| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Conveyor Belt Splicer |

|---|---|

| Brand Name: | Running Machine |

| Model Number: | ZLJ-1600*830 |

| Certification: | CE/ISO |

| Place of Origin: | China |

| MOQ: | 1 Set |

| Price: | $9500 ~ $ 10500 / set |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram, D/A, D/P |

| Supply Ability: | 500 Set/ M |

| Delivery Time: | 7 days |

| Packaging Details: | Wooden Box |

| Material: | Aluminum Alloy |

| HS Code: | 84778000 |

| Type: | Hot Splicing Type |

| Usage: | Conveyor Belt System |

| Cooling System: | Water Cooling System |

| Heating-up Time: | 30 Mins |

| Vulcanizing Temperature: | 145ºC |

| Warranty: | 2 Years |

| Company Info. |

| Qingdao Running Machine Co.,Ltd |

| View Contact Details |

| Product List |

1600mm Lightweight Conveyor Belt Splicer with Aluminum Structure

Vulcanization — the use of heat, time and pressure to re-splice a belt — is the most reliable conveyor belt repair method, as it creates the highest return to original belt strength. So the choice of conveyor belt splicer is very important.

SECTIONAL CONVEYOR BELT SPLICER

New type Vulcanizing Press with E type cross beam, one kind of heavyweight vulcanizer, use new design components, include flexible pressure bag, traverse bars with standard heating platen and controller. Learn from Canada brand similar products.

TECHNICAL PARAMETERS

Model | Size of heating board: L×W (mm) | Width for jointed rubber belt (mm) | Total power (kw) | Max. weight of component (kg) | Measurement: L×W×H (mm) | Total weight (kg) | Equipped device | |

| Manual pump | Electric control box | |||||||

| EPN-650 | 830×838 | 650 | 4 | 45.5 | 1142×830×750 | 445 | 1 | 1 |

| EPN-800 | 830×1028 | 800 | 7.2 | 53.8 | 1320×830×750 | 550 | 1 | 1 |

| EPN-1000 | 830×1188 | 1000 | 8.4 | 60.5 | 1440×830×750 | 625 | 1 | 1 |

| EPN-1200 | 830×1458 | 1200 | 10.8 | 69.3 | 1680×830×750 | 795 | 1 | 1 |

| EPN-1400 | 830×1638 | 1400 | 11.4 | 78.8 | 1950×830×750 | 911 | 1 | 1 |

| EPN-1600 | 830×1808 | 1600 | 13.2 | 89.7 | 2060×830×980 | 1056 | 1 | 1 |

| EPN-1800 | 830×2078 | 1800 | 15 | 98.3 | 2320×830×980 | 1198 | 1 | 1 |

| EPN-2000 | 830×2328 | 2000 | 16.8 | 107.4 | 2582×830×980 | 1315 | 1 | 1 |

| EPN-2200 | 830×2508 | 2200 | 18 | 130.5 | 2842×830×980 | 1422 | 1 | 1 |

| EPN-2400 | 830×2638 | 2400 | 19.5 | 140 | 2950×830×980 | 1500 | 1 | 1 |

| EPN-2600 | 830×2828 | 2600 | 21.8 | 150 | 3128×830×980 | 1628 | 1 | 1 |

Note:

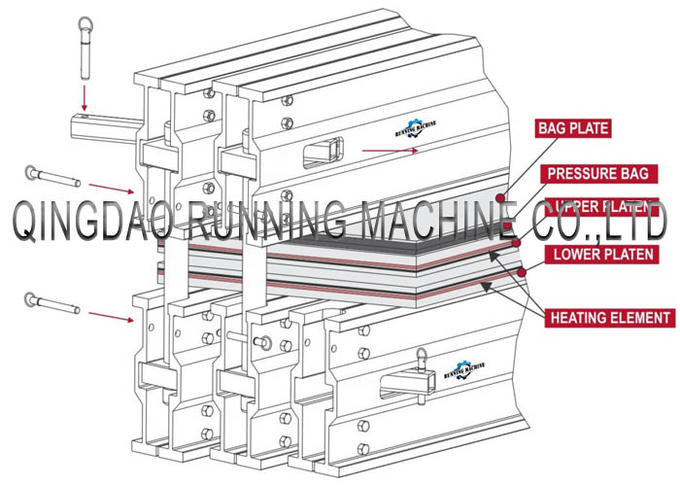

COMPONENT OF RUBBE CONVEYOR BELT SPLICER MACHINE

The Rubber conveyor belt splicer machine consists of Aluminum beam, plywood board, heating platen, water cooling platen, water pressure bag and electricity control cabnient.

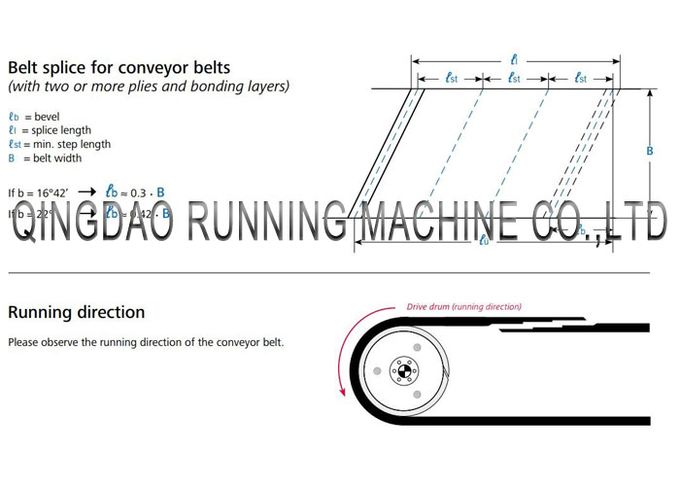

RUBBER CONVEYOR BELT SPLICING INSTRUCTION

Usually we provide the packing list as following:

| #1 | Heating plate with build in water cooling device | 2 Pieces | |

| #2 | Almex type pressure bag | 1 Pieces | |

| #3 | Heating insulation plate | 3 Pieces | |

| #4 | Standard Control Box | 1 Sets | |

| #5 | Cross Beams | as vulcanizer | |

| #6 | Ratchet wrench | 2 Handles | |

| #7 | Primary wire/cable with plugs 10 meters | 1 Pieces | |

| #8 | Secondary wire/cable with plugs 5 meters | 2 Pieces | |

| #9 | Electric pump | 1 Set | |

| #10 | High pressure hose | 15Mpa 5 Meters | |

| #11 | Clamp bolt, Nut, Gasket | 10 sets | |

| #12 | Clamp Device (optional) | As request | |

SHIPPING PACKAGE of conveyor belt splicer

|