| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | IBC Bin Blender |

|---|---|

| Brand Name: | WKS |

| Model Number: | 1000L |

| Certification: | CE |

| Place of Origin: | CHINA |

| MOQ: | 1 |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Supply Ability: | 10 sets per month |

| Delivery Time: | 20-40 working days |

| Packaging Details: | normally it is packed in the plywood case, or loaded directly in the container after film wrapping |

| Name: | IBC Bin Blender |

| Control mode: | PLC touch screen |

| Model: | 1000L |

| Mixing speed: | 3-10rpm |

| Max. volume: | 1000L |

| Load volume: | 800L |

| Load weight: | 500kg |

| Power: | 7kW |

| Weight: | 2000kg |

| Material: | 304 or 316L stainless steel |

Lifting Hopper IBC Bin Mixer for Nutraceuticals Pharmaceutical Chemical Powders

IBC Bin Blender

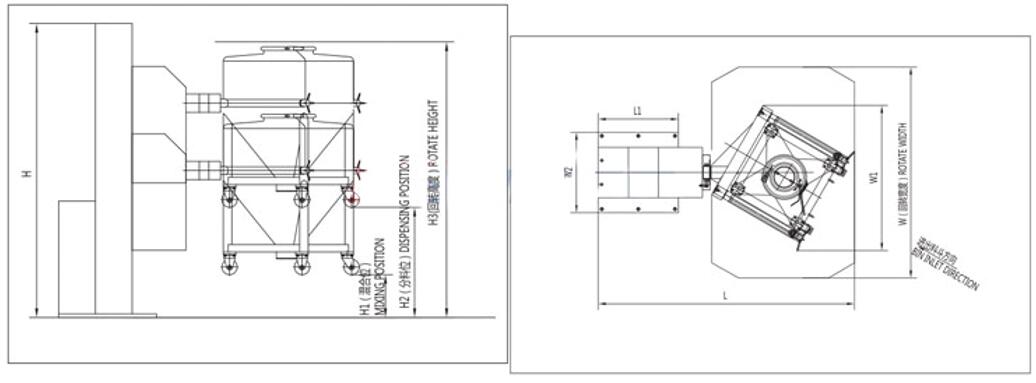

This machine is our company widely absorb, digest foreign advanced technology, combined with national conditions R & D success of the new models. Reasonable structure, stable performance, easy operation, no dead ends, no exposed screws. The rotor (mixing hopper) is at an angle of 30 ° to the axis of rotation. The material in the mixing hopper is tilted along with the rotor, and the tangential movement along the bucket wall produces a strong inversion and high-speed tangential motion to achieve the best The mixing effect. Using PLC automatic control, and set the infrared safety devices and anti-misoperation device out of the butterfly valve to ensure production safety. Materials can be in the same container through a different block, do not need frequent transfer, feeding and other procedures. Effectively control the dust and cross pollution, reduce the loss of materials, control the material layer, optimize the production process, in full compliance with the GMP production requirements of drugs.

| Model | DTH50 | DTH100 | DTH200 | DTH300 | DTH400 | DTH500 | DTH600 | DTH800 | DTH1000 | DTH1200 | |

| W | 1400 | 1400 | 1800 | 2000 | 2100 | 2300 | 2400 | 2500 | 2700 | 2800 | |

| W1 | 1020 | 1020 | 1202 | 1306 | 1455 | 1530 | 1583 | 1730 | 1898 | 1888 | |

| W2 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 9o0 | 900 | |

| L | 2045 | 2045 | 2260 | 2457 | 2555 | 2595 | 2663 | 2800 | 3020 | 3150 | |

| L1 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 820 | 980 | |

| H | 2000 | 2000 | 2300 | 2300 | 2400 | 2500 | 2500 | 2500 | 2900 | 4250 | |

| H1 | 250 | 250 | 350 | 350 | 350 | 350 | 350 | 350 | 400 | 450 | |

| H2 | 750 | 750 | 750 | 750 | 750 | 750 | 750 | 750 | 900 | 1700 | |

| H3 | 1500 | 1500 | 1950 | 2150 | 2250 | 2400 | 2500 | 2600 | 2800 | 3100 | |

| Mixing speed | rpm | 3~20 | 3~20 | 3~20 | 3~20 | 3~20 | 3~15 | 3~15 | 3~15 | 3~10 | 3~8 |

| Maximum silo volume | L | 50 | 100 | 200 | 300 | 400 | 500 | 600 | 800 | 1000 | 1200 |

| Loading | L | 40 | 80 | 160 | 240 | 320 | 400 | 480 | 640 | 800 | 960 |

| Load weight | kg | 25 | 50 | 100 | 150 | 200 | 250 | 300 | 4o0 | 500 | 550 |

| Total power | kw | 3.7 | 3.7 | 4.4 | 5.2 | 5.2 | 5.2 | 5.2 | 7 | 7 | 7 |

| Total weight | kg | 600 | 700 | 800 | 900 | 1000 | 1200 | 1300 | 1600 | 2000 | 2200 |

Design

|