| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Skived Fin Heat Sink |

|---|---|

| Brand Name: | FODOR |

| Model Number: | HEAT SINK-S0002 |

| Certification: | ISO9001:2015 |

| Place of Origin: | China |

| MOQ: | 100PCS |

| Price: | EXW/FOB/CIF/DDP |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 30000 PCS Per month |

| Delivery Time: | 20-30days |

| Packaging Details: | Blister packaging |

| Raw Material: | AL6063-T5 |

| Surface Treatment: | Anti-oxidation |

| Application: | Copper Skived fin heat sink |

| Processing Service: | Cutting, CNC, Anodizing |

| Delivery time: | 20-30days |

| Keyword: | skived fin heat sink |

| Company Info. |

| Dongguan Fodor Technology Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

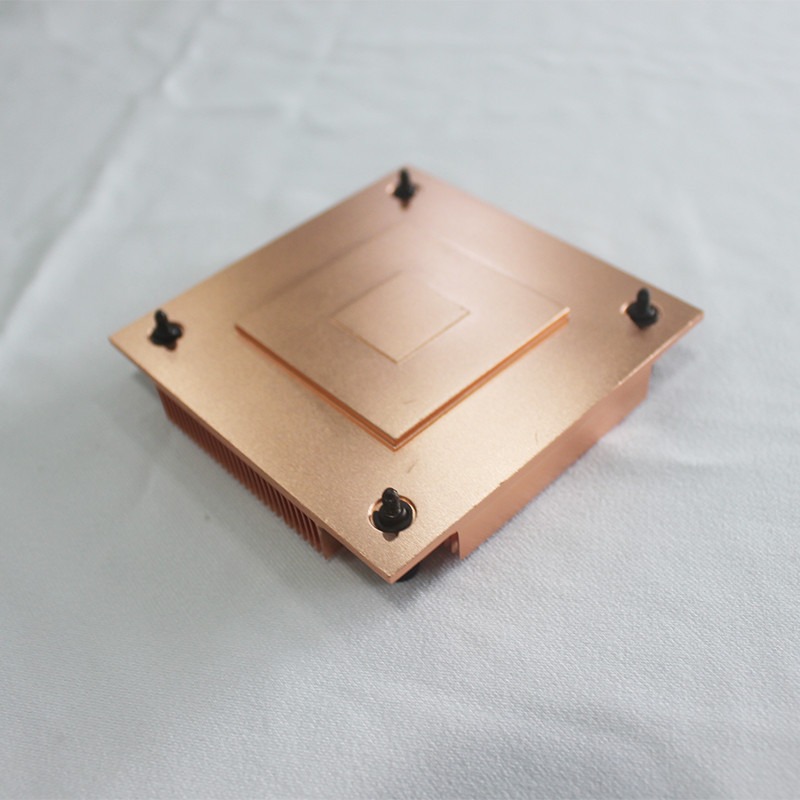

Premium Versatile Copper Skived Fin Heat Sink With ISO9001-2015

Quick Detail

| Raw Material | Copper |

| Custom Service | Yes, OEM/ODM Service |

| Quality System | ISO9001:2015 |

| Processing Technology | CNC Gear /Wood machining/CNC/Riveting |

| Surface treatment | Anti-oxidation |

| Packing Way | Blister packaging or special packing you would like |

| Application Scenario | Electronic equipment heat sink |

| MOQ Request | 100/500/1000 |

Description

This heat sink is based aluminum profile 6063-T5 material to processing, first of all, we check the raw material dimension is fine or not, the second is that according to the drawing, use the CNC Gear shovel machine to do the dimension, the third is that accroding to the drawing, the forth is that use the CNC to do exact dimension, the fifth is do anodizing clear, the last step is riveting, and then inspection/packing. First inspection and patrol inspection are done in processing.

Notes

This is a skived fin heat sink

Skived Fin Heat Sinks offer highly optimized cooling as they allow for higher fin densities than what is manufacturable using extrusion methodologies, but do not have an interface joint that restricts heat flow like bonded or brazed fin heat sinks. Unlike bonded or brazed heat sinks, Skived Fin Heat Sinks are constructed from a single piece of material and offer reduced thermal resistance since there is no joint between a base and fins. These heat sinks are manufactured by precisely slicing the top of the base, called skiving, folding it back to where it is perpendicular to the base, and repeating at regular intervals to create fins.

Fodor can offer copper skived fi heat sink and aluminum(AL1050/6063) skived fin heat sink.

|