| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Sheet Metal Stampings |

|---|---|

| Brand Name: | DX |

| Certification: | IATF16949 |

| Place of Origin: | China |

| MOQ: | 1000pcs |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Supply Ability: | 30000pcs per month |

| Delivery Time: | 25days |

| Packaging Details: | Bag,box/carton, pallet /crate |

| Product: | Tin plated craft gift sheet metal stamping part |

| Material: | Mostly use stainless steel , such as SS301, SS304, SS316, etc |

| Surface: | Mechanical mirror polishing,chemical solution mirror polishing |

| Mould type: | Progressive stamping mould |

| Certificate: | SGS, ISO9001, IATF16949 |

| File formats: | Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. |

| Service: | Customized OEM ODM |

| Application: | Furniture hardware, electronic hardware, construction machinery parts, metal processing machinery parts, Surgical instruments, Automotive parts, Optical products, LED flash lights etc. |

| Company Info. |

| Jiaxing Dexun Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

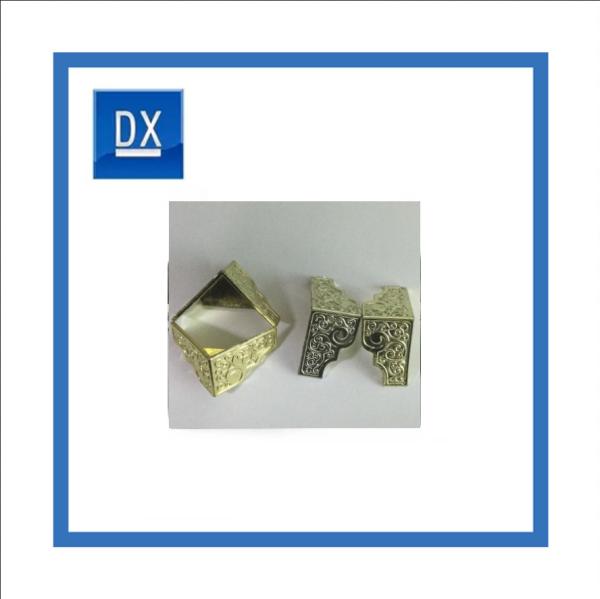

Tin plated craft gift sheet metal stamping part

Tin plating and its alloy is a kind of coating with good solderability and certain corrosion resistance, widely used in electronic components and printed circuit boards. In addition to physical methods such as hot dip and spraying, electroplating, dip plating and chemical plating have been widely used in industry because of their simplicity.

| Description | Tin plated craft gift sheet metal stamping part |

| Material | Mostly use stainless steel , such as SS301, SS304, SS316, etc |

| Surface | Mechanical mirror polishing ,chemical solution mirror polishing |

| QC | 100% inspection before shipment |

| Testing | CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge;Dial gauge;Marble platform |

| Tolerance | +/-0.05 mm |

| Service type | OEM/ODM |

| Application | Construction machinery parts, metal processing machinery parts, Surgical instruments, Automotive parts, Optical products, LED flash lights etc. |

Advantages of Acid bright tin plating:

1. Tin is reduced by bivalent, saving electricity consumption;

2. Plating bath has high conductivity, low bath current and high current efficiency;

3. The operating temperature is close to room temperature, without heating equipment;

4. Gloss coating can be obtained by using appropriate additives;

5. Less damaging to the substrate.

Disadvantages:

1. Operation and bath management need to be very careful to get a good coating.

2. Additives are needed, otherwise it is easy to produce branches or nodular coatings.

3. Insoluble anodes cannot be used.

4. Corrosive, plating tank must be rubber lining.

5. Tin divalent may oxidize to tin tetravalent and become blunt.

|