| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Ball Mill Media |

|---|---|

| Brand Name: | TENCAN |

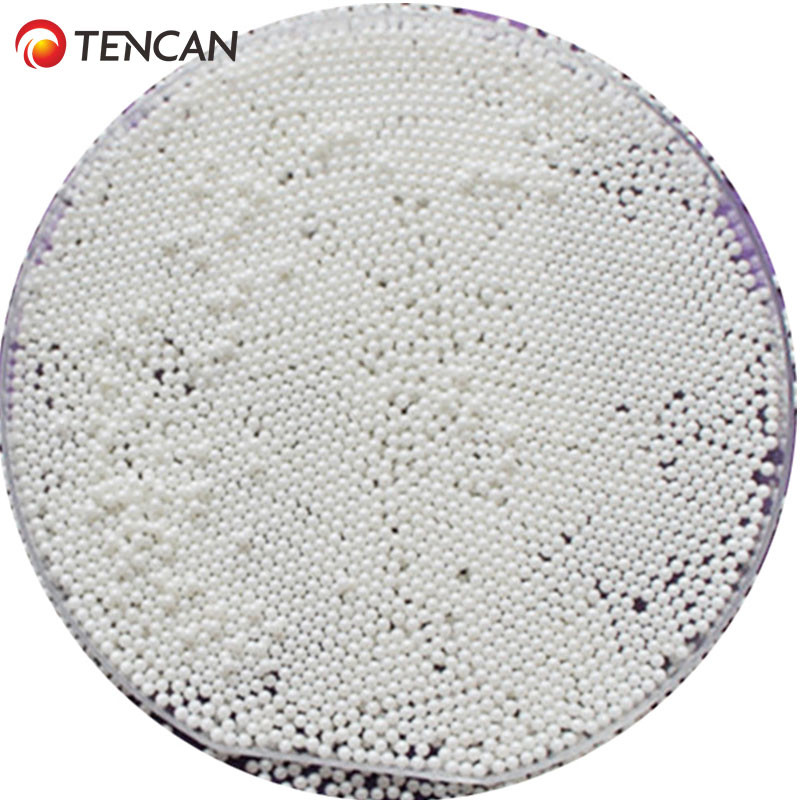

| Model Number: | 0.1, 0.3mm Diameter |

| Certification: | CE ISO |

| Place of Origin: | Hunan, China |

| MOQ: | 1 kg |

| Price: | Negotiable |

| Payment Terms: | T/T, Western Union, T/T |

| Supply Ability: | 2000kgs |

| Delivery Time: | 3-7 working days |

| Packaging Details: | Carton |

| Product Name: | Zirconia Balls For Ball Mill |

| Hardness: | 9.0 mohs |

| Material: | Zirconium Oxide |

| Color: | White |

| Packing: | Carton |

| Uasge: | For grinding & milling |

| Available Sizes: | 0.1mm, 0.3mm |

| Origin: | Hunan, China |

| Company Info. |

| Changsha Tianchuang Powder Technology Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

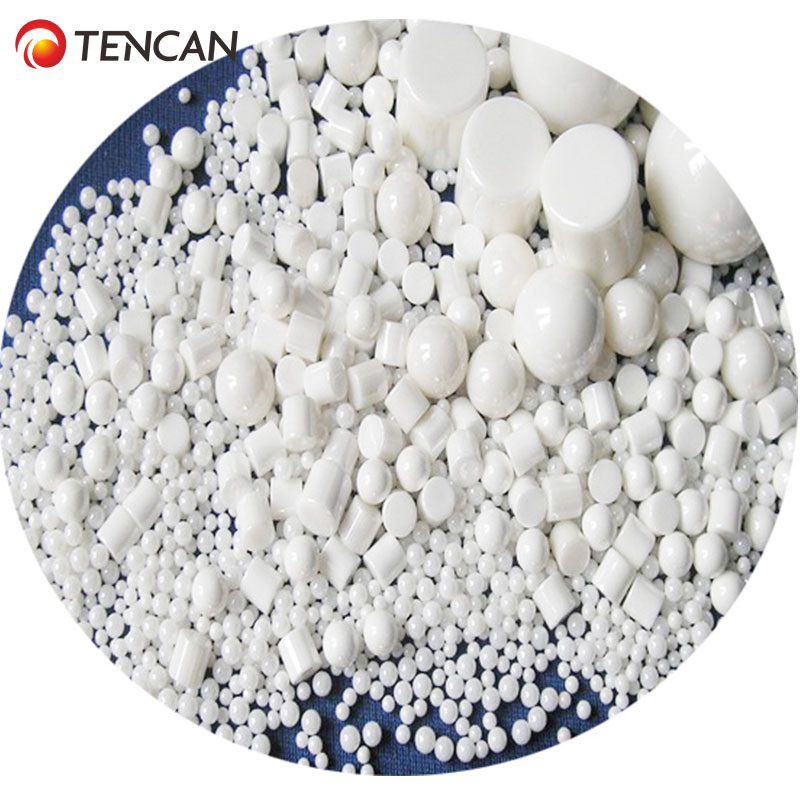

1-30mm Diameter High Quality Zirconia Mill Balls Best Grinding Media Without Any Impurity Contamination

Overview

Zirconia mill ball is also called zirconia grind ball, zirconia ceramic ball, zirconium bead, ultra-fine grinding media and zirconia mini bead. It has smooth and gloss surface like pearl, which is the most excellent among all grinding media.

Zircoia grind ball owns advantages of high hardness, high toughness and high density, good abrasion resistance, heat-resistance, corrosion-resistance, high stiffness, non-magnetic and electrical isolation. Its thermal expansion ratio is next to steel. Its hardness and strength can be hardly changed even under condition of 600℃.

Applications

Zircoia mill ball is used for grinding materials into ultra-fine

powder in wet and dry methods. It is commonly applied to the

following fields:

A. High strength and toughness products: magnetic material,

piezoelectric ceramics, dielectric ceramics

B. Prevent pollution: medicine, food, cosmetic and dyeing

industries.

C. Abrasion and corrosion resistant products: painting and coating,

printing ink, paper making, solar cell, and nonmetal industries.

D. Ceramics: electronics ceramics, refractory ceramics, structural

ceramics.

Features

1. High grinding efficiency: It has higher grinding efficiency

under some conditions.

2. Good fluidity: Smooth and gloss surface, lower abrasion compared

with other media.

3. Impact resistance and low abrasion: TZP zirconia ceramic mini

ball has good toughness, and it won’t be cracked and peeled under

high speed rotation and high concentration environment and its

abrasion ratio is only half of zirconium silicate beads.

4. Low using cost: Zirconia ball saves your costs greatly, such as

reducing media and equipment abrasion, saving electricity and labor

cost and so on.

Technical Data

| Technial Data of Zirconia Mill Balls for Ball Mill | |

| Components (%) | 94.8% ZrO2, 5.2% Y2O3 |

| Material | Zirconium Oxide |

| Density (g/cm3) | 6.05 |

| Hardness (mohs) | ≥9.0 |

| Bulk Density (g/cm3) | 3.6 |

| References About Grinding Medias & Materials | ||

| Materials of Grinding Media | Hardness (Mohs) | Features |

| Zirconia Balls | ≥9.0 | Super wear-resistance, without any impurity, corrosion & high temperature resistance. |

| Stainless Steel Balls | ≥6.0 | Wear-resistant, general corrsion resistance, high temperature resistance. |

| Agate Balls | ≥7.0 | Super wear-resistance, used for medicine,food and other materials which can not be contaminated with metal, corrosion, and high temperature resistance. |

| Alumina Balls | ≥8.5 | Wear-resistant, corrsion resistance and high temperature resistance. |

| Tungsten Carbide Balls | ≥9.0 | Super wear-resistance, without any impurity, corrosion & high temperature resistance. |

| Matching Solutions for Mill Jars & Balls | |||||

| Items | Agate Balls | Alumina Balls | Stainless Steel Balls | Zirconia Balls | Tungsten Carbide Balls |

| Agate Mill jar | √ | ||||

| Corundum Mill Jar | ▲ | √ | ▲ | ||

| Stainless Steel Mill Jar | √ | ||||

| Zirconia Mill Jar | ▲ | √ | |||

| Nylon Mill Jar | ▲ | √ | |||

| PTFE Mill Jar | √ | ▲ | |||

| Polyurethane Mill Jar | √ | ▲ | |||

| Tungsten Carbide Mill Jar | ▲ | √ | |||

| √ means: most suitable ▲ means: suitable | |||||

|