| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Industrial Filter Press |

|---|---|

| Brand Name: | Yuwei |

| Model Number: | YWXAZ |

| Certification: | CE / ISO |

| Place of Origin: | China |

| MOQ: | 1 |

| Price: | Negotiable |

| Payment Terms: | T/T, L/C, Western Union |

| Supply Ability: | 500 Unit per Month |

| Delivery Time: | 10-20 work days |

| Packaging Details: | Bubble Wrap/ Wooden Case |

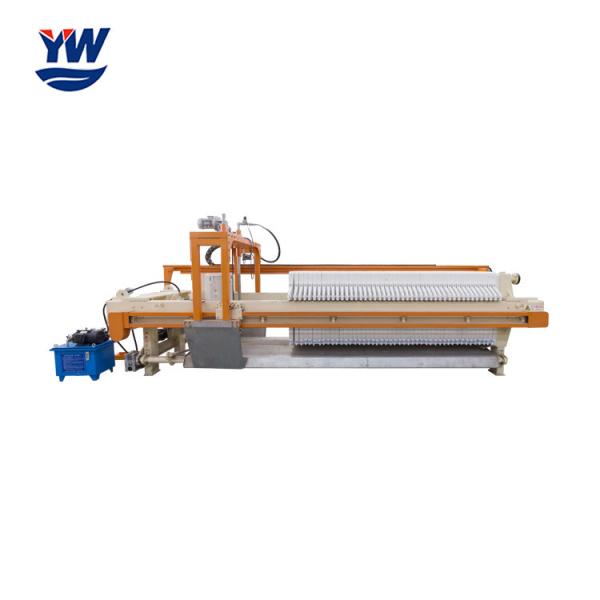

| Name: | Chamber Filter Press |

| Material: | Carbon Steel |

| Plate Material: | PP |

| Plate Shifting: | Auto |

| Working Pressure: | 0.6 MPa |

| Closing Pressure: | 18 Mpa |

| Power: | 380V/50HZ/3PHS |

| Control: | PLC |

Product description

The Industrial Filter Press for Mud Sewage Treatment is a filter chamber composed of a filter frame. Under pressure, it uses a filter medium to separate solids from liquids. The invention adopts the process molding, has high strength, light weight, corrosion resistance, acid and alkali resistance, non-toxic and tasteless, reasonable design, simple structure, reliable performance, convenient use and easy maintenance, and is suitable for solid-liquid separation process in chemical, petroleum, metallurgy, pharmaceutical, food, environmental protection and other industries. It is widely used and adaptable.

Advantages of Industrial Filter Press for Mud Sewage Treatment:

Specification

| Model | Filter Area | Plate size | Filter chamber volume | Plate NO. | Filtration pressure | Motor power | Dimensions L*W*H(mm) |

| AZ30/870−30U | 30 | 870*870 | 460 | 23 | 0.6 | 2.2 | 3180*1400*1230 |

| AZ40/870−30U | 40 | 595 | 30 | 3570*1400*1230 | |||

| AZ50/870−30U | 50 | 748 | 38 | 4110*1400*1230 | |||

| AZ60/870−30U | 60 | 902 | 46 | 4550*1400*1230 | |||

| AZ70/870−30U | 70 | 1056 | 54 | 4990*1400*1230 | |||

| AZ80/870−30U | 80 | 1210 | 62 | 5430*1400*1230 | |||

| AZ50/870−30U | 50 | 1000*1000 | 736 | 28 | ≥0.6 | 4 | 4040*1500*1400 |

| AZ60/870−30U | 60 | 889 | 34 | 4460*1500*1400 | |||

| AZ70/870−30U | 70 | 1041 | 40 | 4760*1500*1400 | |||

| AZ80/870−30U | 80 | 1193 | 46 | 5120*1500*1400 | |||

| AZ100/870−30U | 100 | 1475 | 57 | 5780*1500*1400 | |||

| AZ120/870−30U | 120 | 1777 | 69 | 6500*1500*1400 | |||

| AZ100/1250−30U | 100 | 1250*1250 | 1468 | 36 | ≥0.6 | 4 | 5020*1800*1600 |

| AZ120/1250−30U | 120 | 1746 | 43 | 5470*1800*1600 | |||

| AZ140/1250−30U | 140 | 2063 | 51 | 5990*1800*1600 | |||

| AZ160/1250−30U | 160 | 2341 | 58 | 6450*1800*1600 | |||

| AZ180/1250−30U | 180 | 2619 | 65 | 6905*1800*1600 | |||

| AZ200/1250−30U | 200 | 2896 | 72 | 7360*1800*1600 | |||

| AZ220/1250−30U | 220 | 3214 | 80 | 7880*1800*1600 | |||

| AZ250/1250−30U | 250 | 3650 | 91 | 8600*1800*1600 | |||

| AZ200/1500−35U | 200 | 1500*1500 | 2998 | 49 | ≥0.6 | 7.5 | 6400*2200*1900 |

| AZ250/1500−35U | 250 | 3594 | 61 | 7225*2200*1900 | |||

| AZ300/1500−35U | 300 | 4347 | 74 | 8130*2200*1900 | |||

| AZ350/1500−35U | 350 | 5043 | 86 | 8950*2200*1900 | |||

| AZ400/1500−35U | 400 | 5796 | 99 | 9880*2200*1900 | |||

| AZ450/1500−35U | 450 | 6492 | 111 | 10690*2200*1900 | |||

| AZ500/1500−35U | 500 | 7187 | 123 | 11560*2200*1900 | |||

| AZ600/2000−40U | 600 | 2000*2000 | 8926 | 85 | ≥0.6 | 15 | 11100*3000*2500 |

| AZ700/2000−40U | 700 | 10380 | 99 | 12200*3000*2500 | |||

| AZ800/2000−40U | 800 | 11210 | 107 | 13350*3000*2500 | |||

| AZ900/2000−40U | 900 | 13290 | 127 | 14500*3000*2500 | |||

| AZ1000/2000−40U | 1000 | 14740 | 141 | 15600*3000*2500 |

Application

Automatic Chamber filter press is widely used for solid-liquid

separation in petrochemical, metallurgy (gold, silver, copper,

iron, zinc, rare earth, etc.), oil (edible oil, light oil,

glycerin, machine oil, vegetable oil, etc.), ceramics (bentonite,

activated clay, clay, etc.) and other industries.Sludge treatment

is a process that enables sludge to be concentrated, conditioned,

dehydrated, stabilized, desiccated or incinerated to reduce,

stabilize and make it harmless. The higher the degree of sewage

treatment, the more sludge residue will be produced to be treated.

Before sludge treatment, we must first understand the

classification of sludge to determine the method of sludge

treatment:

|