| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Float Glass Production Line |

|---|---|

| Brand Name: | JEFFER |

| Model Number: | Customization |

| Certification: | ISO9001, ISO14001, ISO45001 |

| Place of Origin: | China |

| MOQ: | Customization |

| Price: | Negotiable |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 2 sets per annually |

| Delivery Time: | 180 days after receiving the down payment |

| Packaging Details: | Suitable packing for multi-transportation |

| Name of Product: | Float Glass |

| Capacity: | 300tpd |

| Thickness: | 4-12mm |

| Color: | Flint |

| Material: | Refractory materials, MS |

| Application: | Construction |

| Voltage: | 380V |

| Condition: | New |

| Waranty: | One Year |

| Service: | Engineers available to service overseas |

| Company Info. |

| JEFFER Engineering and Technology Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Building Construction Glass Float Glass Production Line Clear Glass Plate

1. Brief Description

The name of float glass is because of the glass liquid floating and forming on a metallic tin liquid surface. By using this forming method, it is not need to overcome the gravity of the glass, it can enlarge the width of the glass, improve the speed of stretch, and increase the capacity and scale of production.

Glass melting is the most important process in glass production, it is a forming process where the batched materials form a qualified liquid evenly with no bubbles under high temperature heating.

2. Characteristic

Because the glass liquid forms on the metallic tin liquid surface, it could achieve a high grade double faced fired polishing glass surface. The parallelism and flatness of float glass are as better as mechanical polishing effect, but it has a better mechanical capacity and chemical stability than mechanical polishing glass.

3. Scope of Supply

| Item | Description |

| 1 | Melting furnace |

| 2 | Tin batch |

| 3 | Annealing lehr |

| 4 | Cold-end equipment |

| 5 | Cullet return system |

| 6 | Shielding gas mixing station |

4. Raw Materials

Main materials are mainly including:

| Silica Sand |

| Dolomite |

| Limestone |

| Feldspar |

| Soda Ash |

| Salt Cake |

| Cullet |

Auxiliary materials as the important raw materials, it mainly includes:

| Clarify Agent |

| Coloring Agent |

| Decolorizing Agent |

| Oxidizing Agent |

| Reducing Agent |

| Combustion Agent |

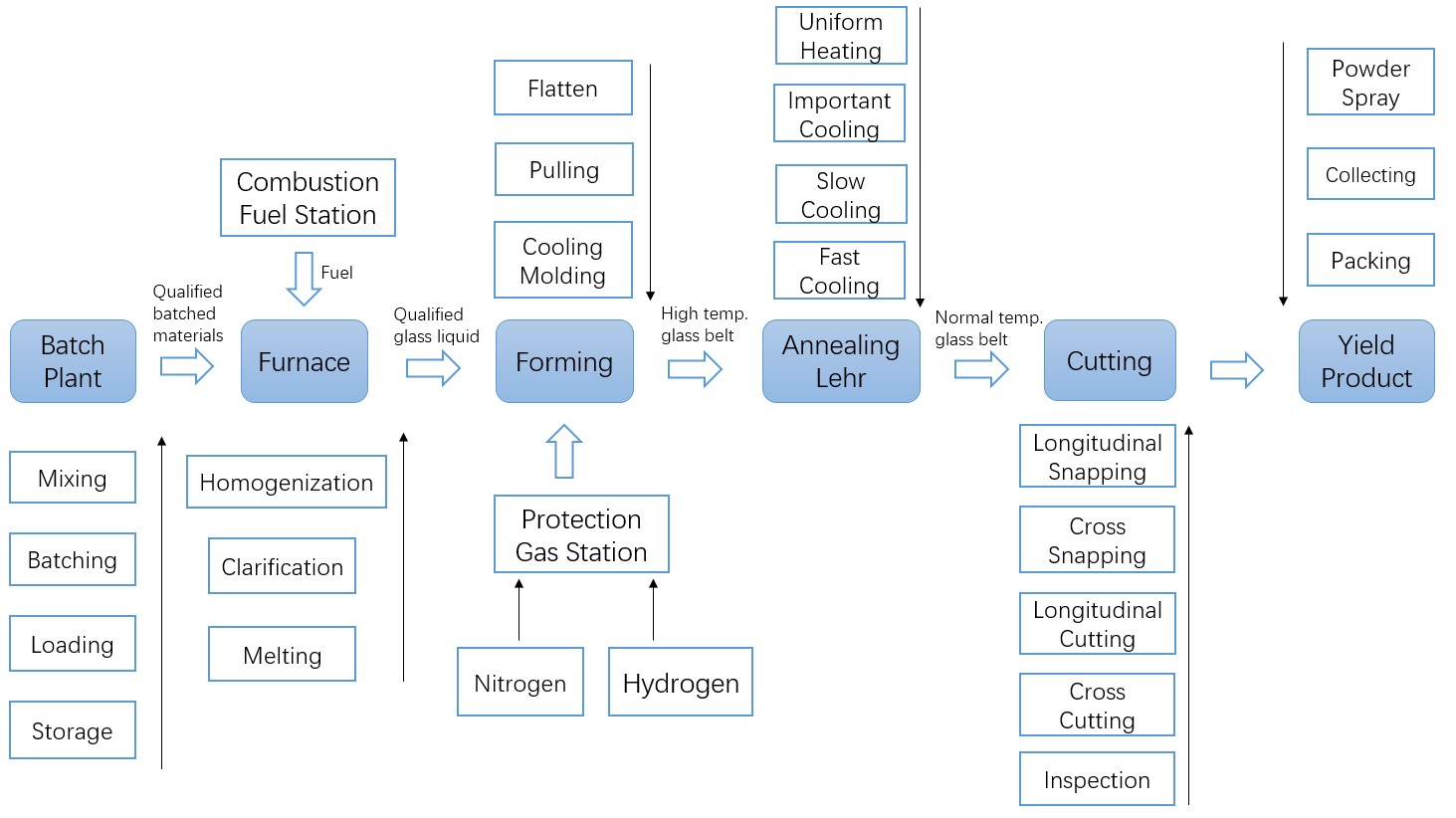

5. Technical Flow Chart of Float Glass Line

6. Main Equipment Description

6.1 Batch Plant

For batching and mixing the raw materials.

6.2 Furance

The melting tank is key part of glass production line, the refractory materials quality is very important.

6.3 Tin Bath

Glass liquid float on the metallic tin, through stretching,

forming, polishing and cooling processing, a qualified glass plate

is formed and its temperature reduces around 600°C, the transition

roller will send the plate to annealing lehr.

6.4.Protection Gas Station

The protection gas station shall operate continuously to produce and supply the required gas for tin bath.

Tin is easy to reaction with oxygen, sulfur under high temperature and form an oxide, its oxide (SnO2, SnO) will seriously pollute the glass liquid, this will affect the quality of the glass.

In the upper space of tin bath, it must be full filled with a protection gas.

Normally, Nitrogen gas (N2) and Hydrogen gas (H2) gas are to be

used as protection gas. Which is mainly for preventing or reducing

the oxidation of metallic tin liquid.

6.5. Annealing Lehr

In glass technology, annealing means to put the glass into the

annealing lehr for a certain time or reduce the temperature with a

slow speed, so as to no additional permanent stress or temporary

stress will produce. Namely, annealing also means a process which

will reduce or eliminate the thermal stress of glass.

6.6. Colde-end

7. FAQ

Q: Who we are?

A: JEFFER Engineering and Technology Co., Ltd is a professional engineering company specialising in project design, engineering technology consulting, engineering, procurement, construction (EPC), and project operation management.

Q:Can you offer design service?

A: Yes, we could design full solution drawings as per your requirements.

Q: How can I get the price

A: For product line, please provide the detailed specfication of the production you want to product, then we will privode an economic plan for your reference. For engineering service, please provide your requirement, we will provide the detailed schedule and plan for your reference.

Q: Which shipment is available?

A: By sea, by air, by rail or as your requirement.

|