| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | PCB Board Manufacturing |

|---|---|

| Brand Name: | SenYan |

| Model Number: | PCB manufacturing |

| Certification: | ISO14001,ISO13485,ISO9001,IATF16949 |

| Place of Origin: | China |

| MOQ: | 1pcs |

| Price: | Negotiate |

| Payment Terms: | L/C, D/A, D/P, T/T |

| Supply Ability: | 100000pcs |

| Delivery Time: | 1-30days |

| Packaging Details: | PCB: Vacuum Packing / PCBA: ESD Packing |

| Name: | PCB manufacturing |

| Solder mask: | Green |

| Silk Screen: | White |

| Surface Technics:: | HASL-F |

| Max panel size: | 32"×20"(800mm×508mm) |

| Layer count: | 2~18 |

| Type: | Customizable |

| Item: | china direct pcb manufacturing |

SMT Manufacturing Capability | |||

Item | Manufacturing Capability in process | Manufacturing Method | |

| Production size(Min/Max) | 50×50mm / 500×500mm | ||

| Production board thickness | 0.2 ~ 4mm | ||

Printing solder paste | Support method | Magnetism fixture, vacuo platform | |

| Clamping method | Sticking up by vacuo, clamping on both sides ,flexible clamping with sheet, flexible clamping with thick board | ||

| Cleaning Method of printing solder paste | Dry method+ wetting method+ Vacuo method | ||

| Accuracy of printing | ±0.025mm | ||

| SPI | Repeated accuracy of volume | <1% at 3σ | |

Mounting component | Components size | 0603(Option) L75mm Connector | |

| Pitch | 0.15mm | ||

| Repeated accuracy | ±0.01mm | ||

AOI | FOV size | 61×45mm | |

| Test speed | 9150mm²/Sec | ||

| 3D X-ray | Shootingangle | 0-45 | |

Rigid RPCB Manufacturing Capability | ||

Item | RPCB | HDI |

minimum linewidth/linespacing | 3MIL/3MIL(0.075mm) | 2MIL/2MIL(0.05MM) |

| minimum hole diameter | 6MIL(0.15MM) | 6MIL(0.15MM) |

minimum solder resist opening (single-side) | 1.5MIL(0.0375MM) | 1.2MIL(0.03MM) |

| minimum solder resist bridge | 3MIL(0.075MM) | 2.2MIL(0.055MM) |

| maximum aspect Ratio (thickness/hole diameter) | 10:1 | 8:1 |

impedance control accuracy | +/-8% | +/-8% |

| finished thickness | 0.3-3.2MM | 0.2-3.2MM |

| maximum board size | 630MM*620MM | 620MM*544MM |

| maximum finished copper thickness | 6OZ(210UM) | 2OZ(70UM) |

| minimum board thickness | 6MIL(0.15MM) | 3MIL(0.076MM) |

| maximum layer | 14层 | 12层 |

| Surface treatment | HASL-LF,OSP ,Immersion Gold, Immersion Tin ,Immersion Ag | Immersion Gold,OSP,selectiveimmersion gold, carbon print |

| Min/max laser hole size | / | 3MIL / 9.8MIL |

| laser hole size tolerance | / | 10% |

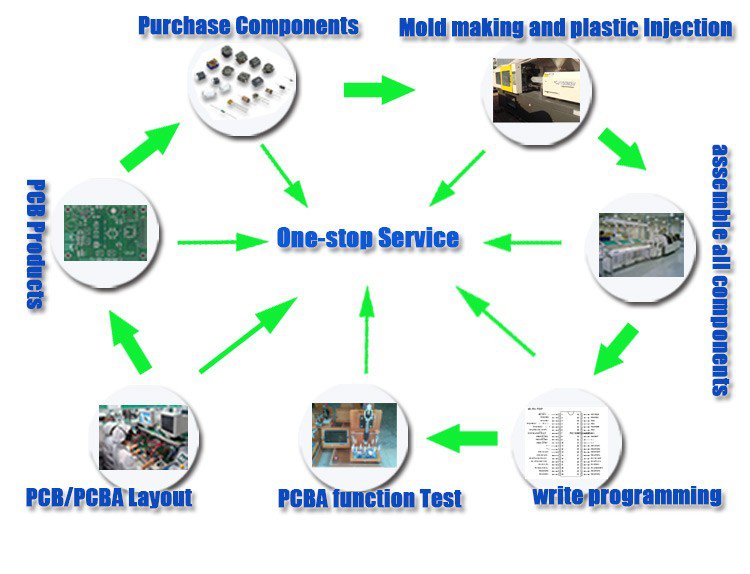

1. who are we?

We are based in Guangdong, China, start from 2006,sell to North

America(30.00%),Southeast Asia(20.00%). There are total about

51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

PCB,PCBA

4. why should you buy from us not from other suppliers?

We have a professional team with more than 10 years of experience

per capita, with advanced manufacturing equipment in the industry,

high quality, high efficiency, high service is our concept.

5. what services can we provide?

Accepted Delivery Terms: FOB,EXW;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,Credit Card,PayPal,Western Union;

Language Spoken:English,Chinese

1: On turn-key PCBA project, what does JPT do about part crossing

or substitutions?

First of all, we check your Bill of Materials (BOM), and send you

BOM with the brand we chose for each component and also we will

mark the components in different color to tell youwhich components

we chose the substitutions. We will give you advice on how to

reduce BOM costs by parts crossing or substitutions, but all part

changes are your own final decision.

2: How do you order components for Turn-Key orders?

We usually order 3‰ or 5 spare parts (depending on size and cost)

to accomplish your order without missing parts or shortages due to

Production Loss. If we encounter any Issues With BOM Components,

such as a large minimum order for a certain part, we will

communicate with you to find the best solution.

3: What is the lead time on a turn-key order?

The overall project Lead Time is the sum Parts Procurement lead

time and PCB Assembly lead time. However, we try to shorten the

time line by streamlining our PCB Assembly Process. For instance,

once we receive your Gerber Files for PCB Fabrication and BOM for

PCB Assembly, we will start to prepare the stencil for your board

and complete the fabrication concurrently with the parts

procurement process.

4: Is there a minimum order size for turn-key orders?

No. We have no restrictions on your order size; however, larger

orders are more cost effective. We can work with you to find a good

solution for your specific needs in cost reduction.

5: What happens to the leftover components on Turn-Key orders?

We can keep your leftover parts in our inventory for your next

order if you think these parts will be used again; otherwise, we

can ship spare parts with your completed order so you have access

to them for troubleshooting and repairs.

6: What do I need to send for a turn-key order?

* Bill of Materials, complete information in excel format. This

document should include manufacturer names, part numbers, Reference

Designators, component descriptions, and quantities.

* Gerber Files

* Centroid Data (AKA Pick and Place or XY-Coordinate Data)

* Other requirements or assembly instructions if applicable

7: Can you handle lead-free builds?

Yes, we have 12 lines for Lead-Free PCB Assembly.

8: Do you X-ray BGAs?

Yes. We also use X-Ray Inspection for any lead-less IC pins and

other parts that have leads which cannot be seen with a

microscope.

9: How do I need to supply my components?

* Each bag, tray, etc. should be clearly marked with the part

number, reference designators that is listed on your bill of

materials.

* Components which are sensitive to moisture or static must be

packaged in compliance with their storage requirement.

* SMT components provided must be sealed tightly or taped firmly.

Sending them loose may cause components damage and the production

delay.

|