| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Trailer Air Springs |

|---|---|

| Place of Origin: | Guangdong, China |

| Brand Name: | VKNTECH |

| Certification: | IATF16949/ISO9000 |

| Packaging Details: | CARTON/PALLET |

| Supply Ability: | 2000000pcs/Year |

| MOQ: | 20 Pieces |

| Price: | $1.00 - $50.00/Pieces |

| OE NO.: | 1T19ZK-5.7 |

| Warranty: | 12 Months |

| Type: | by sea / by air / by truck |

| Car Model: | For bus/truck&trailer |

| Material: | Imported Natrul Rubber |

| Operation: | Gas-filled |

| Brand: | VKNTECH or customized |

| Service offered: | OEM |

| Price condition: | FOB China |

| Sample: | Available |

| Suspension system: | Air Spring Suspension |

| Type of Goods: | Air Spring/Air bags/Air Ballons |

| Package: | Standard packing or customized |

| Payment term: | T/T&L/C |

| Port: | Guangzhou |

| Company Info. |

| Guangzhou Viking Auto Parts Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

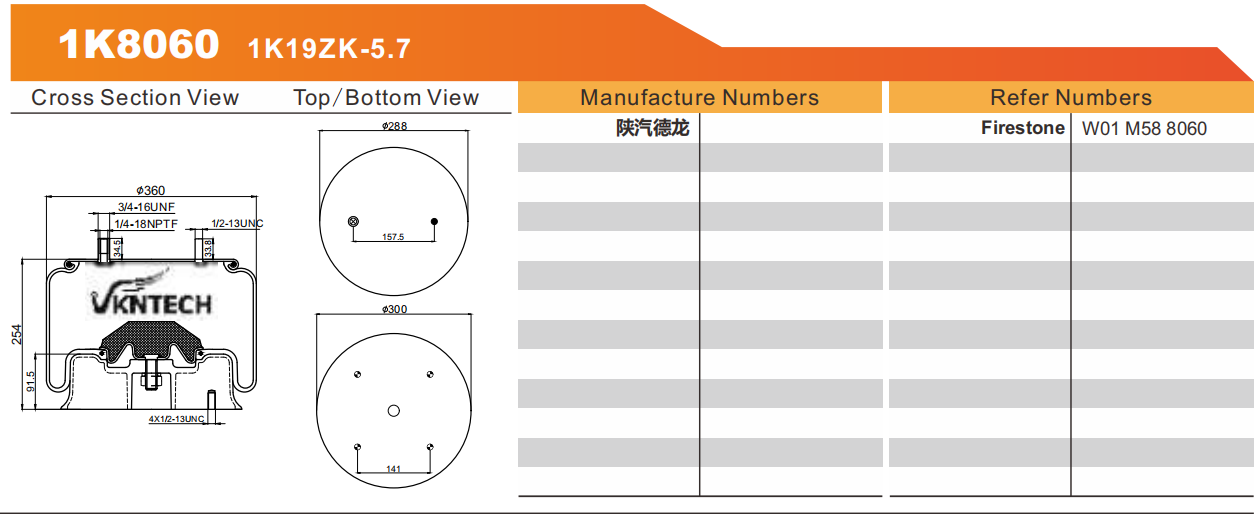

Truck And Trailer Air Suspension Spring/1T19ZK-5.7 Air Ride Suspension 1T19J-6 ET19J-6 DZ95259440308

Product Description

| Part number | 1K 8060 |

| OEM numbers | 1T19ZK-5.7 T19J-6 DZ95259440308 |

| Working tempreature | -40°C bis +70°C |

| Failure testing | ≥3 millions |

Product picture

Maintenance of the air springs, Vehicle Check-List

Air Spring Installation

Important tips to remember when installing a new unit

|