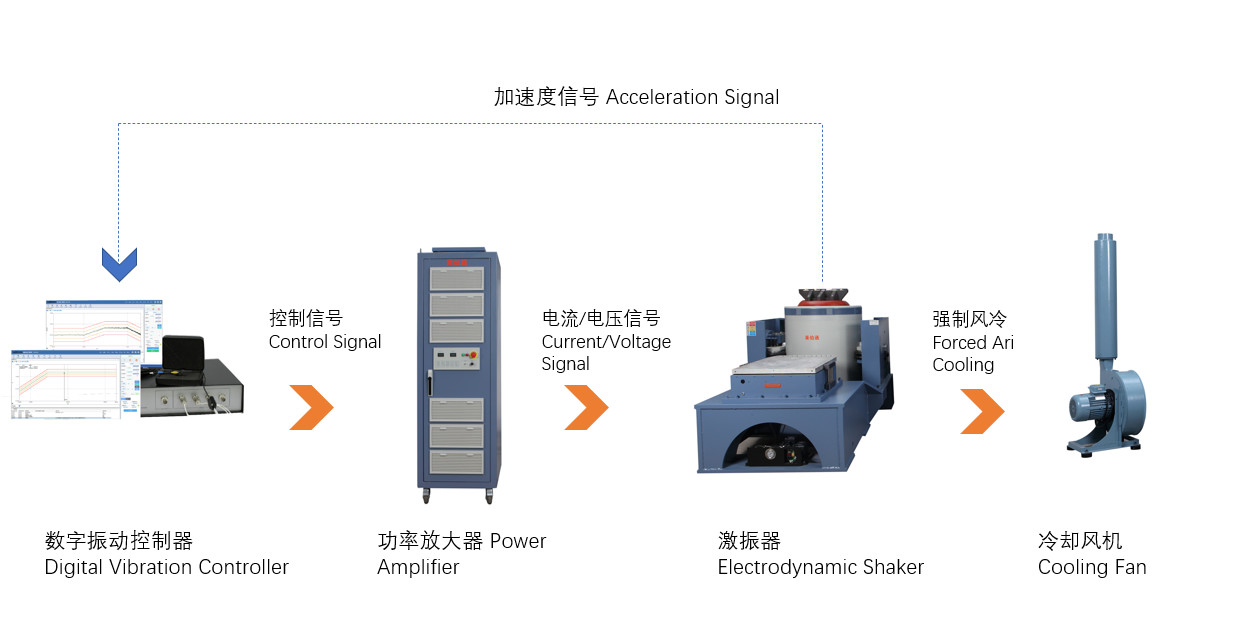

Working Principle:

Application:

Services:

|