| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Geocell Confinement System |

|---|---|

| Brand Name: | Hengquan |

| Model Number: | Cell Height:50-250mm |

| Certification: | ISO 9001 |

| Place of Origin: | China |

| MOQ: | 1000m2 |

| Price: | 1usd/Squre meter, Other types need to Deliberation |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 40000 Squre meters per week |

| Delivery Time: | 5-8 days |

| Packaging Details: | packing belt |

| Name: | Geocell Confinement System |

| Transport Package: | Winding Tape |

| Weld Spacing: | 400mm |

| Keyword: | customer pay freight |

| Thickness: | 1.0mm |

| Surface: | Textured |

| Application: | Excellent Corrosion Resistance |

| Material: | HDPE |

| Package: | Plastic Packing Belts |

| Feature: | Corrosion Resistant, Oxidation Resistance, Chemical Stability, Wear-resistant |

Plastic HDPE Geocell for Retaining Wall 1.1mm-1.8mm

About Hengquan

We have experience for more than 7 years. There are two product lines for geogrid and geocell. Factory work 24hours a day, we sold more than 100,000,000rmb last year(2020). Our customers are all over the world.

Brief Introduction of Geocell Confinement System

In the early 1980s, the US Army Corps of engineers first used geocell and obtained a patent. The early use of this technology was to build military roads on soft soil. Today, Hengquan Geocell is not only used for foundation stability, but also for erosion control of slope and channel and construction of retaining wall.

Geocell Confinement System Characteristic

Geocell cellular confinement systems applications have many advantages. We may list these advantages as follows;

It allows the use of natural filling materials instead of expensive

filling materials in the application area.

In addition to being economical, it provides more than 50%

reduction in filling depth compared to classical methods.

Three-dimensional cells ensure the compression of the filling

material, increasing the bearing capacity and it prevents

collapses. It plays an important role in increasing the hardness

ratio of the structural filling and thus gains strength. Due to its

structure, it provides a natural drainage structure, while at the

same time it prevents the filling material from being damaged by

hydraulic flows.

Laying method

① Foundation treatment

Firstly, the lower layer shall be leveled and rolled. The flatness

shall not be greater than 15mm, and the compaction shall meet the

design requirements. Hard protrusions such as gravel and stones are

strictly prohibited on the surface.

② Laying geogrid

a. When storing and laying geogrids, avoid exposure and long-term

exposure to avoid deterioration of performance.

b. It shall be laid perpendicular to the line direction, overlapped

and firmly connected according to the requirements of the design

drawings. The strength of the joint in the stress direction shall

not be less than the design tensile strength of the material, and

its lamination length shall not be less than 20cm.

c. The quality of geogrid shall meet the requirements of design

drawings.

d. During construction, it is necessary to maintain continuity

without deformation, wrinkling and overlap. Pay attention to

tension the grid by hand to make it uniform and flat, close to the

lower bearing surface, and fix it with nails and other measures.

e. For the geogrid, the long hole direction is consistent with the

cross section direction of the line, and the geogrid shall be

straightened and leveled. The end of the grating shall be treated

according to the design.

f. After the geogrid is laid, the filler shall be filled in time at

an interval of no more than 48 hours to avoid direct exposure to

the sun.

③ Fill

After the grating is laid, it shall be filled in time. The filling

shall be carried out according to the symmetrical principle of "two

sides first and then the middle", and it is strictly prohibited to

fill the middle of the embankment. The filler shall not be unloaded

directly on the geogrid, but must be unloaded on the paved soil

surface, and the unloading height shall not exceed 1m. All vehicles

and construction machinery shall not walk directly on the paved

geogrid, but only along the embankment.

④ Rolling grating

After the first layer of filler reaches the predetermined thickness

and is rolled to the design density, roll the grid back for 2m,

bind it to the previous layer of geogrid, manually trim and anchor,

and plant 1m soil outside the rolling end to protect the grid from

human damage.

⑤ The laying of one layer of geogrid shall be completed according

to the above method, and the laying of other layers of geogrid

shall be carried out according to the same method and steps. After

the grid is laid, the upper embankment will be filled.

Factory and Equipment:

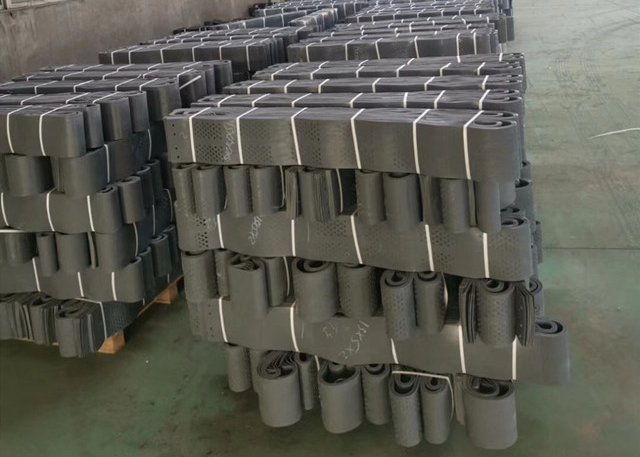

Product inventory:

Application:

Functioning by filling the pores with a three-dimensional honeycomb structure, the geocell cellular confinement system offers alternative solutions to geogrid material. Working with the logic of geogrid, geocell undertakes the tasks of reinforcement of geogrids on the ground and reinforcement on retaining walls. Differently, cellular confinement systems work by filling the cellular fillings.

Year of Registration: 2014

Place of Registration: China

Registrated Capital: CNY105,000,000.00

Briture Co., Ltd

was approved by Chinese Bureau of Commerce

Tel: +8615031817097

Whatsapp/Wechat: +8615031817097

Email: leo@hengquan-china.com

Website: www.plastic-geogrid.com

Download PDF: Catalog of Hengquan - geocell.pdf

|