| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Automobile Engine Parts |

|---|---|

| Brand Name: | SJ |

| Model Number: | SJ7292405 |

| Certification: | TS16949,PED Certification |

| Place of Origin: | China |

| MOQ: | Negotiable |

| Price: | communication |

| Payment Terms: | T/T |

| Supply Ability: | 3000 to 10000 per month |

| Delivery Time: | 5 to 6 weeks |

| Packaging Details: | carton Box+ Wood Box |

| Material: | Alloy steel aluminum automobile engine assembly die casting |

| Inspection: | 100% Postion gauge check |

| Machining: | Precision CNC Machining, |

| Product name: | Automobile casting part manufacturing |

| Size: | Customised |

| Type: | Investment Casting |

Auto Parts Precision Die Casting Car Alloy Engine Housing Parts

Auto Parts Precision Die Casting Car Alloy Engine Housing

Ningbo Suijin System solutions in engine block casting

Flexibility of the size: All dimensions of crankcases can be

produced using the sandcasting method; from the small 3-cylinder

crankcase for passenger cars to the largest crankcase for trucks.

Flexibility of the geometry: The freedom of design for the cavities

in the crankcase is much higher as compared to the pressure

die-casting method.

Flexibility of time: Changes to the geometry and also prototypes

can be implemented much quicker and in a more cost-effective way as

compared to the die-casting method.

The surface topology of the cylinder barrels, threads, very thin oil ducts and areas with very small dimensional tolerances cannot be achieved in a single production step in casting. Mechanical processing is used for this, but near-net-shape casting is a crucial requirement for the casting type so that the processing costs can be kept to a minimum. Standardized casting tolerances, which also depend on the casting method, form the basis.Requirement for the mold, the core, the material, and the casting type

Product name | Alloy steel Automobile casting part |

| Working Process | Lost wax precision investment Casting |

| Material | 42CrMo Alloy steel/aluminum |

| Production Process | Melting, Die-Casting, Trimming, Deburring, Shot Blasting, CNC Machining, Ultrasonic Cleaning, etc. |

| Equipments | CNC stamping or punching machine, CNC bending machine,CNC cutting machine, punching machines polish machine and welding machine |

| Applications | Automotive, LED light, Pneumatic Components, Industrial printer parts, Motorcycle parts, Communication, Household Appliance, Electric power tool, Sewing machine, etc |

| Service | Warm and quick response service provided by the professional Export Sales Team with many years'experlence. |

FAQ

Q1: Are you are the casting trade company or manufacturer?

We are a professional manufacturer with over 16years experience in investment casting, and we our main market is Europe.

Q2: Can you manufacture the part customized or just standard part?

We can customize part according to customer drawing and even with a draft drawing.

Q3: Whether you have IATF16949 certification?

Yes, we have IATF 16949 certification, and we our process is followed IATF 16949 requirement.

Q4: Do you have internal instruction casting defects inspection equipment?

Yes, we have, we have X-ray, magnetic detection equipment, dye penetration inspection and so on

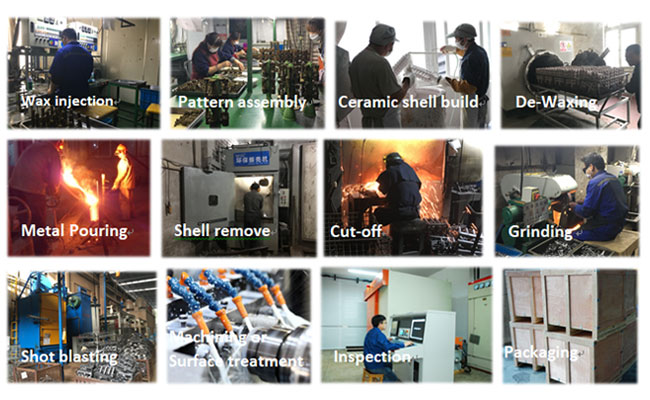

Our invertment precision casting

Process flow:

Wax Injection--Make Wax pattern and repair--Inspection--Shell Making--De-waxing--Roasting Shell and Melting Steel--Composition Inspection--Pouring--De shelling--Cutting and Grinding the pouring gate--Inspection--Heat treatment--Shotblasting--Machining--Anti-Corrosion--Final Inspection--Shipping

Precision Casting Part Packing

Our Company

Competitive Advantage:

1 . All of our products are strictly inspected and tested before packing in factory..

2 .Close to Ningbo Port and Shanghai Port.

3 . Good team for quality and delivery time control.

4 . We have a team of professional engineers to supply related technology help if customers need our tech-assistant.

5. Full APQP process to control the quality

6: Good Projects and PPAP documents experience

Our Precision Casting Manufacturing Process

|