| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Apron Feeder |

|---|---|

| Brand Name: | Green Eco-Equipment |

| Certification: | ISO9001:2008/CE |

| Place of Origin: | Henan, China |

| MOQ: | 1 |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 10 sets per month |

| Delivery Time: | 10~15 work days after receiving fullpayment. |

| Packaging Details: | In Bulk/Tray/Wooden Case/As Customer's Requirement |

| Material: | Cast Steel |

| Voltage: | 220V/380V/As Customer's Request |

| Material Feature: | Heat Resistant |

| Capacity(t/h): | 30-900t/h |

| Dimension(L*W*H): | As Customer's Request |

| Granule Size: | <1000mm |

| Suitable Material: | Cement, Coal, Gravel, Stone |

| Application: | Construction works, Mining, Power Plant, Metallurgical Industry |

| Warranty: | 2 Years |

| After-sales Service Provided: | Field installation, commissioning and training |

| Name: | Steel Pan Conveyor |

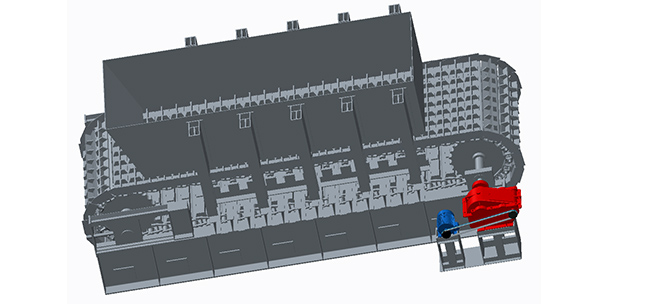

Heavy Stone Apron Plate Type Feeder No Leak Aprons Steel Pan

Conveyors

Product Description

Heavy duty apron feeder /plate feeder is widely used in metallurgy,

coal, cement, building materials, electric power, chemical

industry, casting and other industries, especially suitable for

conveying some solid materials with high temperature, large size,

sharp edges and strong grinding ability.

Features

1, The width of the material particle size not more than the apron feeder 0.6 times;

2, The material temperature on the apron feeder /plate feeder is

not more than 450 ℃;

3, The apron feeder layout form: various, horizontal and inclined

layout; The inclination angle is not more than 25 degrees;

4, Apron feeder conveying length: generally 5-10m, the longest is

less than 20m;

5, Apron feeder /plate feeder Traction chain: pitch plate pin

roller chain, heat treatment, good wear resistance, high tensile

strength, long service life;

6, Apron feeder chain plate: the stamping tank body is adopted to

make the material connection more stable, and the tank bottom plate

is overlapped by circular arc to reduce material leakage;

7, Apron feeder drive: the motor can adopt speed regulating motor,

which can be adjusted manually. The speed is 0.3 ~ 0.5m/min, which

is widely used and runs stably, so as to select the conveying

capacity more reasonably;

8, Closed form: the default is open conveying material, the dust is

large, if there are environmental protection requirements, can be

made into a fully closed plate feeder.

Main Parameters

| Model | Plate width | Head to tail shaft center distance | Speed | Feed size | Capacity | Power | Reference weight |

| (mm) | (mm) | (m/s) | (mm) | (t/h) | (kw) | (kg) | |

| WBZ160-9 | 1600 | 9000 | 0.01-0.15 | ≤1000 | 900 | 30 | 50000 |

| WBZ180-8 | 1800 | 8000 | 0.01-0.15 | ≤1000 | ≤1000 | 37 | 59000 |

| WBZ200-10 | 2000 | 10000 | 0.01-0.15 | ≤1000 | ≤1100 | 37 | 82000 |

| WBZ220-10 | 2200 | 10000 | 0.01-0.15 | ≤1200 | ≤1200 | 45 | 85000 |

| WBZ230-10 | 2300 | 10000 | 0.01-0.15 | ≤1200 | ≤1300 | 45 | 86000 |

| WBZ240-10 | 2400 | 10000 | 0.01-0.15 | ≤1600 | ≤1400 | 2x37 | 95000 |

| WBZ250-11.5 | 2500 | 11500 | 0.01-0.15 | ≤1800 | 1500 | 2x45 | 105000 |

Detailed photos of steel pan conveyor

Scope of application

The apron feeder are: Light duty apron feeder, middle duty apron

feeder and heavy duty apron feeder.

The apron feeder can be used for continuous and uniform feeding

from storage bin to crusher, conveyor or other machinery. It can

also be used for short distance conveying of materials with larger

block size and density. It can complete heavy work in harsh

environment, and has great adaptability to the change of particle

size composition of materials, temperature, viscosity, frost, rain

and snow or frozen materials.

|