| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Sieve Bend Screen |

|---|---|

| Brand Name: | STD Filter |

| Model Number: | STD SBS-022 |

| Certification: | CE,ISO9001 |

| Place of Origin: | Hebei,CN |

| MOQ: | 1 |

| Price: | $50-500 /pcs |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 1 pcs per day, |

| Delivery Time: | 7 days or customized time |

| Packaging Details: | plastic in wooden package or standard export package |

| shape: | square or round or material curved |

| Length: | 2 meters or as required |

| Width: | 1 meter or customized |

| Diameter: | 1 meter or customized |

| Type: | separation,Filtrating |

| Feature: | Corrosion Resistance |

| Usage: | Sieve |

| Technique: | Welding |

| Application: | Industrial filtration |

| Filter rating: | 99% |

| Slot size: | 0.1-6.0 mm |

| Material: | Stainless Steel316,304,AISI 304,316. SUS 304 or 316 |

The Introduction

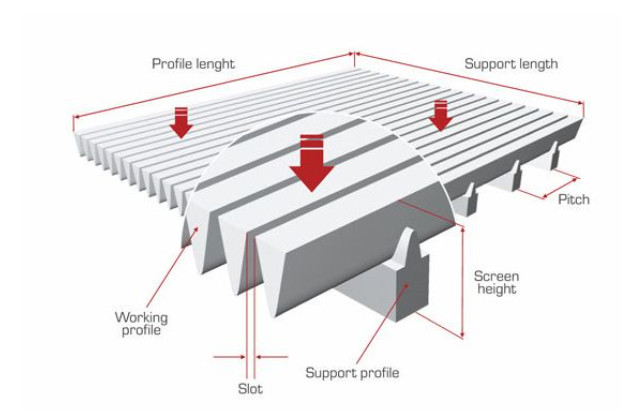

The contour screen, also known as the wedge line, v line, and Triwire, is customized for your application.The characteristics of this type of sieve make it an attractive solution for separating solids from liquid, retention media, filtration, application of glue, dehydration, collection and distribution.

The profile screen provides widening inward so that particles can

pass through the sieve and reduce blinding.

Profile wire screens were originally produced as hydraulic

cylinders or flat plates.Both manufacturing methods have their own

characteristics and advantages.

The line (size and shape) are selected according to the opening

area.Blind consideration and wear-life factors.

The profile wire screen is usually made of Type 304 stainless

steel, although other alloys are available.Type 316 stainless steel

can be used for saline units.High manganese steel profile wire is

used for abrasive applications such as mineral processing, fully

welded stainless steel.The structure has high strength and extended

service life.

Mineral ation, coal preparation and gold recovery.The sieve bend is a cross-flow sieve.The contour line is slightly inclined to make the leading edge position higher, greatly increasing the dehydration capacity.

The Features:

Screening and bending processing in solid / liquid separation:

Solid-containing liquid (or slurry) is poured into the feed tank

and spilled onto the sieve.The sharp leading edge of each wedge

wire cuts off a thin layer of water and a small granular

solid.Larger particles continue facing down the sieve until most of

the liquid is removed.The size of the separated particles depends

on the size of the coal particles and their settling rate in the

liquid.

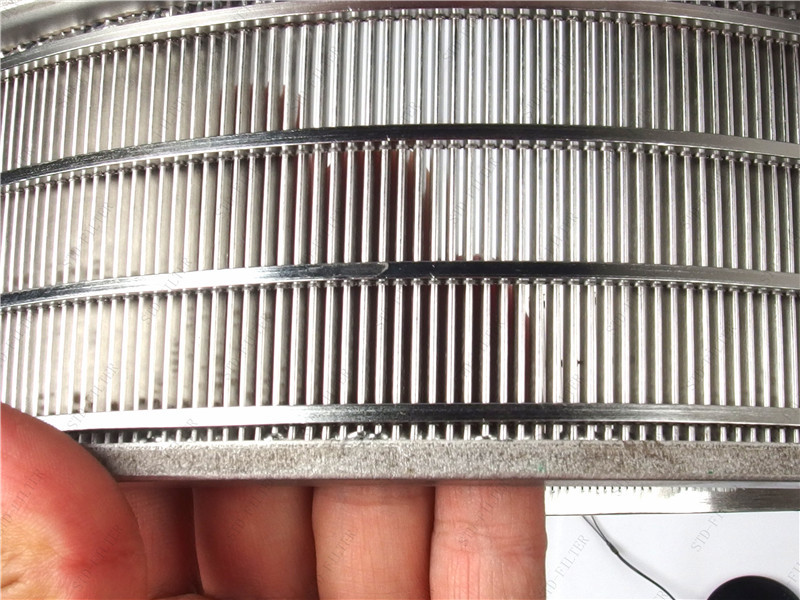

Characteristics: The welded stainless steel water well screen is made up of rods

and warp. The rod can be round wire, triangular wire or trapezoid

wire. The warp is triangular wire (V-shaped wire). Water well

screens have a structure and high open area, as well as accurate

slot dimension. At the same time, water well screen have

heat-resisting, anti-corrosive, good machine capability, last long,

safety and reliability and so on characteristics. It can be used in

many kinds of medium filtering.

Uses: The strainer is a kind of filtered water tubing with the

perforation. It can be used with the deep well pump, dive water

pump, water-treatment equipment, environmental protection, sea

water transforming into the industrial water treatment and life use

water desalination treatment, running water treatment, water

softening treatment and the petroleum industry. It can also be used

as petroleum product terminal filters, chemical acid, the alkali

liquid filters, ethyl alcohol and organic solution recycling

filters, etc.

Features of products

Welwire diameter: 0.300 mm.Material: 304 stainless steel.Other items are as follows:

| Profile Wire Width | Relief Angle | Typical Support Rod |

| 1/16”(.063”) | 13 degrees | Small round rod |

| 3/32”(.093”) | 13 degrees | Round or Rectangular bar |

| 1/8” (.125”) | 13 or 5 degrees | Round or Rectangular bar |

The Usage accasions:

The features of the Wedge Wire screen make it an attractive

solution for separating solids from liquids, retaining media,

filtering, sizing, dewatering, collecting, and distributing.

Some of the applications where profile wire screens can be found

include, but not limited to the following:

Corn Wet Milling

Malting Processes

Winery Processes

Sugar Processes

Brewing Processes

The Details

The Package:

The Delivery

Please Meet us on The http://www.wedgefilter.com

|