Why Choose us for Color Coated Aluminum Sheet Polyester Coated

Aluminum Sheet?

1.We are The Professional Manufacturer For Coated Aluminum Coil and

Sheet .

Choose us , you can save a lot us time from the trader business, We

get your offer and produce the order as your request directly. and

we are the professional in this industry , it is easy to understand

what you want to get, Let us know what products you are produce for

,then we can according to your requirements recommend the material

for you.

2. We Dipped In The Coated Aluminum Industry More Than 30 Years.

From 1992, We started from a school subsidiary house for printing

the paper. Then we went up year by year. We went through the Asian financial crisis in 1997, the global financial crisis in 2008,then became more and more stronger,

in order to save energy for our company, Our market from developed

countries such as U.S., U.K. to South-east countries, then back to

Europe and Domestic market. We have owned more and more clients

feedback due to the well reputation from the crisis.

3.We Export The Coated Aluminum Products More than 100 Countries

worldwide.

It is the most important that we are well known the requirement

from different countries with different standards. From American

stand to Europe Standard, We can easy to identify and strictly

according to it. Also we are well know the different rule from

different countries such as American clients well need the

thickness in plus tolarance,but it should be minus tolarance

thickness in south-east asia and Africa area.

4.We Never use the Re-Cycle Alumiunm Material.

All of us know that aluminm are the re-cycle alloy that can save

energy for our earth. but most of the color coated aluminum

products are used in very strict and inclement weather district.

The re-cycle aluminum can not staisfy the requirement of it .

That's why we can continue our business for more than 30 years here

and this is the reason why more and more clients choose us with our

coated aluminum products.

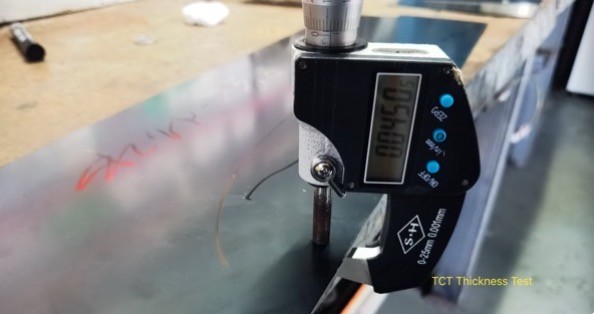

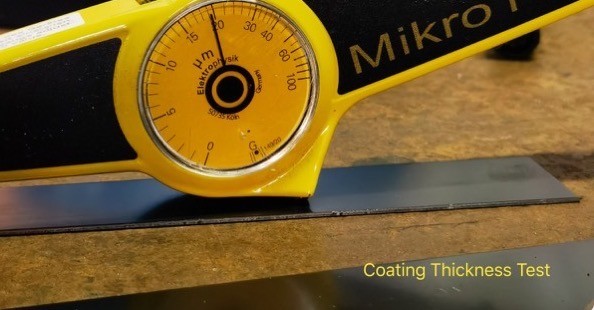

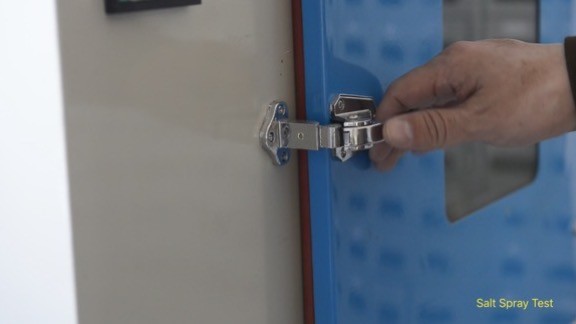

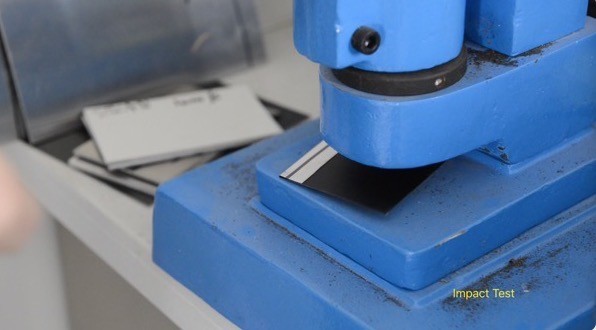

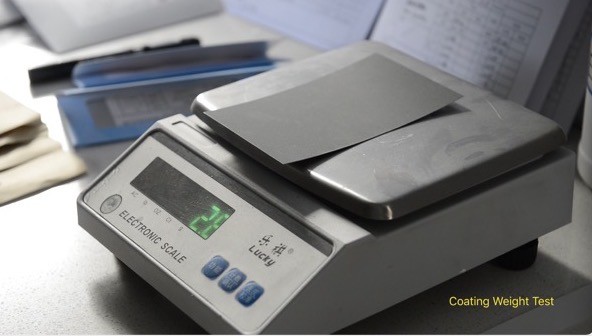

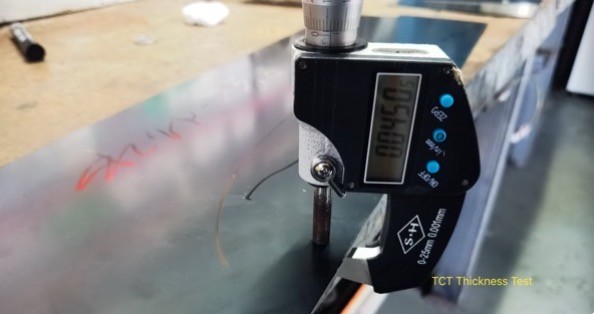

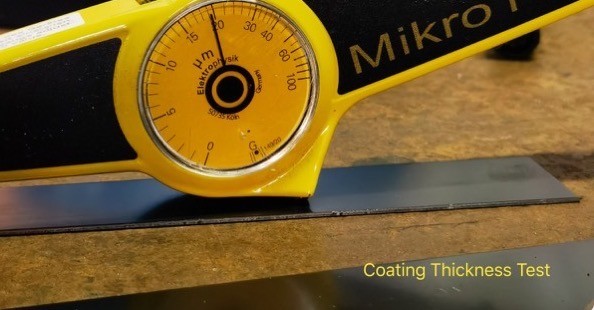

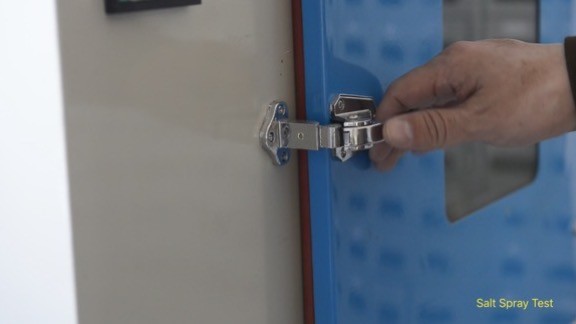

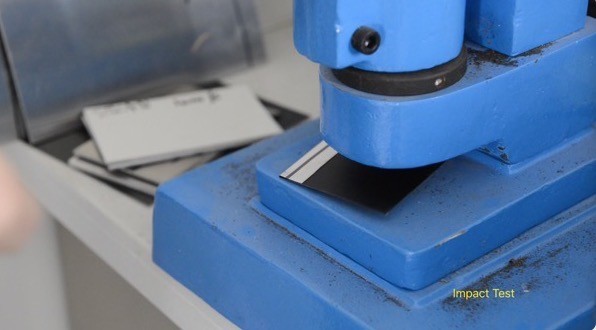

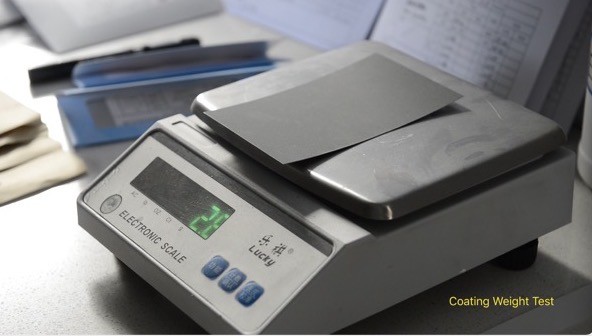

5.Full Quality Test Room We Have In Our Company Before the Order

Loading Out.

Here in our company we have a full set of machines that can test

any items of the coated aluminum quality such as coating thickness,

Analysis of the Coating Content, The Aluminum Alloy Components,

Temper, Tensile, Hardness,Etc., All the material that ship out to

any countries should be test all the items during the production.

6.Worldwide serve systems.

We have the 24 hours business service and we can solve any problem

from North America to South Africa in one-day-time.

Specification

| Pre-painted Color Coated Aluminum Coil |

| Product | Pre-painted Color Coated Aluminum Coils |

| Thickness | 1.0mm |

| Diameter | 1500mm |

| Material | AA3105 |

| Temper | H24 |

| Inner Diameter | 500 |

| Color | Matt Black Color |

| Coating thickness | PE coating |

| PE Paint Coating : Not Less Than 28um |

| Packing | Export Standard Wooden Pallets |

| Payment Terms | L/C at sight or 30% T/T in advance as deposit |

| MOQ | 8Tons Per Specification |

| Delivery Time | Within 45 Days |

| Loading Port | Shanghai Port |

| Application | Roofing,Gutter,Siding, Joint. Wall,Truck,Container |

Application of AA3105 H24 Matt Surface Black Polyester Paint Coated Aluminum Coil

Architectural Cladding

Interior Decorations

Doors and Door Frames

Furniture Manufacturing

Window Shutters

Signage and Displays

Exterior Trim and Molding

Ceiling Systems

Garage Doors

Roofing Applications

Exhibition Stands

Transportation Industry

The difference between 3003 aluminum Alloy and 3105 aluminum Alloy

Both 3003 and 3105 are aluminum alloys, but they have some

differences in terms of their chemical composition and properties.

Here's a comparison between the two:

3003 Aluminum Alloy:

Chemical Composition:

3003 aluminum alloy is primarily composed of aluminum (about

98.6%), manganese (1-1.5%), and trace amounts of other elements.

Properties:

Good corrosion resistance, making it suitable for various

applications.

Moderate strength, not as strong as some other aluminum alloys.

Excellent formability and weldability.

Commonly used for general-purpose applications, such as cooking

utensils, kitchen equipment, and heat exchangers.

Applications:

Roofing materials, cooking utensils, kitchen equipment, heat

exchangers, and other general-purpose applications where corrosion

resistance and formability are important.

3005 Aluminum Alloy:

Chemical Composition:

3005 aluminum alloy is primarily composed of aluminum (about

98.6%), manganese (1-1.5%), and a small amount of magnesium

(0.6-1.1%).

Properties:

Improved corrosion resistance compared to 3003, especially in more

aggressive environments.

Good formability and weldability.

Moderate strength.

Often used in applications where increased corrosion resistance is

required compared to 3003.

Applications:

Similar to 3003, 3105 is used in general-purpose applications.

However, it is preferred in situations where enhanced corrosion

resistance is necessary, such as in marine environments.

Key Differences:

Corrosion Resistance:

3105 generally offers better corrosion resistance compared to 3003,

especially in more challenging environments. This is due in part to

the inclusion of magnesium in the alloy.

Strength:

The strength properties of 3003 and 3105 are relatively similar.

Neither is known for high strength, but they are suitable for

applications where strength is not a critical factor.

Applications Focus:

Both alloys find application in general-purpose uses. However, 3005

is often preferred when increased corrosion resistance is a

priority.

Magnesium Content:

3105 contains a small amount of magnesium, contributing to its

enhanced corrosion resistance. In contrast, 3003 does not contain

magnesium.

Common Uses:

Both alloys are commonly used in the manufacture of heat

exchangers, cooking utensils, kitchen equipment, and other

applications where corrosion resistance and formability are

important.

In summary, while 3003 and 3105 aluminum alloys share similarities

in composition and application, the inclusion of magnesium in 3105

provides improved corrosion resistance, making it suitable for

applications where exposure to more aggressive environments is a

concern. The choice between the two would depend on specific

project requirements and the level of corrosion resistance needed.

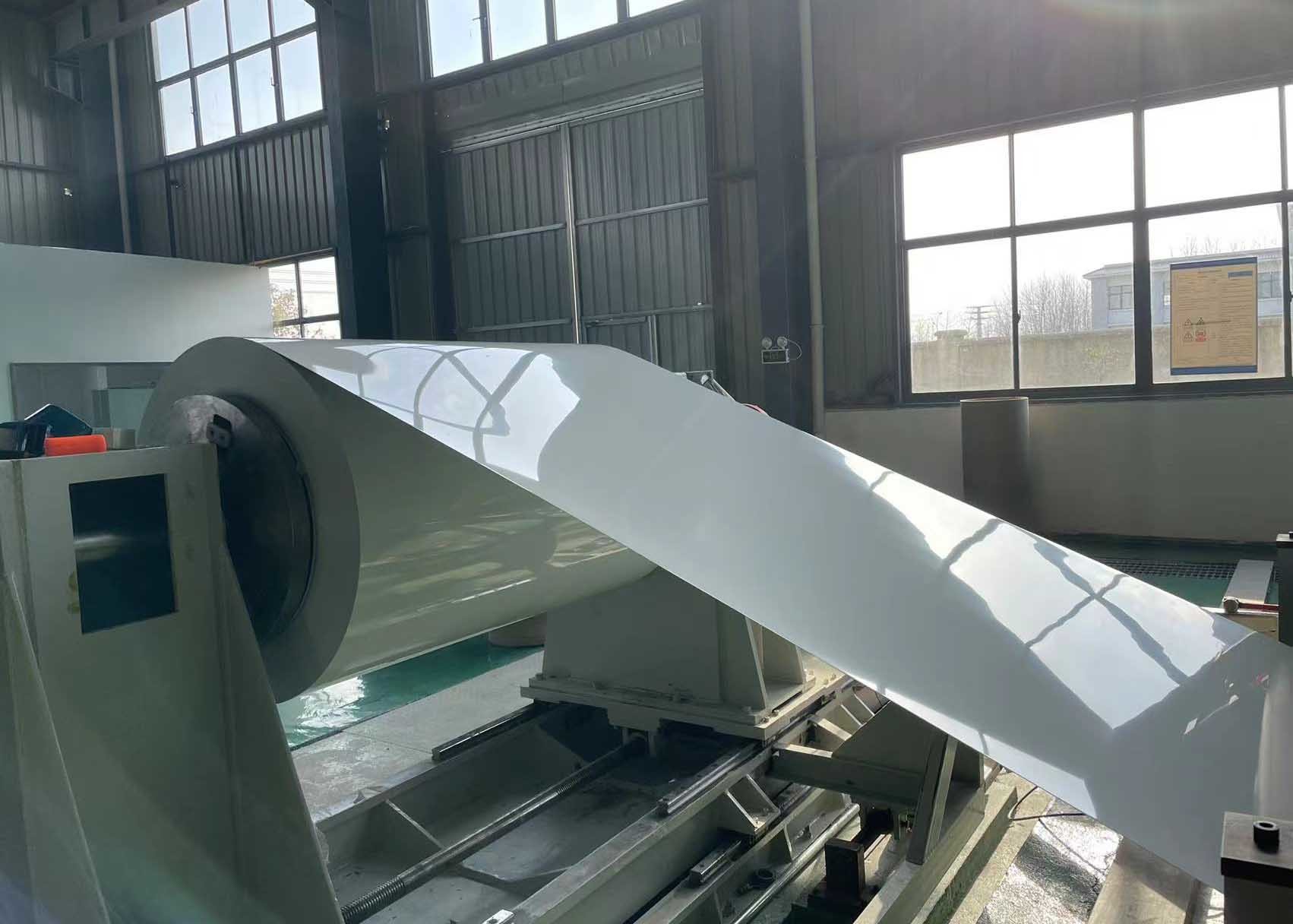

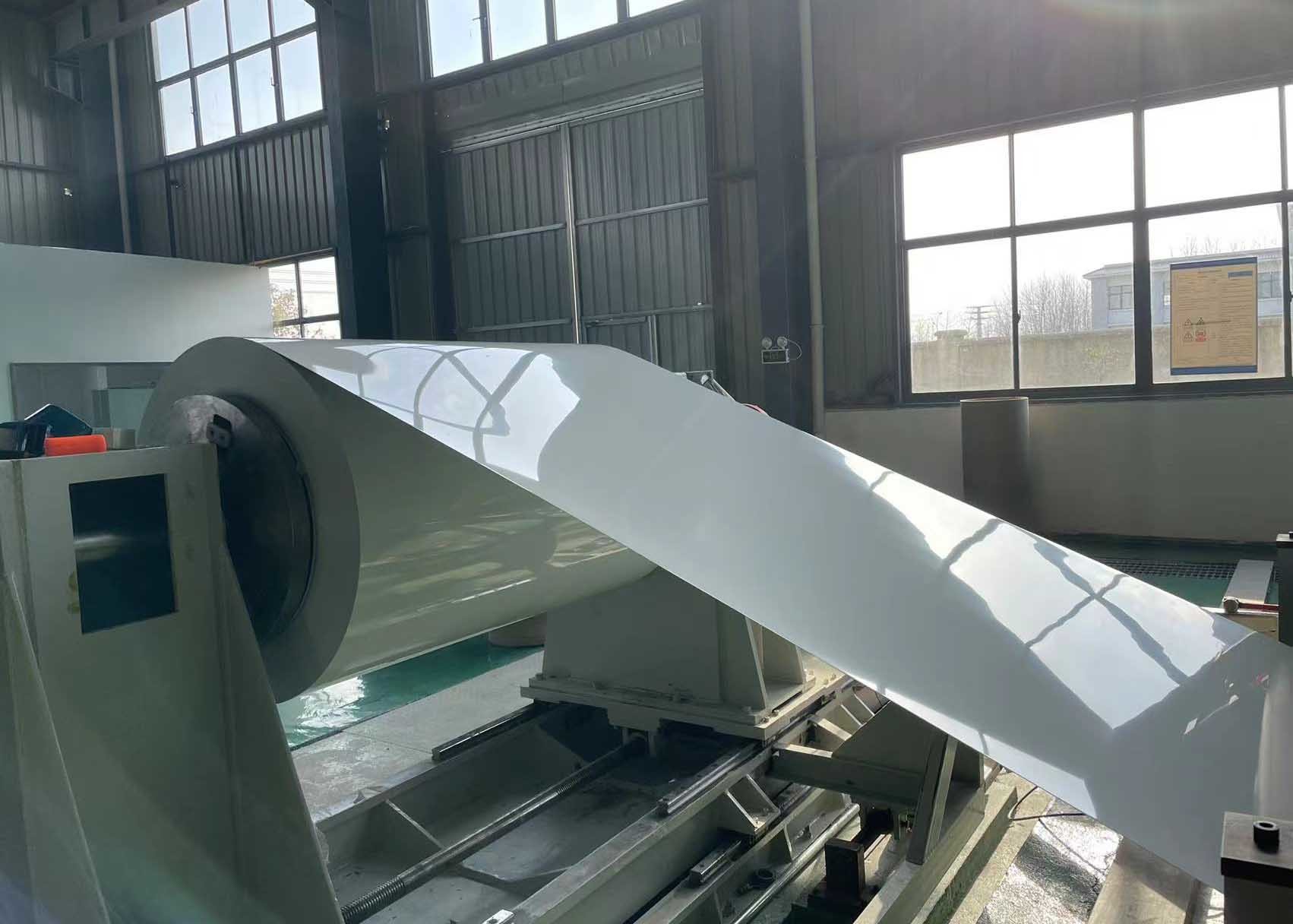

Production Line Photos:

Test Items