| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Steel Rail Wheels |

|---|---|

| Brand Name: | kingrail |

| Model Number: | 250mm |

| Certification: | ISO |

| Place of Origin: | China |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 1 million pcs/year |

| Delivery Time: | 1-30 working days |

| Packaging Details: | standard export package, or as per customer request |

| Diameter: | 0-1450mm |

| Production: | Casting and forging as per customer request |

| Material: | 4140,42CrMo,60E, etc |

| Inspection: | 100% inspection, UT,MT, sizes, mechanical property |

| Progress: | Forging-machining-inspection-heat treatment-machining-inspection |

| Hardness: | 150-560HB |

| Application:: | Railway, rail cart or shipyard,Rail road vehicles, railcar |

| Max. capacity: | Up to 500ton |

| Export area: | Germany, French, UK, US, South Korea, South Africa, etc |

| Sizes: | as per customer drawing |

| Company Info. |

| Maanshan Kingrail Technology Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

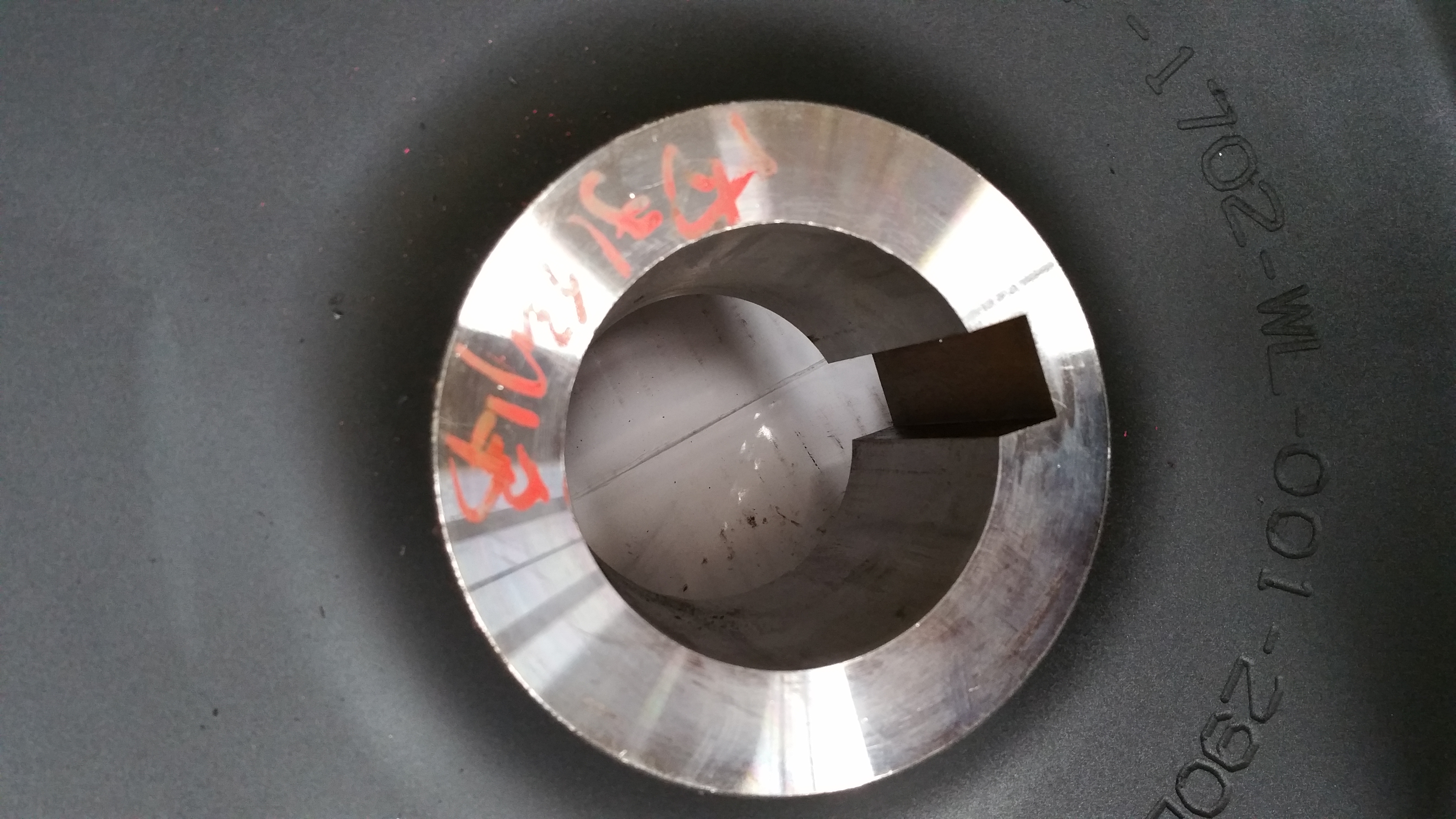

Detailed specification of crane wheels forged production 42CrMo as material 380mm diameter with bolt hole

Processing form: processing according to drawings, customized by

customers.

Processing capacity: within 30 tons, within 5 meters of large outer

diameter.

Process types: free forging, model forging, tire die forging and

special forging.

Application areas: large machinery and equipment, lifting

equipment, metallurgy, chemical industry, engineering, marine

industry and other fields.

Common materials of crane wheels forged production 42CrMo as

material 380mm diameter with bolt hole

Carbon Steel: A350LF2, A105, Q235, Q355D, A694F52, A516-GR65,

EN10222, P280GH, P245GH, P250GH, JIS S25C, SS400, S20C, 16Mn,

C22.8, Q345B/C/D, 1055, 1045, C50, C45, 10#, 20#, 35#, 45#, 40#,

50#, 60# and other forgings.

Stainless Steel: ASTM, A182, F304/304L, F316/316L, F316H, F310,

F321, JB4728-2000, OCR18Ni10Ti, JB4728-2000, OCR17NI12Mo2, 2205,

2507, 2103, 904L, 254SMD3, 304LN3, 316LN 3cr13, 4cr13, 321, 302,

W1813N, W2014N, W2018N, W2020N, P550, Cr18Mn18N and other

forgings.

Alloy Steel: 42CrMo, A182F1, F5, F9, F11, F91, F92, F22, 12Cr2Mo1,

10Cr9Mo1VNbN (F91), 10Cr9MoW2VNbBN (F92), JB4726-2000, 15CrMo,

JB4726-2000, 12CrMoV, 35Cr30, 4140, 4340 a -8Mo, 15-5PH, AerMet100

and other forgings.

Special steel: ASTM182F51, S31803, A182F309, Monel N04400, A182F310 and other forgings.

Tool and die steel: P20718, NAK80, S50C, 4Cr13, 3Cr17Mo, 5CrNiMo, 5CrMnMo, 4Cr2NiMoV, S7, H10, H11, H12, H13, H13 MOD, SUP H13,

D2, A2, A6, A8, O1, O2, 9Cr2Mo, MC3, MC5, 7Cr3, 21CrMo10, 1Cr17Ni2, 310 and other forgings

Heat-resistant steel: 12CrlMoVG, P11, P22, P91, P92, F92, InconeI740H, CCA617, Sanicro25 alloy and other forgings

Bearing steel: G20CrNiMoA, G2CrNi2MoA, G20Cr2Ni4, GCr15, GCr15SiMn, GCr15SiMo, GCr18Mo, M50, M50NiL, CSS-F42L, Cronidur30 and other forgings

Gear steel: 42CrMo, 20CrNi2Mo, 34CrNi3Mo, 40CrNiMo, 20CrMnMo, 35CrMo, 18CrNiMo7-6 and other forgings

Packaging: Plastic, plywood boxes or pallets.

Advantages of crane wheels forged production 42CrMo as material 380mm diameter with bolt hole: strong heat dissipation, good forging performance, good heat dissipation of thin walls, large grounding area

The Production Railway Wheels Process

1. Wheels Steel Melting 2. Round Billet Sawing Cutting 3. Heating 4. Phosphorus 5. Stamping Forming 6. Rolling 7. Bending Punch 8. Hot Stamping 9. Laser Measurement 10. Drop Stack 11. Roughing 12.Hardening 13.Tempering 14. Sampling 15. Pre-processing 16. Finishing 16. The Cold Print 17. Static Equilibrium 18. The Cold Print 19. Hardness Testing 20. Ultrasonic Testing 21. Magnetic Particle Testing 22. Shot Peening 23. Painting Packaging

Main Testing and Inspection Device for crane wheels forged production 42CrMo as material 380mm diameter with bolt hole

| No. | Device | Type | Qty | Status | Note |

| 1 | End quenching machine | DZJ-I | 1 | working | Testing |

| 2 | Electric resistance furnace | SX2-8-12 | 2 | working | Testing |

| 3 | Inverted metallurgic microscope | 4XCE | 1 | working | Inspection |

| 4 | High temperature box resistance furnace | SX2-4-13 | 1 | working | Testing |

| 5 | Automatic digital display Rockwell hard-tester | 200HRS-180 | 1 | working | Inspection |

| 6 | Electronic Brinell hardness tester | THB-3000 | 1 | working | Inspection |

| 7 | HR-150B Rockwell hardness tester | HR-150B | 1 | working | Inspection |

| 8 | Rapid multi-element analyzer | JS-DN328 | 1 | working | Inspection |

| 9 | Electric arc furnace | JSDL-8 | 1 | working | Testing |

| 10 | Rapid multi-element analyzer(C & S) | JS-DN328 | 1 | working | Inspection |

| 11 | Infrared thermometer | AR872 | 2 | working | Inspection |

| 12 | Portable chemical composition analyzer | AR872 | 2 | working | Inspection |

| 13 | Test specimen sampler | KW30-6 | 1 | working | Inspection |

|