| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Custom Injection Mold |

|---|---|

| Brand Name: | LiQi |

| Model Number: | OEM |

| Certification: | ISO,GE |

| Place of Origin: | China |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 100000 Piece/Pieces per Month |

| Delivery Time: | 35-50 days |

| Packaging Details: | Wooden case |

| Mould core material: | P20/ H718 /S136 |

| Gate Type: | Side gate |

| Design: | Chair Design |

| Cavity: | Multi |

| Runner System: | Hot runner/ Cold runner |

| Mold Life: | 250000-500000shots |

| Company Info. |

| JinJiang LiQi Mould Co., Ltd |

| View Contact Details |

| Product List |

Both Hot Or Cold Runner Custom Injection Mold Household Mould

| Product Description | Both Hot Or Cold Runner Custom Injection Mold Household Mould |

| Plastic Materials: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,...etc. |

| Standard: | ISO9001:2008 |

| Other materials: | Rubber, Slilconce rubber, LSR,Aluminum, Zinc,Copper...Metal...etc. |

| Quality: | RoSH and SGS standard |

| Feature: | Non marking and Non flash |

| Size: | According to your 2D, 3D Drawing |

| Color,Quantity,Unit price,Tooling cost,Tooling size: | To be discussed |

| Package: | Standard exported Wooden box packed, Fumigation process(upon required) |

| Mold Building Lead Time: | T1, 4-5 weeks, Part measurement report (upon required). |

| Export Country: | Europe, Japan, America, Australian, UK, Canada, France, Germany, Italy...etc.: |

| Experience: | 13 years experience in plastic injection mold making and plastic prouducts produce. |

| To be discussed | In-Mold Decoration, Injection Mould, Plastic Mold, Overmould, 2K Mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold,Collapsible Core Mold, Die Sets, Compression Mold, Cold Runner System LSR Mold,...etc. |

| Mould Base: | Hasco Standard, European Standard, World Standard |

| Mould Base Material: | LKM, FUTA, HASCO, DME,...etc. Or as per Customer's Requirment. |

| Surface Finish: | Texture(MT standard), High gloss polishing |

| Cavity/Core Steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 ...etc. |

| Hot/ Cold Runner | HUSKY, INCOE, YDDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand...etc. |

| Mould Life: | 5,000 to 1,000,000 Shots. (According to your working environment.) |

| Design & Program Softwares: | CAD, CAM, CAE, Pro-E, UG, Soild works, Moldflow, CATIA....etc. |

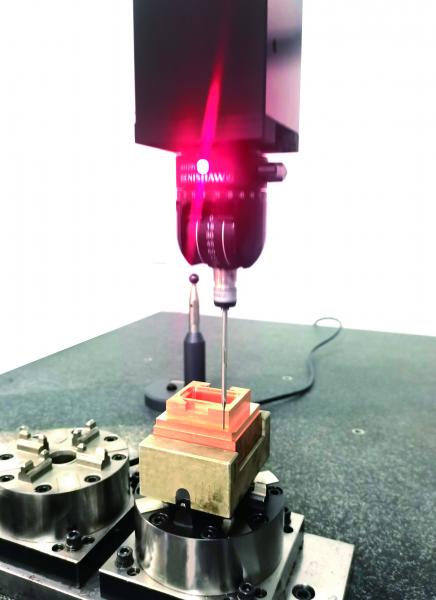

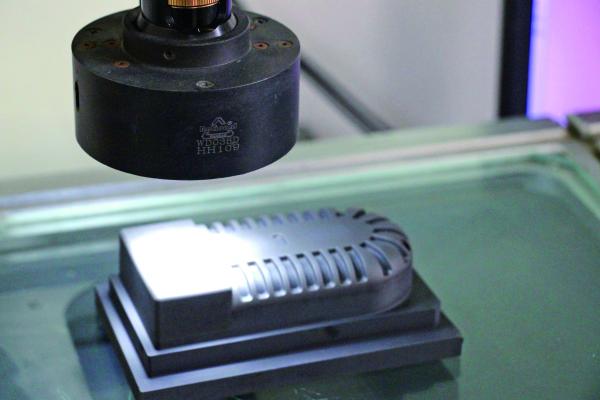

| Equipments: | High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-3000T available. |

Product Description:

| Product Material | PP/PVC/PE/HDPE/TPU/PMMA/TPU/NYLON6/NYLON66 |

| Mould material | P20/H718/S136 |

| Mould life | 500,000 shots |

| Software | CAD/IGS /STEP/STP /PDF |

| Package | Wooden case |

| Gate type | Pinpoint Gate, Edge Gate, Sub Gate, Film Gate, Valve Gate, Open Gate, etc. |

| Mould time | 40 days for first time testing sample |

| Injection time | 3-5 days after confirmation of the sample |

| Shipping time | 18-30 days sea shipment |

| Payment terms | 50% advanced payment before mould making, balance after sample confirmed. |

Introduction:

Some injection molders claim to provide custom services, but the industry lacks a clear definition of what “custom” really means — resulting in some manufacturers contracting with molders that are woefully unqualified to accurately produce highly specialized designs. Just because a molder can facilitate development of an original tool doesn’t constitute a truly custom service (or ensure a desirable outcome). Many of these molders are limited to producing simplistic designs and lack the ability to engineer complex plastic parts with precise specifications and tight tolerances.

Custom Injection Mold tools:

Custom Injection Mold are typically made of steel and only pay for themselves when you order larger quantities. As an alternative, we offer 3D-printed injection molding tools that save you up to 80 percent, even on small quantities of 1 to 500 components.

It’s vital to evaluate how an injection molder will align with your project needs. A part used in a medical or military application as compared with a toy or food container, for example, demands the attention and expertise of injection molders that are truly experienced in specialized complex design, engineering and support. Plastic components used in such applications must adhere to strict specifications and compliance requirements.

Equipments:

High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-3000T available.

|