| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Valve Bag Making Machine |

|---|---|

| Brand Name: | Ounuo |

| Model Number: | ON-WSA |

| Certification: | CE |

| Place of Origin: | China |

| MOQ: | 1set |

| Price: | USD500,000-550,000 SET |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20 sets per month |

| Delivery Time: | 90 work days |

| Packaging Details: | standard packing |

| Sack width: | 300-600mm |

| Sack length: | 410-910mm |

| Bottom width: | 80-180mm |

| Bottom center distance: | 310-680MM |

| Speed: | 90-120pcs/min |

| Power: | 105kw |

| Equipment size: | 12m*7.5m*3m |

| Operating pressure: | 6-7bar |

| Company Info. |

| Zhejiang Allwell Intelligent Technology Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Tube Roller Feeding 25kg Hot Sales Block Bottom Valve Sacks|Cement Kraft Laminated Paper Sacks Making Machine

Valve bagging is when a bag is filled using a specialized machine. The machine uses a spout placed in or near the opening of the bag. A measured amount is placed in each bag. This can be done in a fully automated or semi-automated manner. This ensures consistency in quantity and minimizes lost product.

The benefits of these machines are numerous and span multiple

industries. The biggest benefit is the volume of bags that can be

filled and closed per hour. The output is significantly higher than

if done by an employee. This increase in output translates to

higher profit by filling orders more quickly. Businesses converting

to this method often find the cost of the machine is quickly

covered and a return on investment is recognized very soon.

1.Machine specification:

| I.Technical Parameter | |

| Sack width | 300-600 mm |

| Sack length | 410-910 mm |

Bottom width(B > 160 mm) | 80-180 mm |

| Bottom center distance | 310-680 mm |

| Main fabric cutting length | 510-1090 mm |

| Fabric width | 55-80cm |

| Coating Weight(15% PE, 85% PP) | 17-30 g/m² |

| Speed | 90-120 个/min |

| 2.Material Specification | |

| 2.1Tubular fabric requirement | |

| Material specification | 2.5-5 mm PP tapes |

| Fabric Weight | 55-80 g/m² |

| Coating Weight | 17-30 g/m² |

| Coating adhesion | Min. 8.1N/30mm |

| Width tolerance | ±7 mm |

Weight tolerance (fabric + coating) | ±3 g/m² |

| Over coating | Max. 5mm |

| 2.2Flat fabric for patches | |

| Fabric Weight | 55-80 g/m² |

| Coating Weight(15% PE, 85% PP) | 17-30 g/m² |

| Coating adhesion | Min. 8.1N/30mm |

| Width tolerance | ±3 mm |

Weight tolerance (fabric + coating) | ±3 g/m² |

Electrical,water,air requirement | |

| Power | 105 KVA |

Water consumption (Max 18°C, 4 bar) | 2m³/h |

| Operating pressure | 6-7 bar |

| Air consumption | 120 m³/h |

| Air compressor | Prepared by customer |

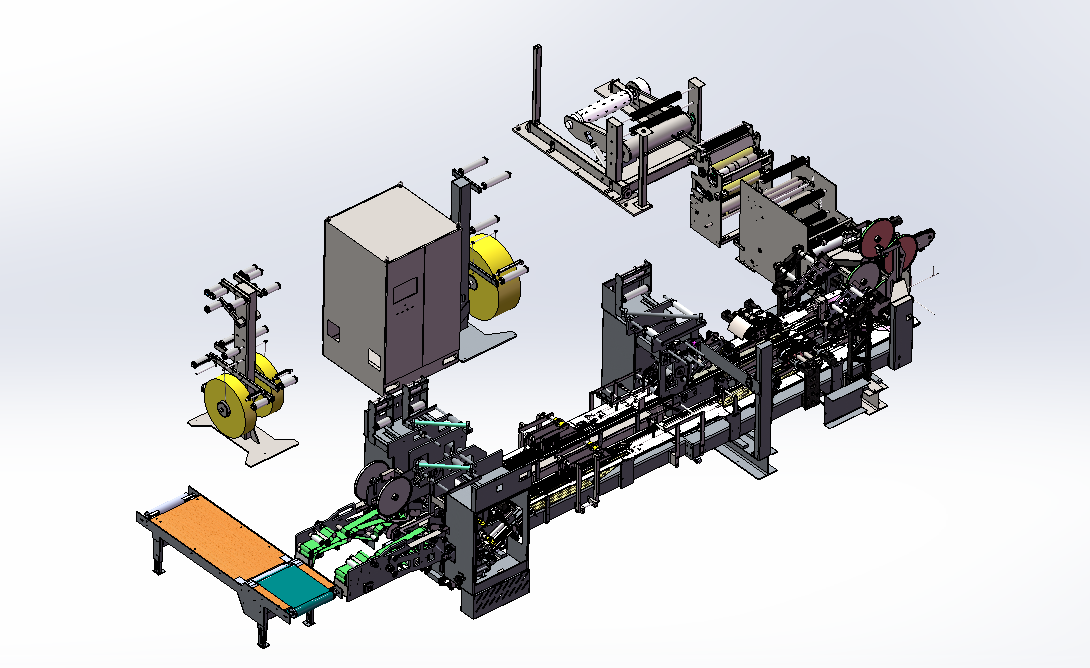

2.Machine Drawing

3.Where are woven sacks be used

Woven bags play an important role in reducing or preventing the detrimental effects of flood waters. They are widely used in the construction of dams, river banks, roads and railways. Woven polypropylene sandbags are widely used all over the world

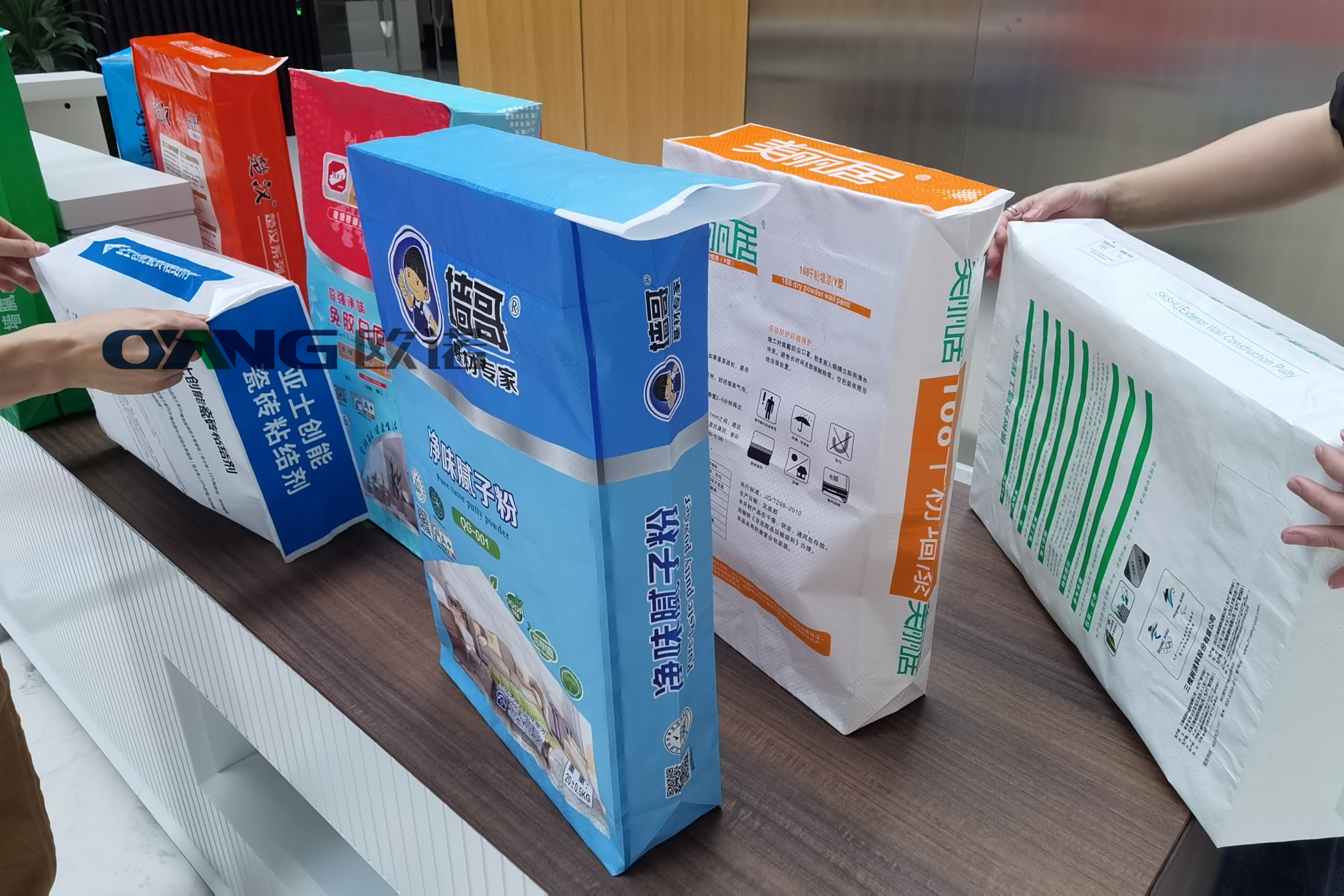

4.Valve sack bag samples

|