| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Meltblown Fabric Production Line |

|---|---|

| Brand Name: | Chuzhou HH non-woven |

| Model Number: | SMS SMMS SSMMS S SS SSS |

| Certification: | CE |

| Place of Origin: | Chuzhou China |

| MOQ: | 1 set |

| Price: | negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | For detailed talk |

| Delivery Time: | For detailed talk |

| Packaging Details: | wood box packaged , machine wrapping with PE film keep cargo safe |

| Product Name: | SXS SMXS Meltblown Fabric Production Line |

| Screw L / D: | 30 : 1 |

| Average energy consumption: | 1000 - 1500 KWH |

| certificate: | CE ISO |

| advanced design: | flexible |

| Condition: | New |

| Filament denier: | 1.8 - 2.5 Denier |

| Bearing: | TMK |

| Company Info. |

| Chuzhou HH Non Woven Technology CO.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

Flexible design SXS SXXS SMXS SMXXS Spun Bond Meltblown Face Mask NonwovenFabric Meltblown Fabric Production line

The SXS SXXS SMXS SMXXS ( X means the position for upgrading by installing S or M beam in the future ) are also popular for many customers .

| QTY of Die | GSM ( g / ㎡ ) | Effctive width ( mm ) | Output ( t / y ) | Max speed (mm) | Embossing pattern |

S: 3sets M : 1 set / 2 set | 8 - 150 | 1600 | 7000 | 600 | Diamond , Sesame |

| 2400 | 10000 | ||||

| 3200 | 13000 |

Technical Advantages

1) The whole line is well-structured and easy to operate.

2) The whole line is highly automated.

3) Control elements are of well-know make, high performance and

reliable technologies.

4) The whole line are controlled by PLC and operated with

touch-screen.

5) The allocation of the main frame and auxiliary equipment can be

special designed and adjusted according to customers requirement.

Spinning die-head adopts design optimization of flow models of

coat-hanger type, equality distribution of melt, balance pressure

Non-broken or combine fibre no holes no blind angle, and fastly

Color transition. Rolling mill adopts DC motor universal joint

transfer,

Roller adopts technology of Ultra Laser Drilling to ensure the same

of the temperature,

No Hair-in filling. The equipment adopts cutting on line, automatic

low winding technology, in order to serve

Resource, and improve the production efficiency.

| Machine Model | Reifenhauser Reicofil 3/4,Spunbond lines, spun-melt lins S, SS,SSS, SXS,SXXS,SMMS ,SMS ,SSMMS |

| Machine Size | 18m-60m(L)*10m-31m(W)*10m-12m(H) |

| Raw Material required | PP(polypropylene),additives MFI/MFR:25-40g/10min(spunbonding process) MFI/MFR:800-2000g/10min (Melt-blowning process) |

| Effective width | 1600mm,2400mm,3200mm,4000mm,4800mm customizable width by requirements |

| Max Speed | 150m/mn-550m/min |

| Transformer&Power consumption | Transformer require:200KVA-3000KVA Power consumption :500KWH/Ton-1400KWH/Ton |

| Output per year | 1500 Tons - 10000 Tons |

| Products GSM | 8gsm-250 gsm |

| Applications of products | Industrial:Shopping bags, furniture ,agriculture ,packageing,etc Medical:Surgical gown /cap /sheet /mask ,etc Hygiene: Diapers ,sanitary ,napking , etc. |

1 SSMMS SMMS SMS DATA SHEET

ssmms data

| Working width | Fabric | Power input | Consumption | Annual output/Year |

| 1600mm | 9-80G/㎡ | ≈1600KVA | 1700º-1900º/Ton | 6200T |

| 2400mm | 9-80G/㎡ | ≈2000KVA | 1700º-1900º/Ton | 8000T |

| 3200mm | 9-80G/㎡ | ≈3000KVA | 1700º-1900º/Ton | 11000T |

| 4200mm | 9-80G/㎡ | ≈3500KVA | 1700º-1900º/Ton | 14000T |

| 4800mm | 9-80G/㎡ | ≈4000KVA | 1700º-1900º/Ton | 16000T |

smms data

| Effective width(mm) | 1600 | 2400 | 3200 | 4000 | 4800 |

| Output(ton/year) | 4000T | 6200T | 5400T | 10500T | 12700T |

| GMS Range(g/㎡) | 9-100 | 9-100 | 9-100 | 9-100 | 9-100 |

| Max.speed(m/min) | 450 | 450 | 450 | 450 | 450 |

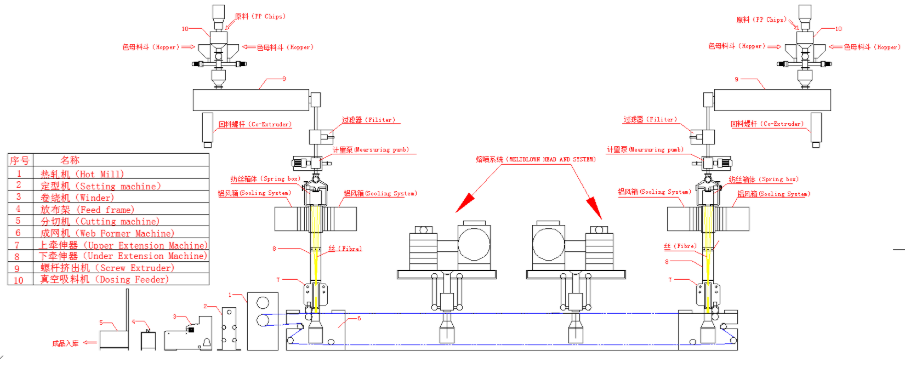

2. Process flow

Parts of spunbonded nonwoven fabric production line:

Recycle extrude→Main extruder→Filter→Metering pump→Monomer suction device→spinning box( Changzhou/ENKA/KASEN spinneret )→Quenching air chamber→stretching device→Web former→Calender→Winder→Slitter

Spunbonded process and technical flow chart:

Additive(Recycling off-cut fabric)→Raw material→Melting→Filtering→Measuring→Spinning→Cooling→Stretching→Web forming→Calendering→Winding→Cutting→Final product

Parts of Melt blown nonwoven fabric production line:

Main extruder→filter→Metering pump→Air heating system→Melt blown sprayer (ENKA sprayer)→Web former→Winder→Slitter

Melt blown process and technical flow chart:

Raw material →Melting→Filtering→Measureing→Air heating→Spraying→Web forming→Winding→Cutting→Final product

Additive (recycle edge)

↓

Material → melting and extruding → filtering → metering → spinning

→ quenching → air-flow drawing → web forming → calendaring →

winding and slitting

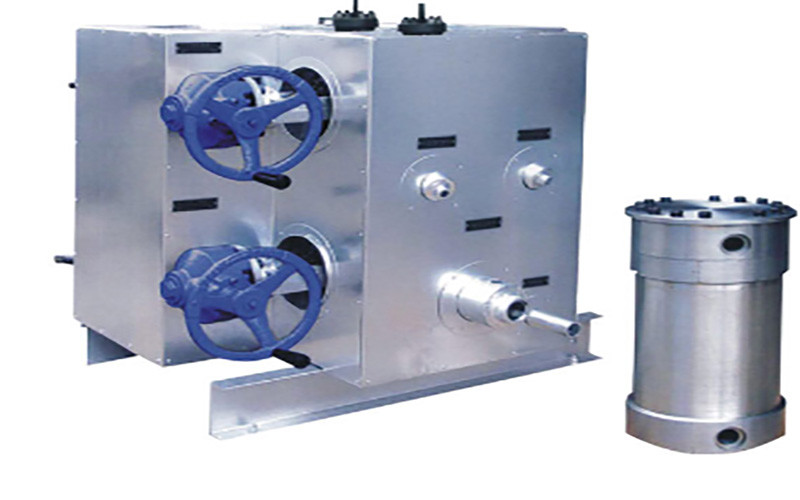

3 Key component

Name:Main Extruder Brand:HHM Original:China Diameter:Φ135mm for 1.6m,Φ170mm for 3.2m,Max speed: 75r/min for 1.6m , 85r/min for 3.2m Motor:90kw for 1.6m , 132kw for 3.2m

Name:FilterBrand:HHMOriginal: ChinaType: Hydraulic or Candle filterFilter precision: 45μm~60μmFitration area: 2.5 m2for 1.6m,3.5 m2 for 3.2m

Heat source : heat-transfer oil , circular heating

Name: Spinning Box Orificenumber:11019for1.6m17651for3.2mOrificediameter:Φ0.45mmL/D=4:1Max temperature:300℃

Fuction : for spining the PP flament.

| Name | Spinning box |

| Orifice number | 1109 for 1.6 m , 17651 for 3.2 m |

| Orifice diameter | ¢0.45mm L/D 4 : 1 |

| Max temperature | 300℃ |

| Fuction | For spinning the PP flow |

Draft divice , including up draft and down draft .spinning allows the thread to reach the right thickness through preciss drafting devices.

.

SLitter cutter & Winder machine is used to have made the non woven finished products into the packaging equipment

4 High - accuracy CNC center keep S SS SMS SSMMS non woven making line beyond customer requriement .

5 Shipping and packing

Machine Nude packing , wooden case is optional , case packing , ecletric parts carton box or wooden case packaged , other machines nue packaging wrapping with PE film keep cargo safe.

6 Why choose us?

1. High standard nonwoven machine specification.

2. Free inspection invitation before delivery.

3. your order safe and your money is safe.

4. Free door to door engineering service in 24 month.

5. CE Certification and ISO:9001 management system.

|