| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Spunbond Nonwoven Fabric Machine |

|---|---|

| Brand Name: | Chuzhou HH non-woven |

| Model Number: | HHM - SS SSS |

| Certification: | CE |

| Place of Origin: | Chuzhou China |

| MOQ: | 1 set |

| Price: | negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 3 line / months |

| Delivery Time: | 90 - 150 days |

| Packaging Details: | components wood box packaged , machine wrapping with PE film keep cargo safe |

| Cargo: | tripoe spunbond nonwoven fabric machine |

| Annual output: | 8000 - 15000 ton |

| filament Denier: | 1.8 - 2.5 D |

| Size: | follow customer |

| roll dia: | 1200 mm |

| power consumption: | 600 - 800 KW*H |

| Max speed: | 550 m / min |

| method: | spunbond air drawing |

| Company Info. |

| Chuzhou HH Non Woven Technology CO.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

cost effective China non woven fabric SSS melt blown cloth production making machine

Technical Parameters

| Model | HHM-1.6 SSS | HHM-2.4SSS | HHM-3.2SSS | HHM-4.0SSS | HHM-4.8SSS |

| Effective width | 1.6M | 2.4M | 3.2M | 4.0M | 4.8M |

| Weight range | 10-120g/m2 | 10-120g/m2 | 10-120g/m2 | 10-120g/m2 | 10-120g/m2 |

| Out put per day | 12-17Ton | 16-21Ton | 24-29Ton | 28-33Ton | 32-37Ton |

| Machine speed | ≦400/min | ≦400/min | ≦400/min | ≦400/min | ≦400/min |

| Transformer capacity | ≦500KVA | ≦750KVA | ≦900KVA | ≦1100KVA | ≦1300KVA |

| Power consumption | 650º-700º/Ton | 650º-700º/Ton | 650º-700º/Ton | 650º-700º/Ton | 650º-700º/Ton |

| Machine Size(L*W*H) | 30m*17m*12m | 30m-24m*12m | 30m*31m*12m | 30m*38m*12m | 30m*45m*12m |

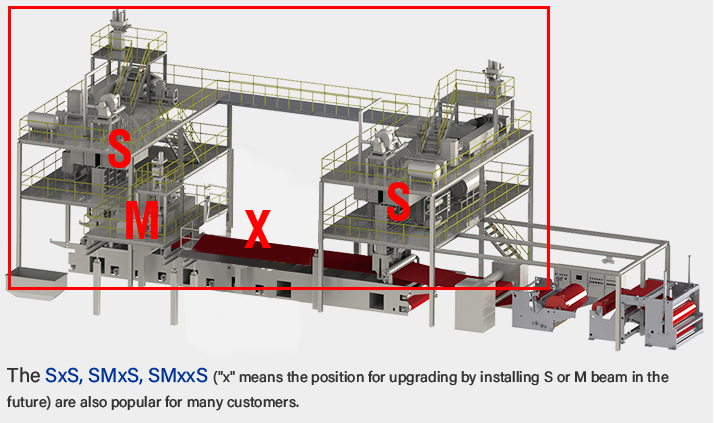

| Machine Model | Reifenhauser Reicofil 3/4,Spunbond lines, spun-melt lins S, SS,SSS, SXS,SXXS,SMMS ,SMS ,SSMMS |

| Machine Size | 18m-60m(L)*10m-31m(W)*10m-12m(H) |

| Raw Material required | PP(polypropylene),additives MFI/MFR:25-40g/10min(spunbonding process) MFI/MFR:800-2000g/10min (Melt-blowning process) |

| Effective width | 1600mm,2400mm,3200mm,4000mm,4800mm customizable width by requirements |

| Max Speed | 150m/mn-550m/min |

| Transformer&Power consumption | Transformer require:200KVA-3000KVA Power consumption :500KWH/Ton-1400KWH/Ton |

| Output per year | 1500 Tons - 10000 Tons |

| Products GSM | 8gsm-250 gsm |

| Applications of products | Industrial:Shopping bags, furniture ,agriculture ,packageing,etc Medical:Surgical gown /cap /sheet /mask ,etc Hygiene: Diapers ,sanitary ,napking , etc. |

M Model

| Working width | Fabric | Power input | Consumption | Annual output/Year |

| 1600mm | 15-300G/㎡ | ≈600KVA | 3000º-3500º/Ton | 800T |

| 2400mm | 15-300G/㎡ | ≈800KVA | 3000º-3500º/Ton | 1100T |

| 3200mm | 15-300G/㎡ | ≈1000KVA | 3000º-3500º/Ton | 1500T |

SMS Model

| Working width | Fabric | Power input | Consumption | Annual output/Year |

| 1600mm | 9-100G/㎡ | ≈800KVA | 1300º-1600º/Ton | 3200T |

| 2400mm | 9-100G/㎡ | ≈1250KVA | 1300º-1600º/Ton | 5100T |

| 3200mm | 9-100G/㎡ | ≈1600KVA | 1300º-1600º/Ton | 7000T |

| 4000mm | 9-100G/㎡ | ≈2000KVA | 1300º-1600º/Ton | 8700T |

| 4800mm | 9-100G/㎡ | ≈2250KVA | 1300º-1600º/Ton | 10500T |

SMMS Model

| Working width | Fabric | Power input | Consumption | Annual output/Year |

| 1600mm | 9-100G/㎡ | ≈1500KVA | 1700º-1900º/Ton | 4000T |

| 2400mm | 9-100G/㎡ | ≈1600KVA | 1700º-1900º/Ton | 6200T |

| 3200mm | 9-100G/㎡ | ≈2200KVA | 1700º-1900º/Ton | 8400T |

| 4000mm | 9-100G/㎡ | ≈2500KVA | 1700º-1900º/Ton | 10500T |

| 4800mm | 9-100G/㎡ | ≈2630KVA | 1700º-1900º/Ton | 12700T |

SMMMS Model

| Working width | Fabric | Power input | Consumption | Annual output/Year |

| 1600mm | 9-80G/㎡ | ≈1600KVA | 1700º-1900º/Ton | 6200T |

| 2400mm | 9-80G/㎡ | ≈2000KVA | 1700º-1900º/Ton | 8000T |

| 3200mm | 9-80G/㎡ | ≈3000KVA | 1700º-1900º/Ton | 11000T |

| 4200mm | 9-80G/㎡ | ≈3500KVA | 1700º-1900º/Ton | 14000T |

| 4800mm | 9-80G/㎡ | ≈4000KVA | 1700º-1900º/Ton | 16000T |

Description Of Non-woven Machine

1) Parts of spunbonded nonwoven fabric production line:

Recycle extruder---->Main extruder---->Filter---->Metering

pump---->Monomer suction device--->Spinning box(ENKA/KASEN

spinneret)---->

Quenching air chamber---->Stretching device---->Web

former---->Calender---->Winder---->Slitter

2) Spunbonded process and technical flow chart:

Additive(Recycling off-cut fabric)---->Raw material---->

Melting---->Filtering---->Measuring

---->Spinning---->Cooling---->Stretching---->

Web forming---->Calendering---->Winding---->

Cutting---->Final product

Description Of Non-woven Machine

1) Parts of spunbonded nonwoven fabric production line:

Recycle extruder---->Main extruder---->Filter---->Metering

pump---->Monomer suction device--->Spinning box(ENKA/KASEN

spinneret)---->

Quenching air chamber---->Stretching device---->Web

former---->Calender---->Winder---->Slitter

2) Spunbonded process and technical flow chart:

Additive(Recycling off-cut fabric)---->Raw material---->

Melting---->Filtering---->Measuring

---->Spinning---->Cooling---->Stretching---->

Web forming---->Calendering---->Winding---->

Cutting---->Final product

Main part of Nonwove system

Candle filtration Machine

Filtration Area: 3.5m²; Capacity: 650kgs/h; Filtration Chamber: 2 pcs (switch online); Original:CHINA;

Spinning Pump

Capacity:300-450Kg/H; Speed:40Rpm/Minute; Drive Motor:Siemens; Original: CHINA/GERMANY

Automatic Slitting Machine

Speed:600-800 M/Minute; Min. Slitting width:80mm; Max. Rolling size:1500mm diameter; Auto tensile control:online; Auto meter counting:online; Original:CHINA;

Raw Material Dosing Machine

Weight system: by weight; Hopper : 4 pcs; Accuracy:0.01%; Feeding Percentage: 1-99%; Original:USA/ITALY;

Precisely CNC center hold machining parts beyond custmer request .

Exhibition show with customer

PACKING PROCESS

We use a double packaging process of plastic and wood :first , we pack the machine parts i plastic so that they are protected from air and ranin , oxidaton or rust . The second part is packed with hard wood to weal the box , to avoid collision deformation , so that the machine handed over to you in good condition as new !

How to start the Nonwoven fabric manufacturing business ?

All potential buyers should check below factors if you want to produce nonwoven fabrics .

Our Advantages

Our Strengths:

1.Quality Control in whole process, provide individual high cost-effective nonwoven lines, helping customer cost saving.

2.Focus on non woven equipment research and development in 14 years. Install and running more than 400 lines all over the world.

3.Import high precision CNC machine from Japan. The key parts machining in house, ensure to provide high quality machine for each customer.

4.Over 20 person team for machine after sales service.Ensure the customers can get quickly and professional installation and debugged in time.

Why choose us

1.Machine Inspection

We warmly welcome the customer to come our factory to inspect the

production line before delivery . The machines only be delivered

when the you accept the quality of the machines and the product.

2.Installation and training

Once we finalize the production and delivery,we will assign 3lots

about 4-7 professional engineers both in mechanical and electrical

parts to the buyer’s factory for installation and samples test .

And the engineers will also train some skilled workers for buyer.

The seller will explain, operate and analyse in theory on the spot

until the customer can operate the equipment himself. The customer

can consult with the seller at any moment if they don’t understand.

If you have difficulties or faults that can not be resolved by

themselves during the practical production, we will offer relative

technology immediately or assign workers to resolve the

problems on the spot.

|