| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Laying Up Machine |

|---|---|

| Brand Name: | Beyde |

| Model Number: | 1250/1+3 |

| Place of Origin: | China |

| MOQ: | 1 set |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 200 set/year |

| Delivery Time: | 90 days |

| Packaging Details: | container |

| Usage: | Cabling |

| Color: | Customized |

| Name: | laying up machine |

| Function: | laying up cores into cable |

| Plc: | SIEMENS |

| Stranding pitch (mm): | 180-3166 |

| Warranty: | 12 Months |

| Inverter: | Japan YASKAWA |

| Payment: | 30% T/T |

| RPM: | 50r/min |

| Support: | bigh bearing support |

| Company Info. |

| Beyde Trading Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

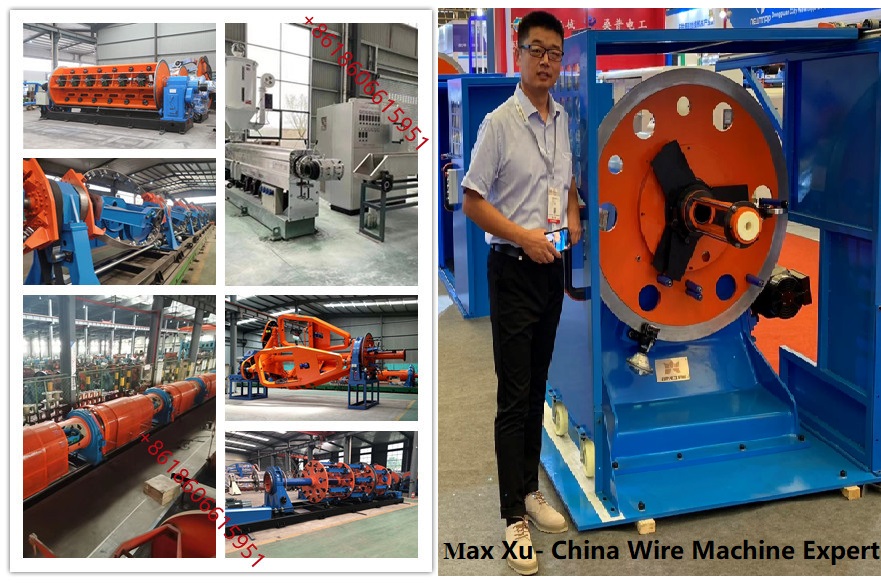

High Speed Cradle Laying-up Machines For 35-240SQMM ABC Cable Making Equipment

1. Application:

This machine is mainly used for round or fan-shaped stranding of power cables with 4 cores and less.

2.Equipment characteristics

The programmable controller and touch screen of the machine control the start, operation and synchronous rotation of the motors of all parts of the machine. The pitch is set on the man-machine interface, which is accurate, fast and convenient.

Φ 1250 type three disc winch cage adopts double support structure of front and rear large bearings instead of traditional supporting wheel structure, which is more suitable for high-speed rotation and improves production efficiency.

3. Techincal parameter

| 2.1 | Single wire diameter | φ10-φ30mm |

| 2.2 | Max strand diameter | φ80mm |

| 2.3 | Strand pitch range | 1000-3600mm |

| 2.4 | Cage max rotation speed | 50r/min |

| 2.5 | capstan line speed range | 77.7m/min |

| 2.6 | Taping head max rotation speed | 650r/min |

| 2.7 | Taping head pitch | 16-269mm(stepless adjustable) |

| 2.8 | capstan wheel diameter | φ2000mm |

| 2.9 | Take-up bobbin size | PN1250-2500 |

| 2.10 | Center Pay-off bobbin size | PN1250 |

| 2.11 | Main motor power | 45KW(AC variable frequency motor) |

| 2.12 | Taping motor power | 11KW(AC variable frequency motor) |

| 2.13 | Capstan motor power | 15KW(AC variable frequency motor) |

| 2.14 | Machine center high | 1000mm |

3. Main componet

| 3.1 | 1250/1+3 stranding cage | 1 set |

| 3.2 | Double row die holder | 1 set |

| 3.3 | φ600x2 double taping machine | 1 set |

| 3.4 | Mechanical electronic meter counter | 1 set |

| 3.5 | φ2000 capstan device | 1 set |

| 3.6 | φ 2500 take-up and traverse frame | 1 set |

| 3.7 | Electrical control system | 1 set |

| 3.8 | Safety fence | 1 set |

4.2.6 The 1 + 3 winding cage consists of two 1250 separate wire reel racks and Φ 1250 three disc winch cage.

4.2.7 Φ 1250 single reel frame is a cradle type front and rear double support structure, and the wire core on the reel is threaded through the main shaft of the winch. Through the manual clutch, it can be connected with Φ 1250 three disc stranding body rotates synchronously and can also be fixed to realize untwisting and twisting circular line, untwisting and twisting sector line and parking operation.

4.2.8 Φ 1250 three disc winch adopts double support of front and rear bearing seats, and the wire reel frame is evenly distributed on the same circumference with conical structure. The inlet and outlet ends are supported by self-aligning roller bearings. The main shaft is made of high-quality seamless steel pipe, and the large and small pressure bearing discs are connected with the main shaft by the combination of flat key and expansion sleeve. Large pressure bearing plates are welded and annealed. It is driven by a separate AC variable frequency motor with a slow positioning driving device, variable frequency control and left-right rotation function. Planetary gear train mechanism realizes untwisting and twisting circular line, non untwisting and twisting sector line, and parking operation.

4.2.9 All wire reel racks are welded parts, which adopt end shaft type manual clamping and loosening wire reel, with mechanical locking protection function. Electric pre torque, non-stop operation.

4.2.10 The setting out tension is controlled by mechanical friction, and the tension is manually adjusted.

4.2.11 Pneumatic brake.

4.2.12 Φ The outgoing end of 1250 three reel winch is equipped with 12 filling rope paying off frames

|