| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Glass Batch Plant |

|---|---|

| Brand Name: | JEFFER |

| Model Number: | Customized |

| Certification: | ISO9001, ISO14001, ISO45001 |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 1 set per 2 months |

| Delivery Time: | 60 days after received the down payemnt |

| Packaging Details: | Wooden case, steel frame, tray...... |

| Name: | Glass Batch Plant |

| Application: | Glass industry |

| Usage: | Raw Material Treatment |

| Place of origin: | China |

| Voltage: | 380V, 50Hz |

| Capacity: | Customized |

| Warranty: | 1 year |

| Motor power: | Accordingly |

| Company Info. |

| JEFFER Engineering and Technology Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

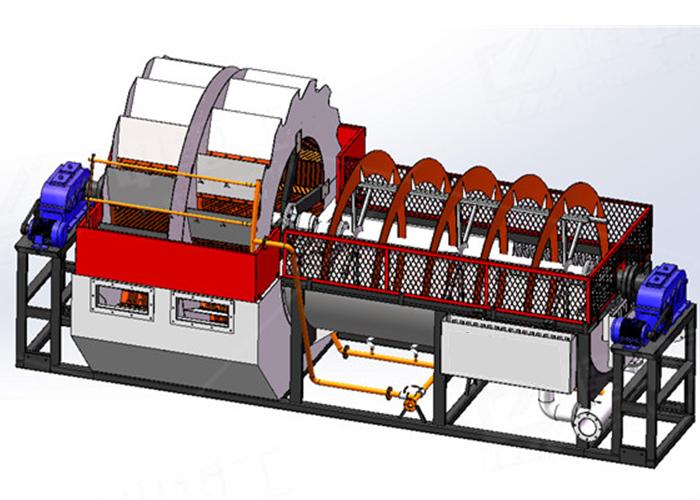

Large Capacity Glass Batch Plant High Efficiency Raw Material Treatment

1. Brief introduction

In order to improve the production efficiency, if the granularity composition of raw materials can not meet the physical-chemical properties and processing property of glass product, the raw materials will be required to be pretreated before batching.

Reasonable granularity composition of raw materials can reduce the chemical component fluctuation to the lowest limit and increase the mixing homogeneity of batched glass materials, which is beneficial to improve the melting rate of the materials and homogenizing speed of glass liquid.

2. Main type of raw materials

| Item | Description |

| 1 | Silica sand |

| 2 | Feldspar |

| 3 | Dolomite |

| 4 | Limestone |

| 5 | Soda ash |

3. Types of auxiliary materials

| Item | Description |

| 1 | Clarifying agent |

| 2 | Decolorizing agent |

| 3 | Coloring agent |

| 4 | Oxidizing agent |

| 5 | Cosolvent agent |

| 6 | Reducing agent |

4. Arrangement type of batch plant

Silos arrange on one line.

Material loading system is arranged on one line.

Mixer, scales and silos are vertically arranged.

The scales are connected with the mixer directly.

The material loading system for big capacities of batch need to

load the materials from various directions.

5. Material feeding device

6. Main equipment of batch plant

Simple structure

High crushing efficiency, energy saving and environment protecting.

It can crush medium hard and ultrahand materials, such as corundum, sintering bauxite.

Hindered settler is used for classifying silica sand or other mining coarse and fine particle, it adopts to classify the mineral with different gravity and replace the fine screen for force control.

There is a special device in the water tank under the cylinder bottom. When water outage, the water hole will close automatically, to avoid the materials in the cylinder blocking the hole and enter into the water tank.

Desiliming hopper also calls circular cone, it is a simple classification, desliming and thickening device.

Hydraulic classifier is a particle classifying unit and system equipment in mineral classifying professional area.

Bag-type dust collector is a kind of high-efficiency special purification equipment, which is suitable for the top of power plant ash warehouse, powder warehouse, etc.

Mixer is a kind of mechanical equipment that could mix two or more types of materials homogeneous together.

The bucket elevator consists of upper section, lower section, intermediate section, deriving section and operation section.

|